Electric pruning shears

A technology for pruning and scissors, which is applied in the field of rapid blade replacement structure, and can solve the problems of troublesome replacement work, cumbersome blade replacement steps, and small blade angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

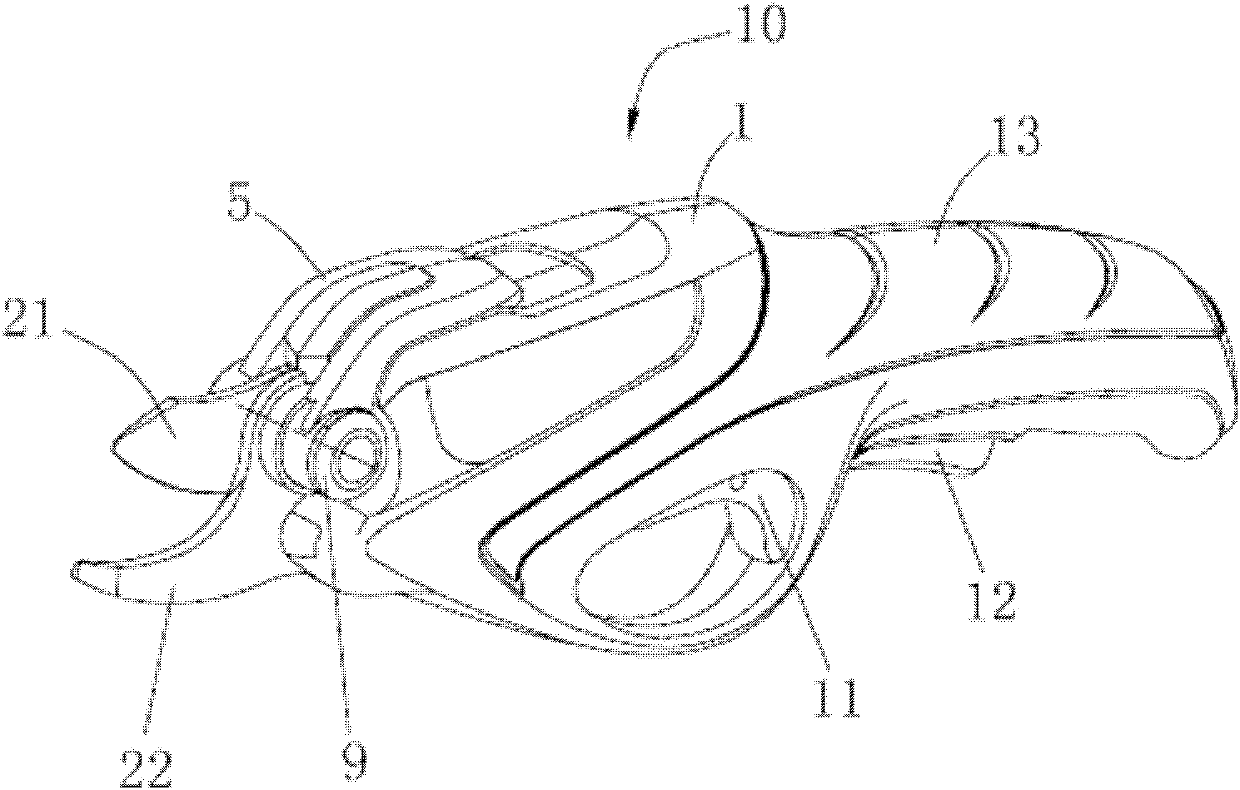

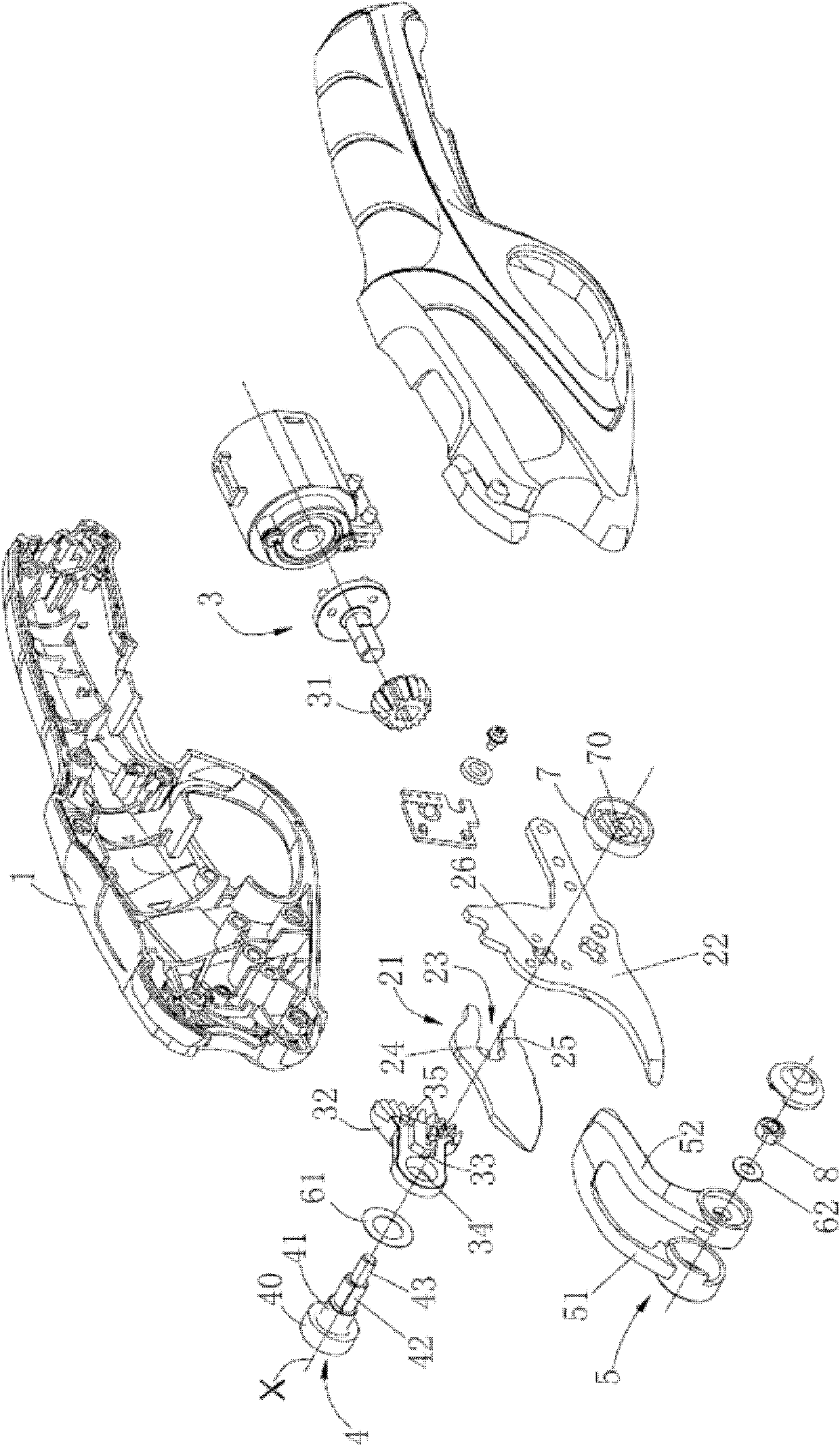

[0016] figure 1 It is a perspective view of electric pruning shears according to a preferred embodiment of the present invention. Such as figure 1 As shown, the electric pruning shears 10 includes a casing 1, which contains a motor 14, a transmission mechanism 3, a built-in battery (not shown in the figure), and a switch trigger 11 and a safety switch are installed below the casing 1. The switch 12 is used to control the opening and closing of the motor 14 . The rear of the cabinet 1 forms a grip portion 13 . Movable blade 21 and fixed blade 22 extend from the front end of casing 1, and fixed blade 22 is fixedly installed in casing 1 by screw or other means, and movable blade 21 is rotatably connected to fixed blade 22 by shaft (4), In this embodiment, the shaft (4) is embodied as a bolt.

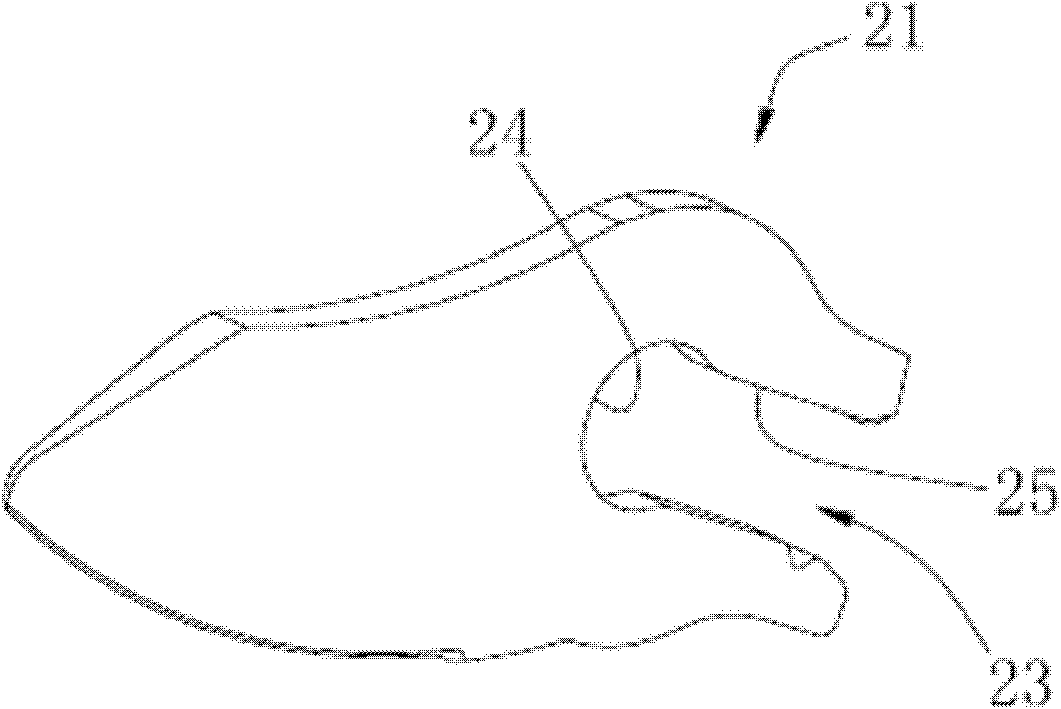

[0017] Such as figure 2 Shown, have groove 23 on the movable blade 22, and this groove 23 comprises the first groove 24 and the second groove 25 that pass through each other, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com