Heterocycle modified flexible hydrolysis-resistant polyester and preparation method thereof

A hydrolysis-resistant and flexible technology, applied in polyester coatings, coatings, etc., can solve the problems of polyester flexibility decline, limited raw material types, high cost and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

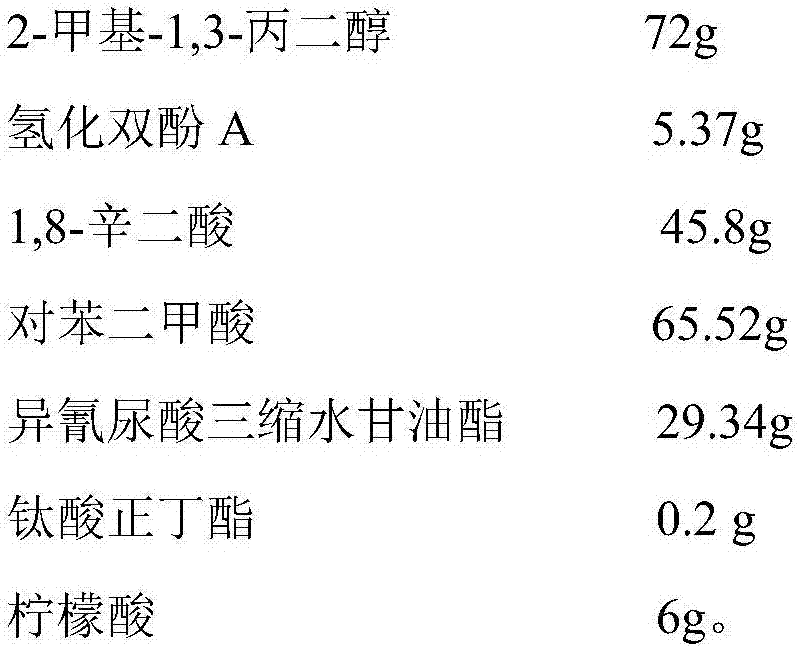

Embodiment 1

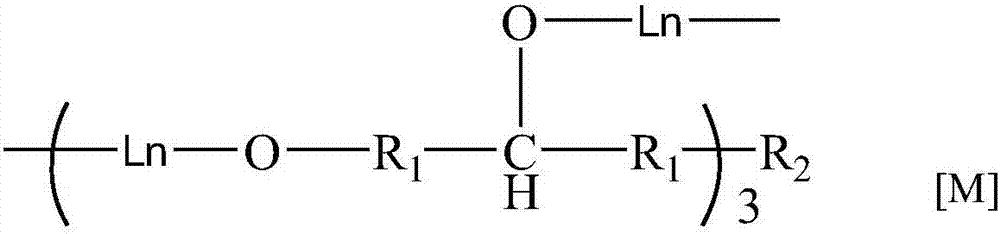

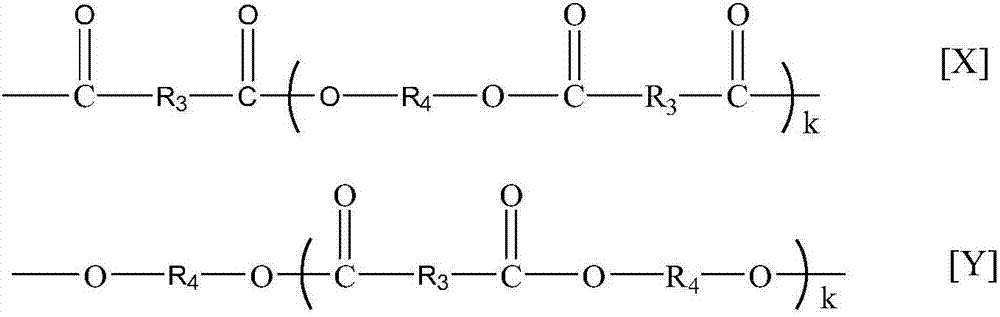

[0084] The heterocyclic modified flexible hydrolysis-resistant polyester provided in this embodiment is mainly prepared by the following method: selecting component A, component B and branched component C in the presence of a catalyst for esterification polycondensation reaction, and then In the later stage of the reaction, component D is added for reaction to obtain a flexible hydrolysis-resistant polyester with a six-membered branched island structure, wherein the proportion of the six-membered branched island structure in the flexible polyester structure is less than or equal to 13%.

[0085] Component A is selected from difunctional carboxylic acids. The secondary or tertiary carboxyl groups in the difunctional carboxylic acid account for no more than 20% of the total moles of the carboxylic acid. Component A is a dibasic acid, specifically 1,8-suberic acid With terephthalic acid.

[0086] Component B is selected from bifunctional alcohols. The primary hydroxyl groups in the bi...

Embodiment 2

[0097] The heterocyclic modified flexible hydrolysis-resistant polyester provided in this embodiment is mainly prepared by the following method: selecting component A, component B and branched component C in the presence of a catalyst for esterification polycondensation reaction, and then In the later stage of the reaction, component D is added for reaction to obtain a flexible hydrolysis-resistant polyester with a six-membered branched island structure, wherein the proportion of the six-membered branched island structure in the flexible polyester structure is ≤7%.

[0098] Component A is selected from difunctional carboxylic acids. The secondary or tertiary carboxyl groups in the difunctional carboxylic acid account for no more than 20% of the total moles of carboxylic acid. Component A is a dibasic acid, specifically sebacic acid and isophthalic acid. Formic acid and 1,4-cyclohexanedicarboxylic acid.

[0099] Component B is selected from bifunctional alcohols. The primary hydroxy...

Embodiment 3

[0109] The heterocyclic modified flexible hydrolysis-resistant polyester provided in this embodiment is mainly prepared by the following method: selecting component A, component B and branched component C in the presence of a catalyst for esterification polycondensation reaction, and then In the late stage of the reaction, the component D is added to react to obtain a flexible hydrolysis-resistant polyester with a six-membered branched island structure, wherein the proportion of the six-membered branched island structure in the flexible polyester structure is ≤2%.

[0110] Component A is selected from difunctional carboxylic acids. The secondary or tertiary carboxyl groups in the difunctional carboxylic acid account for no more than 20% of the total moles of carboxylic acid. Component A is a dibasic acid, specifically 1,6-adipic acid And terephthalic acid.

[0111] Component B is selected from bifunctional alcohols. The primary hydroxyl groups in the bifunctional alcohols account f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com