Process for synthesizing quartz glass by horizontal silicon tetrachloride vapor deposition

A horizontal silicon tetrachloride, synthetic quartz technology, applied in glass forming, glass production, glass deposition furnace and other directions, can solve the problems of reducing the strength of the base rod to bear the weight, low material surface temperature, low material yield and other problems , to improve the strength and anti-devitrification properties, increase the high temperature area, and improve the deposition environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

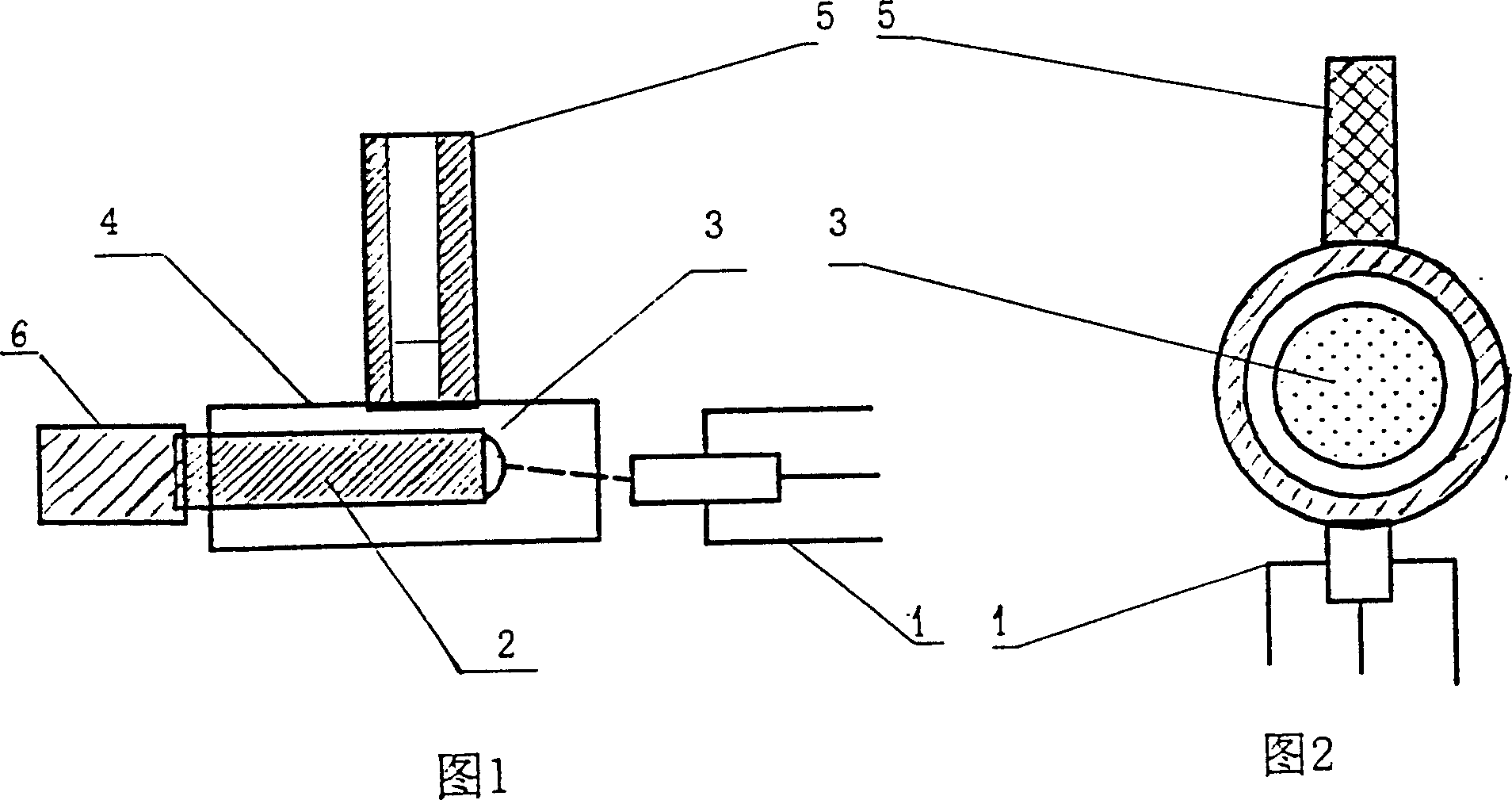

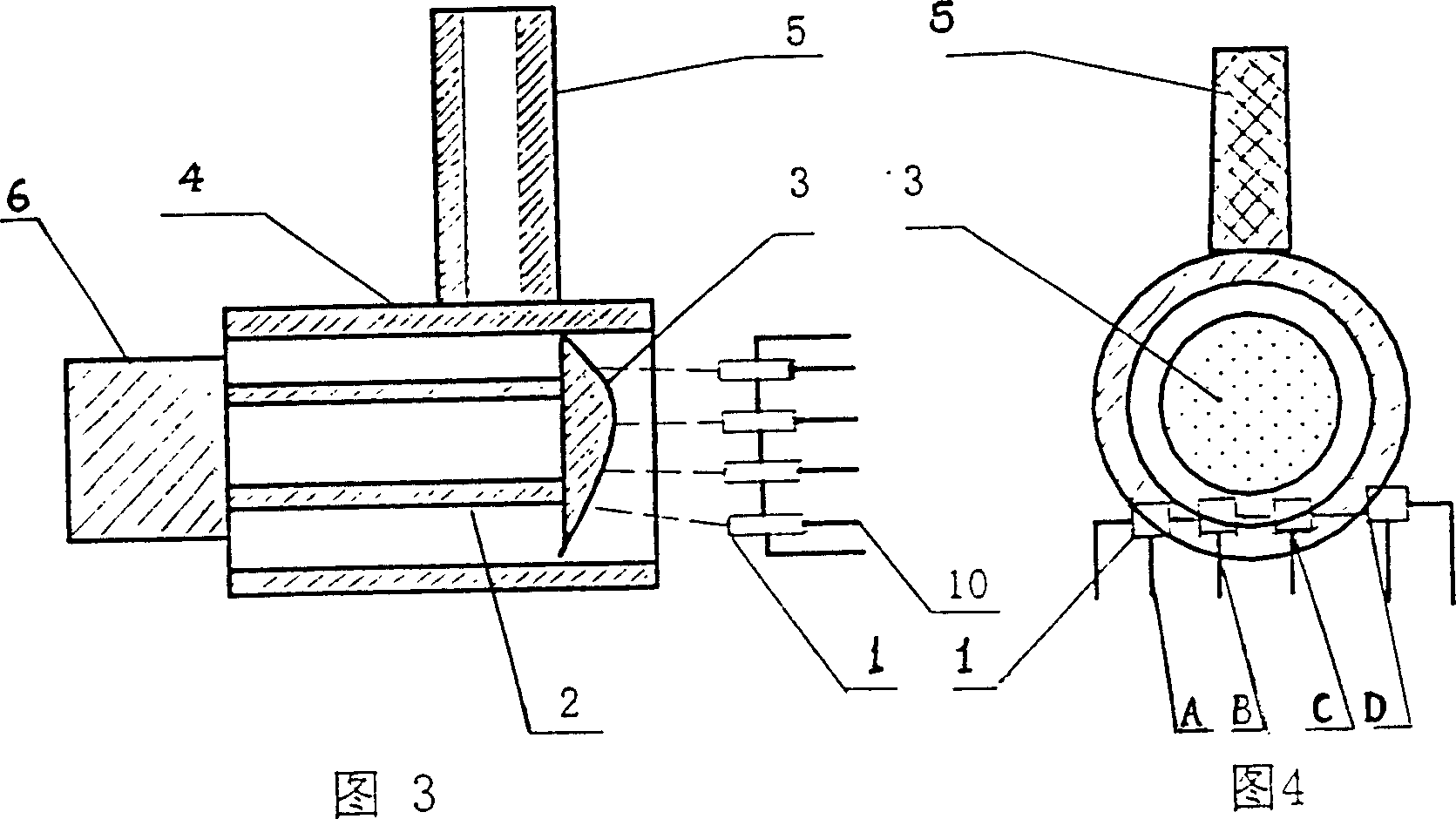

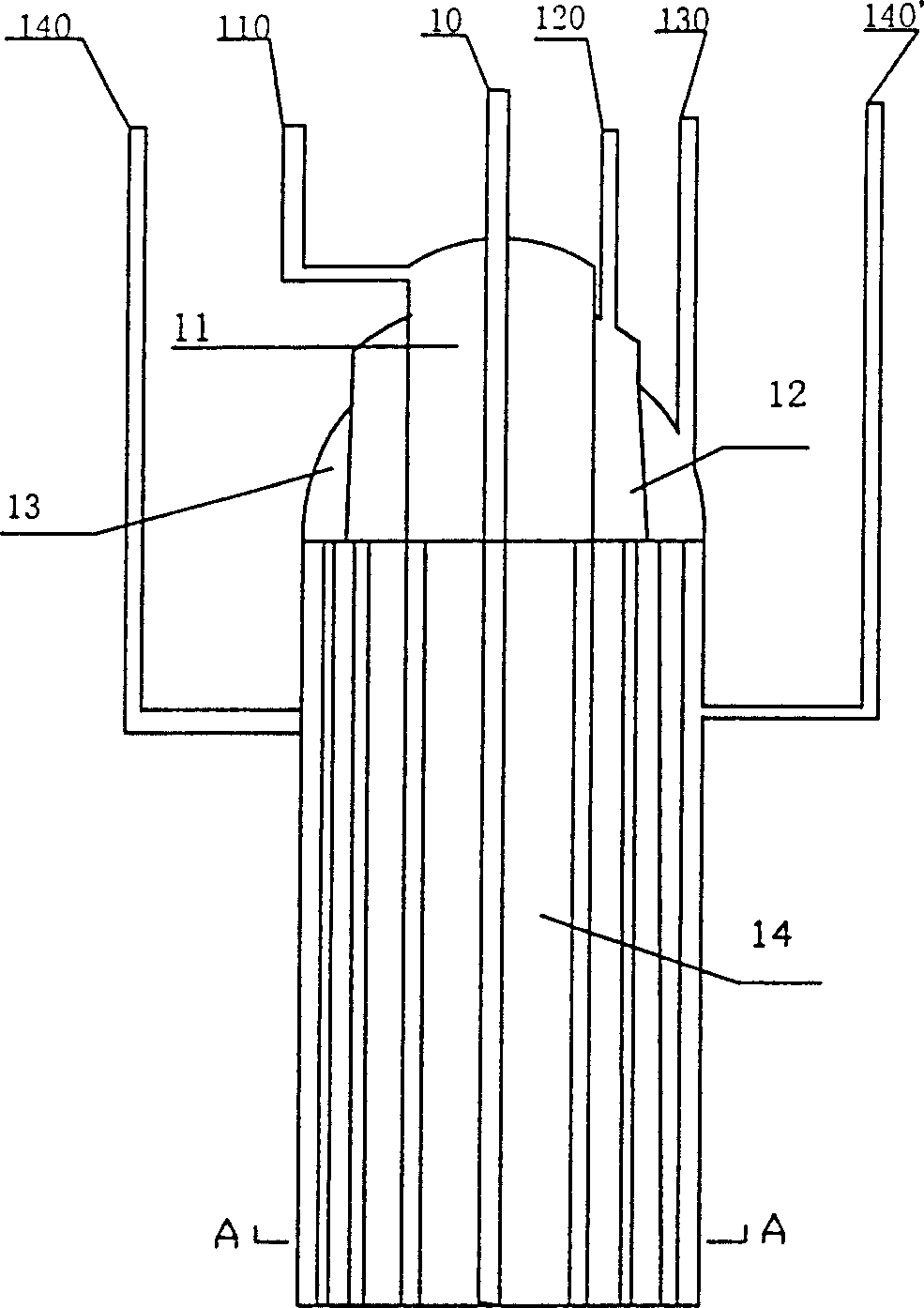

[0024] The invention provides a method for synthesizing quartz glass by horizontal silicon tetrachloride vapor deposition with multiple burners. In this method, the synthesis mechanism is the same as that of the existing horizontal process: in the burner, hydrogen and oxygen are burned to generate water vapor, Water vapor then reacts with gaseous silicon tetrachloride to produce silica particles; the resulting silica is deposited at high temperatures in a deposition furnace to form a quartz glass ingot. The specific process can be as follows: the gas with material flows through the purification drier to remove water vapor, after drying, the gas with material enters the drumming bottle through the deposition bottle (buffering effect), and the silicon tetrachloride liquid is bubbled and vaporized, and the gas with material and gaseous state The silicon tetrachloride mixed gas enters the lower feed pipe of the burner through the vaporization bottle; then the silicon tetrachloride ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com