Optical glass, glass preform, optical element and optical instrument

A technology of glass prefabrication and optical glass, which is applied in the direction of optical components, optics, instruments, etc., and can solve problems such as poor anti-devitrification performance, decreased yield rate, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0115]

[0116] In order to further clearly illustrate and illustrate the technical solution of the present invention, the following non-limiting examples are provided.

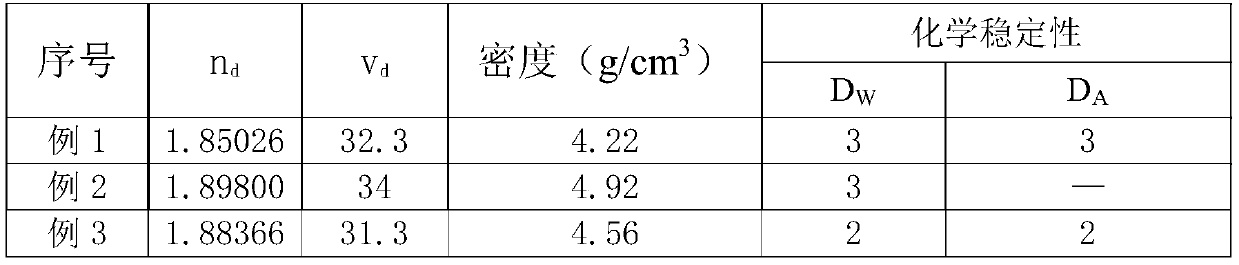

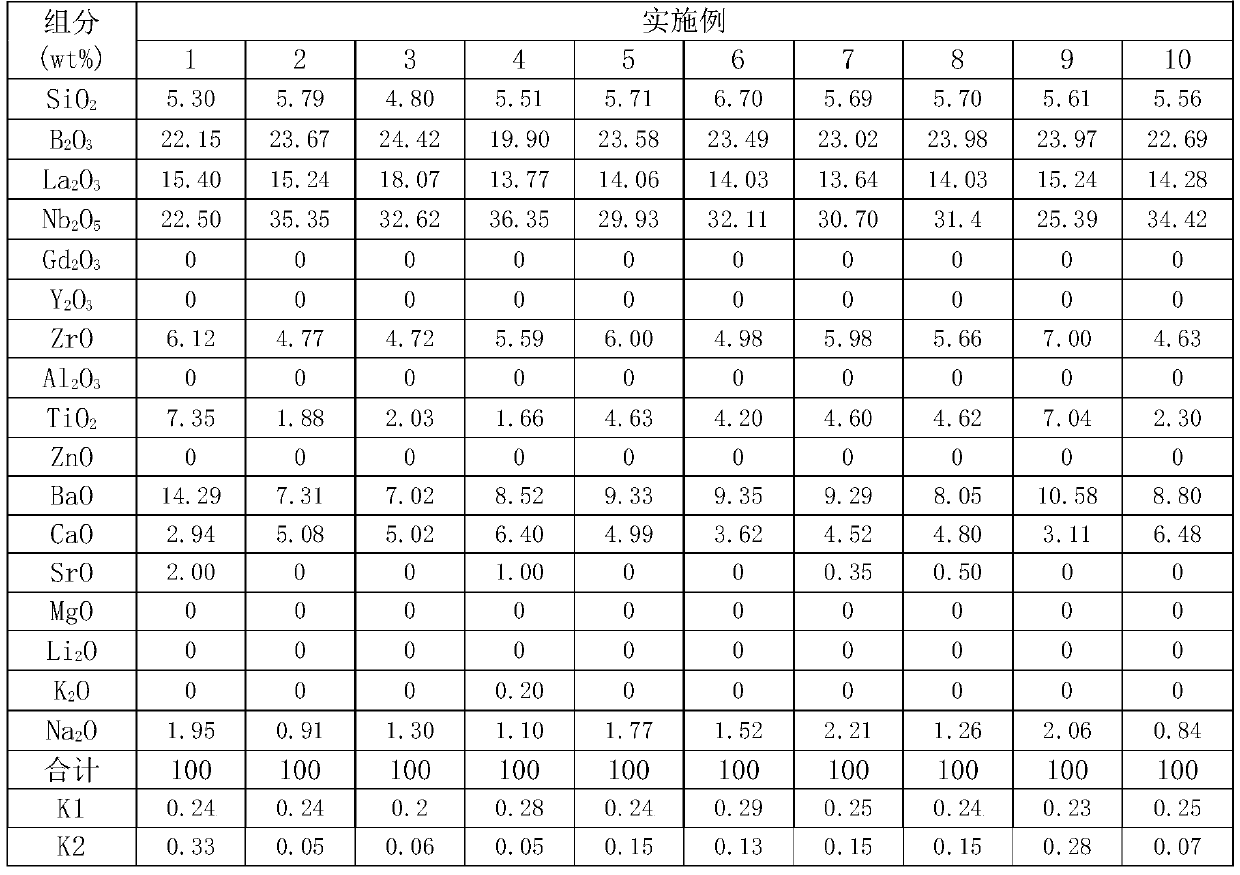

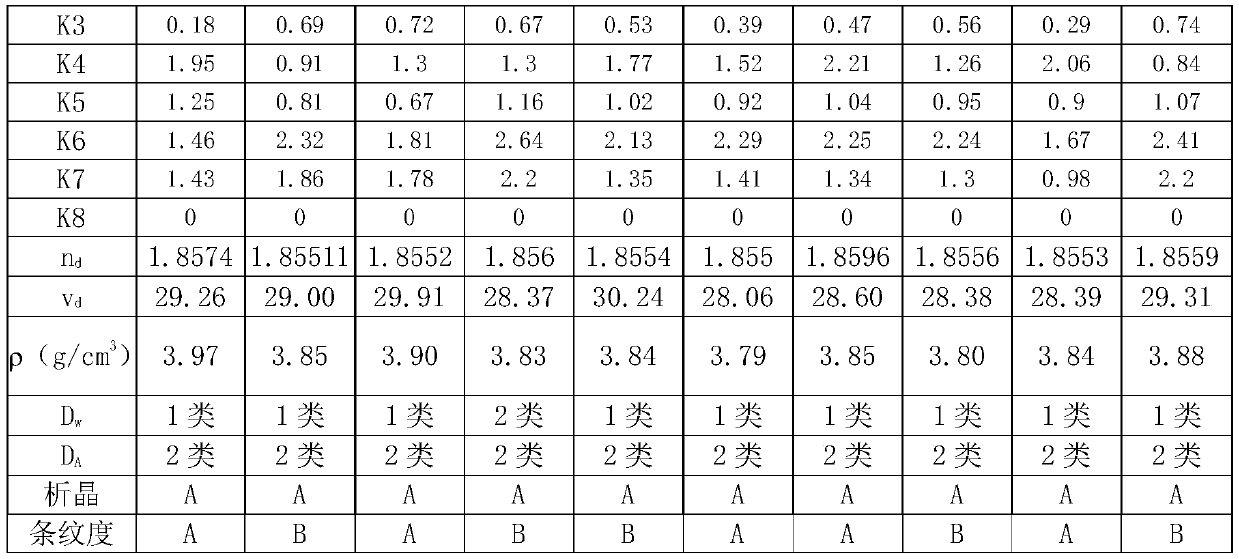

[0117] In this embodiment, the above-mentioned manufacturing method of optical glass was used to obtain the optical glass shown in Table 2-Table 3. In addition, the properties of each glass were measured by the test method described in the present invention, and the measurement results are shown in Tables 2 to 3. In Table 2 to Table 3, SiO 2 / B 2 o 3 The value is expressed in K1; TiO 2 / Nb 2 o 5 The value of is expressed in K2; the value of CaO / (BaO+SrO) is expressed in K3; Li 2 O+K 2 O+Na 2 O is represented by K4; (BaO+SrO+CaO) / (La 2 o 3 +Gd 2 o 3 +Y 2 o 3 ) is expressed in K5; Nb 2 o 5 / La 2 o 3 The value is expressed in K6; (CaO+BaO+SrO) / (Al 2 o 3 +ZrO 2 +TiO 2 ) is represented by K7; Li 2 O / (K 2 O+Na 2 O) is represented by K8. In the anti-devitrification performance test, if th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com