Processing method of device wafer with bump

一种加工方法、器件的技术,应用在半导体/固态器件制造、电气元件、电路等方向,能够解决晶片破损、粘接剂完全除去困难等问题,达到防止破损的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

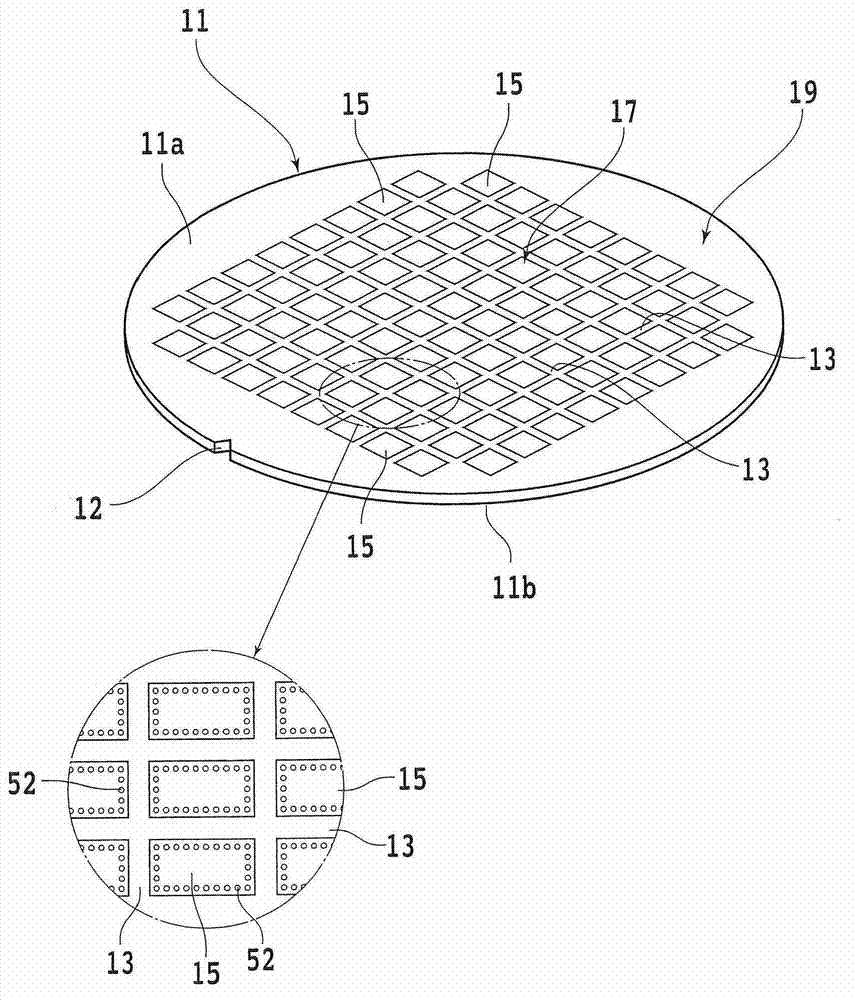

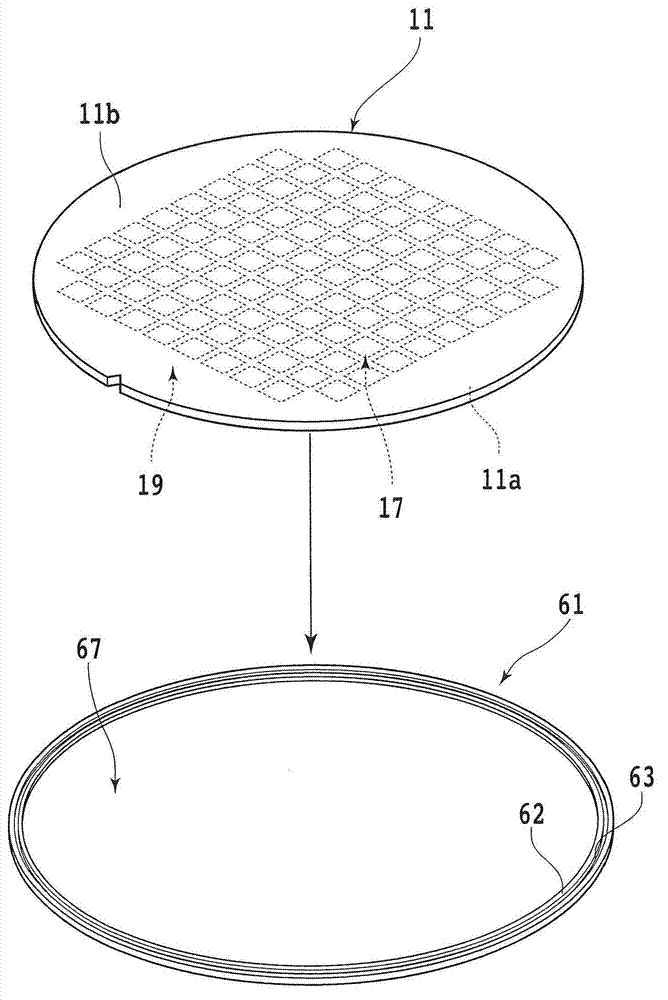

[0043] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 The shown device wafer 11 (hereinafter also simply referred to as "wafer 11") is formed of, for example, a silicon wafer with a thickness of 700 μm, and a plurality of dividing lines (streets) 13 are formed in a grid pattern on the surface 11a, and, Devices 15 are respectively formed in a plurality of regions divided by the plurality of planned dividing lines 13 .

[0044] Wafer 11 configured in this way includes device region 17 in which device 15 is formed and peripheral remaining region 19 surrounding device region 17 . Notches 12 are formed on the outer periphery of the wafer 11 as marks indicating the crystal orientation of the silicon wafer.

[0045] And, if figure 1 As shown in the enlarged view of , a plurality of protruding (spherical) bumps 52 are formed on four sides of each device 15 . The bumps 52 are configured to protrude from the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com