Printing method and system of DLP photocuring printer

A printer and light-curing technology, applied in 3D object support structure, additive manufacturing, processing data acquisition/processing, etc., can solve the problems of affecting printing efficiency and long printing time, so as to reduce exposure time, improve printing efficiency, and reduce printing time. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

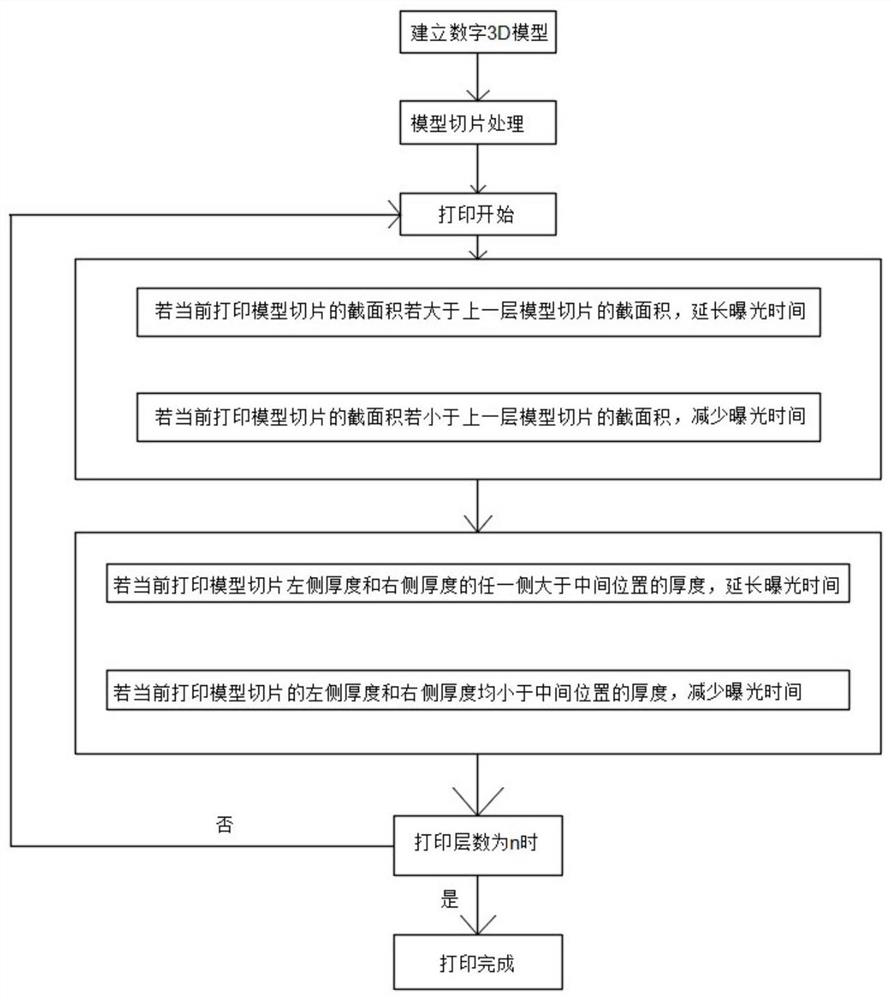

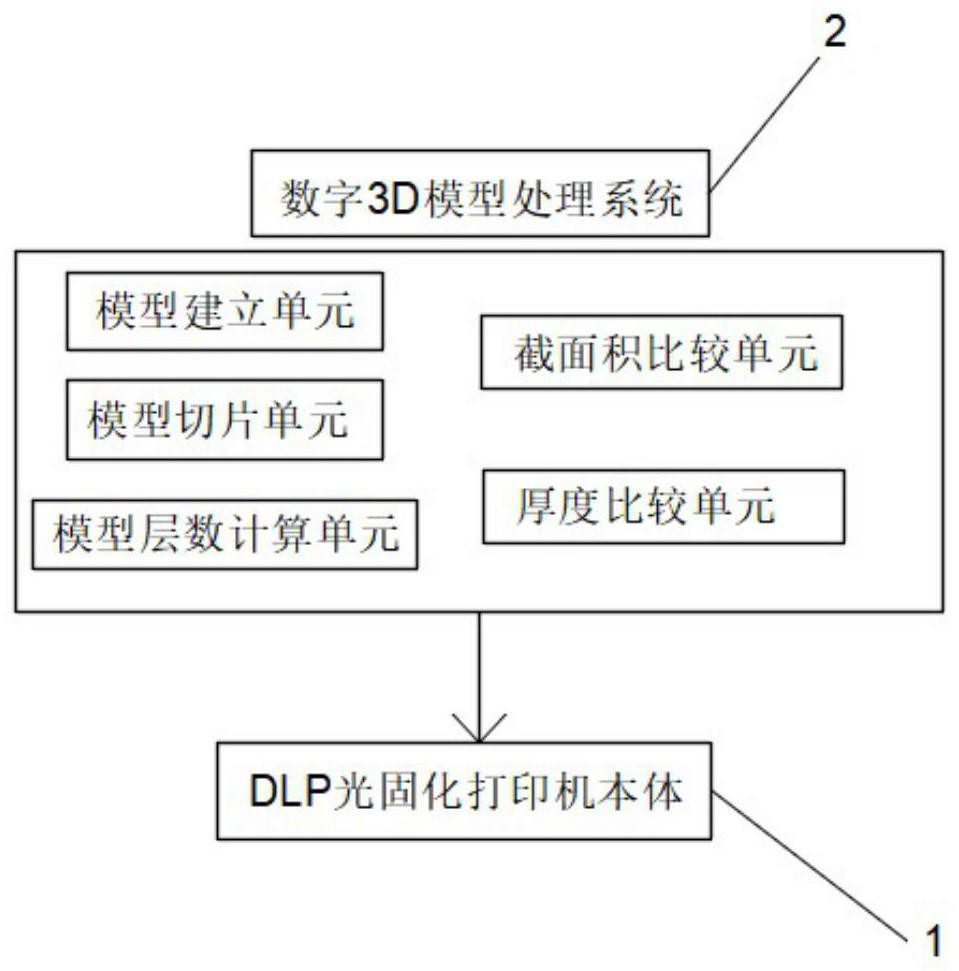

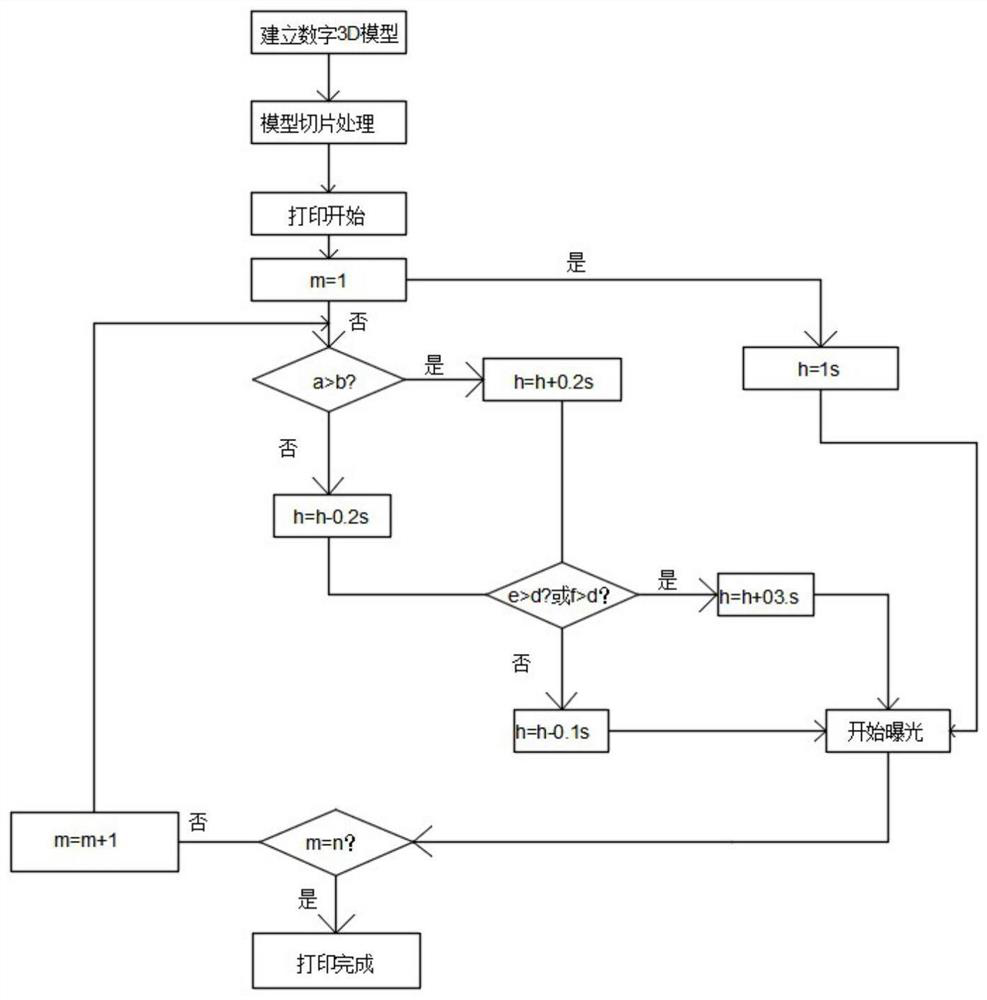

[0030] see figure 1 and image 3 , the present invention provides a technical solution: a printing method of a DLP light curing printer, comprising the following steps:

[0031] Step 1: Create a digital 3D model of the item to be printed;

[0032] Step 2: slice the digital 3D model to obtain multi-layer model slices, and the number of model slices is n;

[0033] Step 3: From the bottom to the top of the digital 3D model, start printing from the first layer according to the model slice. The current number of printing layers is m, the exposure time is h, and h is 1s.

[0034] Step 4: Calculate the cross-sectional area of each layer of model slices, the cross-sectional area of the current printed model slice is a, the cross-sectional area of the previous layer of printed model slices is b, and calculate the thickness d of the middle position of each layer of model slices, and use The middle position of the model slice is scanned to both ends to obtain the thickness e on ...

Embodiment 2

[0047] see figure 1 and image 3 , the present invention provides a technical solution: a printing method of a DLP light curing printer, comprising the following steps:

[0048] Step 1: Create a digital 3D model of the item to be printed;

[0049] Step 2: slice the digital 3D model to obtain multi-layer model slices, and the number of model slices is n;

[0050] Step 3: From the bottom to the top of the digital 3D model, start printing from the first layer according to the model slice. The current number of printing layers is m, the exposure time is h, and h is 1s.

[0051] Step 4: Calculate the cross-sectional area of each layer of model slices, the cross-sectional area of the current printed model slice is a, the cross-sectional area of the previous layer of printed model slices is b, and calculate the thickness d of the middle position of each layer of model slices, and use The middle position of the model slice is scanned to both ends to obtain the thickness e on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com