A composite proton exchange membrane for hydrogen fuel cell and a preparation method thereof

A proton exchange membrane, fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of low mechanical strength, poor dimensional stability, low proton conductivity, etc., and achieve improved proton conductivity and high structural regularity. , good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

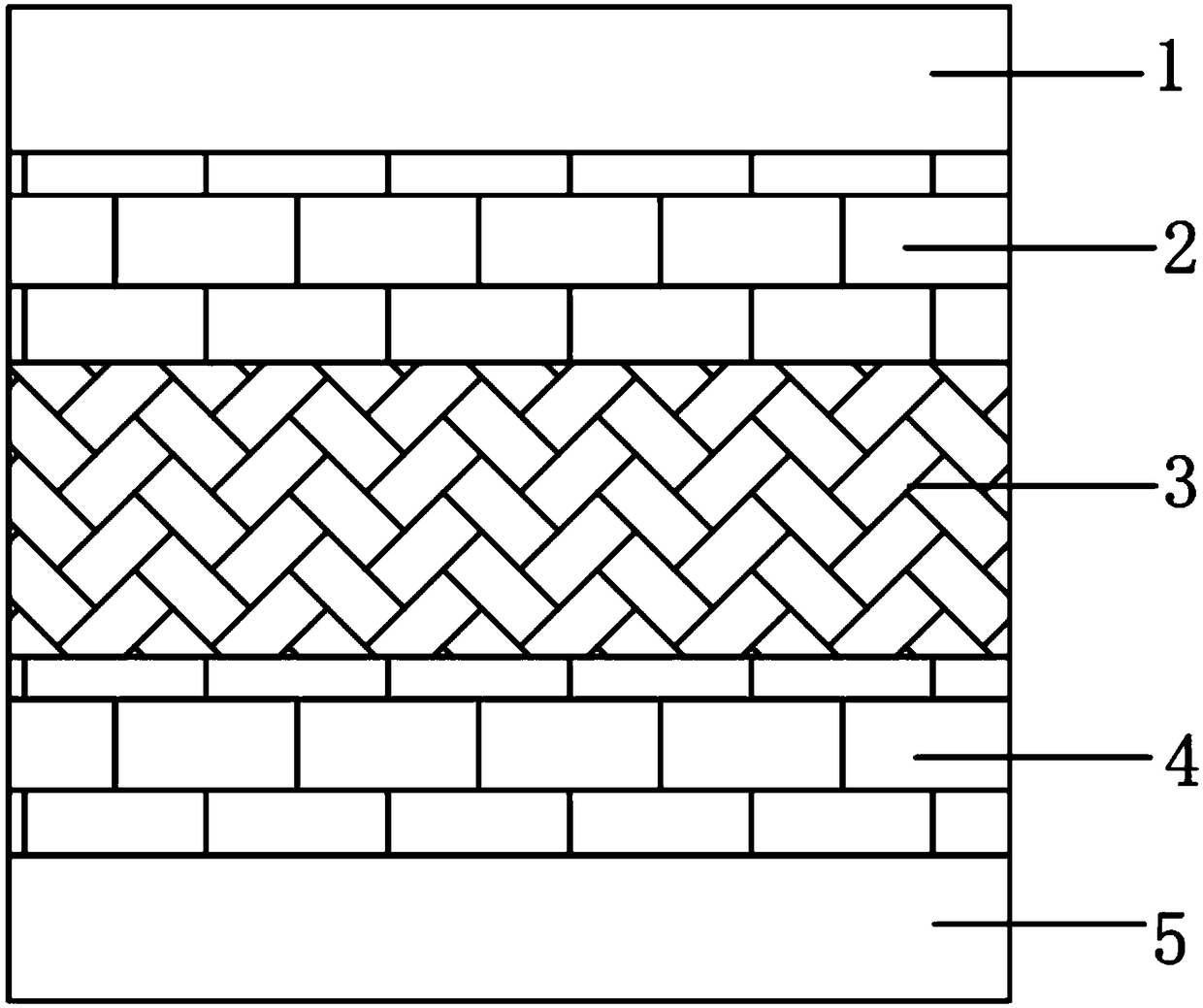

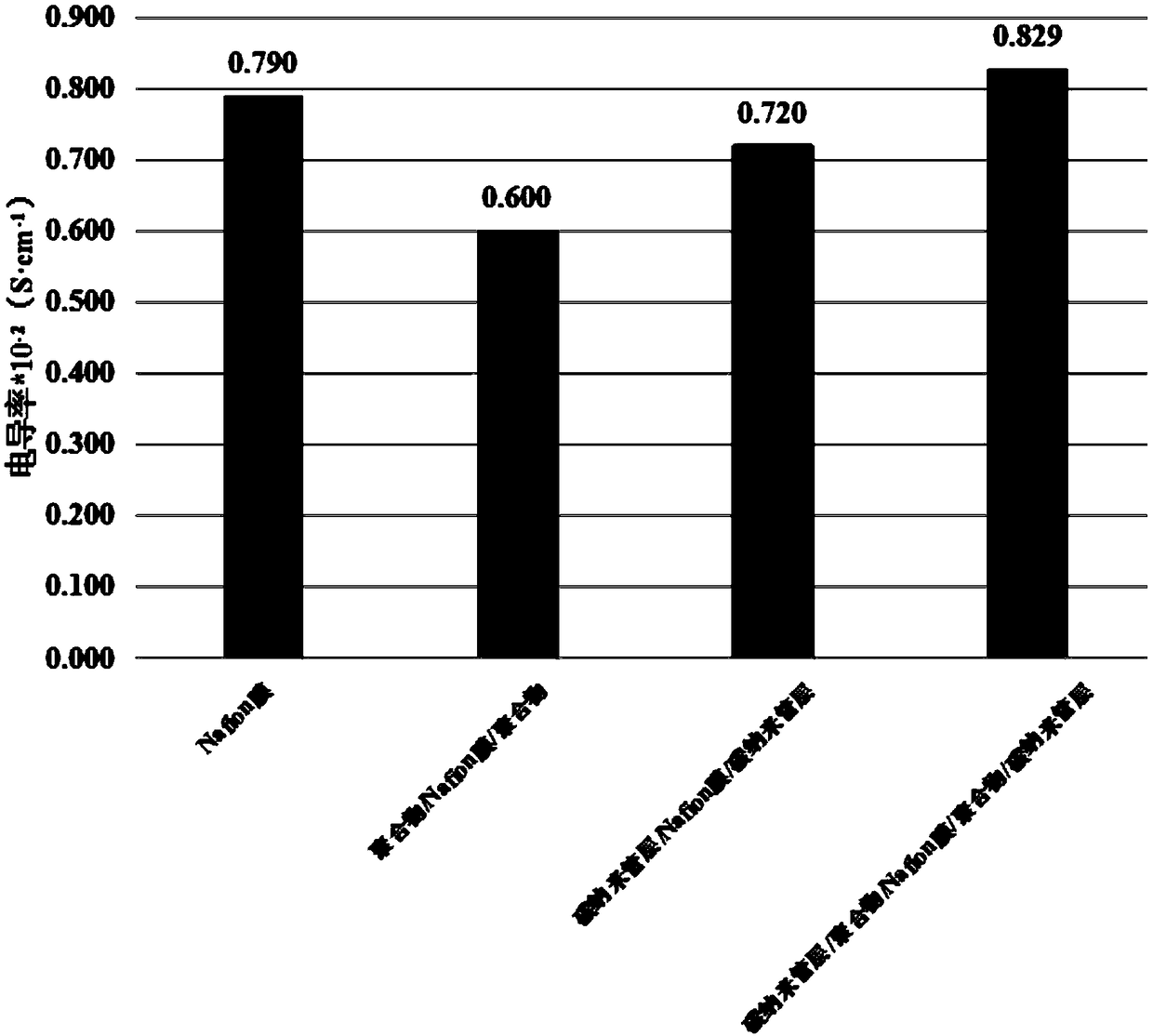

[0025] A composite proton exchange membrane for a hydrogen fuel cell and a preparation method thereof, comprising a Nafion membrane 3, a polymer, and a carbon nanotube layer, wherein the polymer includes a first polymer layer 2 and a second polymer layer 4, and the The carbon nanotube layer includes a first carbon nanotube layer 1 and a second carbon nanotube layer 5; the composite proton exchange membrane material is prepared by a layer-by-layer self-assembly method, and the Nafion membrane 3 is first immersed in a polymer solution , and then immersed in the solution of carbon nanotube dispersion, using this method to obtain a hamburger structure film of carbon nanotube film / polymer / Nafion / polymer / carbon nanotube film. Wherein, the Nafion membrane 3 is Du Pont company's 115 commercialized membranes, the pretreatment process is as follows:

[0026] (1) will 115 commercial membranes were placed in 80°C, 4wt.% H 2 o 2 Treat in the solution for 60 minutes to remove metal an...

Embodiment 2

[0035] A composite proton exchange membrane for a hydrogen fuel cell and a preparation method thereof, comprising a Nafion membrane 3, a polymer, and a carbon nanotube layer, wherein the polymer includes a first polymer layer 2 and a second polymer layer 4, and the The carbon nanotube layer includes a first carbon nanotube layer 1 and a second carbon nanotube layer 5; the composite proton exchange membrane material is prepared by a layer-by-layer self-assembly method, and the Nafion membrane 3 is first immersed in a polymer solution , and then immersed in the solution of carbon nanotube dispersion, using this method to obtain a hamburger structure film of carbon nanotube film / polymer / Nafion / polymer / carbon nanotube film. Wherein said Nafion film 3 is Du Pont company's through pretreatment process 115 commercialized membranes, the pretreatment process is as follows:

[0036] (1) will 115 commercial membranes were placed in 80°C, 5wt.% H 2 o 2 Treat in the solution for 50mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com