Production method of synthetic silica glass ingot for large-size photomask substrates

A technology of synthetic quartz and production method, which is applied in glass production, glass molding, glass manufacturing equipment and other directions, can solve the problem that synthetic quartz glass ingots cannot grow normally, the growth efficiency of synthetic quartz glass ingots is low, and the feeding system cannot be stably supplied. and other problems to achieve the effect of avoiding unstable feeding, reducing energy consumption and improving growth efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

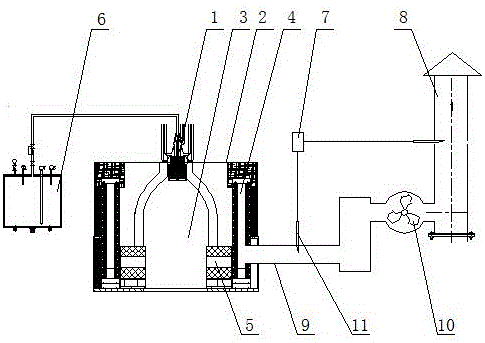

[0024] First, the furnace of the vertical deposition furnace is preheated by the hydrogen-oxygen burner 1. The vertical deposition furnace is composed of a furnace body 2 and a furnace 3 made of refractory materials. An annular air duct 4 is arranged between the body of furnace 2, and the top of the annular air duct 4 is provided with a plurality of air outlets, and the bottom of the annular air duct 4 is provided with a plurality of air inlets; the furnace 3 is provided with a top cover, and the top cover A hydrogen-oxygen burner 1 is installed in the middle part, and a furnace mouth 5 is arranged on one side of the furnace, and the furnace mouth 5 communicates with the annular air duct 4 .

[0025] The total amount of hydrogen and oxygen gas in the preheating process of the hydrogen-oxygen burner 1 is gradually increased from 3.5 cubic meters per hour. The method of increase is to observe the furnace temperature, first quickly raise the temperature to 800°C, and then graduall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com