Preparation method of water treatment advanced oxidation catalyst

An advanced oxidation and catalyst technology, applied in the field of water treatment, can solve the problems of high preparation cost, low activity, short service life, etc., and achieve the effect of improving service life, improving catalytic activity and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

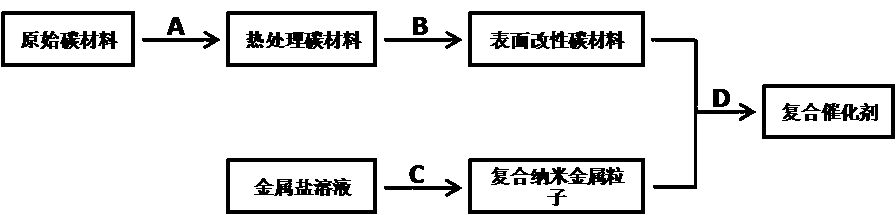

[0022] The invention provides a method for preparing an advanced oxidation catalyst for water treatment, which mainly includes the following four steps:

[0023] (1) In the first step, the original carbon material is subjected to high-temperature heat treatment at 2000-3000 ° C for 6-24 h before being used;

[0024] (2) In the second step, the carbon material treated in the first step is placed in a chitosan solution with a mass concentration of 0.1%~2%, wherein the mass ratio of carbon material to chitosan is 0.1~5:1, and stirred 0.5~2 h to mix evenly;

[0025] (3) The third step is to prepare composite nano-metal particles by chemical reduction method, wherein the reducing agent used in the chemical reduction method is one of sodium borohydride or hydrazine hydrate; the solvent is one of water or ethylene glycol; the solvent One of cetyltrimethylammonium bromide or polyvinylpyrrolidone is dissolved in the medium, and its mass concentration is 0.1-2%; the reaction temperatur...

Embodiment 1

[0030] The first step: the amorphous carbon material is heat-treated at 2800° C. for 12 hours under the condition of nitrogen protection.

[0031] Step 2: Weigh 100 mg of the above carbon material and add 100 mL of chitosan solution with a mass concentration of 0.5%, stir and mix for 1 hour, wash and dry. The dried solid was placed back in a beaker filled with 100 mL of water for use.

[0032] The third step: 72mg Fe(NO 3 ) 3 9H 2 O, 23mg Mn(NO 3 ) 2 4H 2 O, 19mg Cu(NO 3 ) 2 ·3H 2 O and 0.1g of cetyltrimethylammonium bromide were dissolved in 100 mL of water, and after mixing evenly, 1 mL of -1 sodium borohydride solution, reacted for 30min.

[0033] The fourth step: Measure 10 mL of the reacted solution in the third step and add it to the beaker in the second step, stir and react for 60 minutes, wash and filter to obtain the product catalyst.

Embodiment 2

[0035] The first step: a certain amount of bamboo carbon material is heat-treated at 2500° C. for 15 hours under the condition of nitrogen protection.

[0036] Step 2: Weigh 100 mg of the above carbon material and add 100 mL of chitosan solution with a mass concentration of 1%, stir and mix for 1.5 h, wash and dry. The dried solid was placed back in a beaker filled with 100 mL of water for use.

[0037] The third step: 108mg Fe(NO 3 ) 3 9H 2 O, 23mg Mn(NO 3 ) 2 4H 2 O and 0.2g of cetyltrimethylammonium bromide were dissolved in 100 mL of ethylene glycol, and after mixing evenly, 1 mL of -1 sodium borohydride solution, reacted for 45min.

[0038] The fourth step: Measure 10 mL of the reacted solution in the third step and add it to the beaker in the second step, stir and react for 120 minutes, wash and filter to obtain the product catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com