Manufacture method of solid electrolytic capacitor

A technology of solid electrolyte and manufacturing method, applied in solid electrolytic capacitors, capacitor parts, capacitor electrolytes/absorbents, etc., can solve the problems of long time, poor leakage current, damage to anode foil, etc., and achieve high capacity and low ESR Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

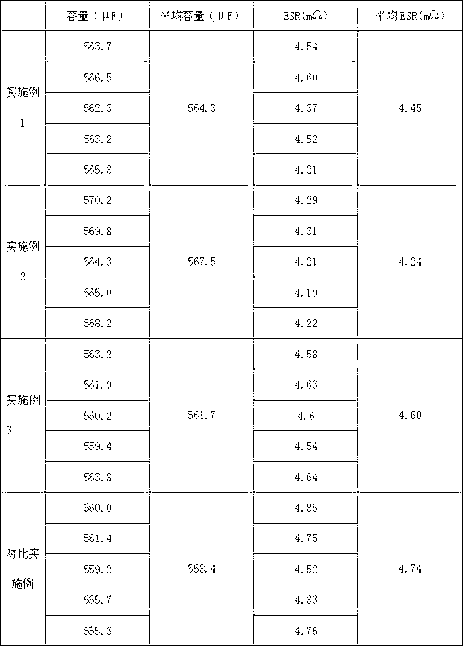

Examples

Embodiment 1

[0029] A preparation method of a solid electrolytic capacitor, specifically comprising the following steps:

[0030] Step 1: Interpose an isolation layer between the anode foil and the cathode foil which are made of valve metal and have an oxide film on the surface, and are wound into a core package, and fixed with adhesive tape;

[0031] Step 2: Immerse the core pack in the chemical forming solution, which is ammonium adipate aqueous solution, and apply voltage to carry out the chemical conversion repair, and the chemical conversion time is 15 minutes;

[0032] Step 3: Carry out carbonization treatment on the core bag, the carbonization temperature is 290°C, the carbonization time is 30 minutes, and then clean and dry;

[0033] Step 4: Put the dried core bag into the alcohol solution of the monomer for impregnation, the impregnation time is 2 minutes, and then dry it. Then put into the alcohol solution of iron p-toluenesulfonate and soak for 3 minutes;

[0034] Step 5: Put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com