Method for forming cured coating film

A coating method and film coating technology, which is applied in the direction of photoplate making process coating equipment, etc., can solve the problems of inability to fill blind guide holes, flow of photosensitive resin composition, uneven thickness of cured coating film, etc., and achieve reliable filling Effects of embedding, shortening exposure time, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4、 comparative example 1~3

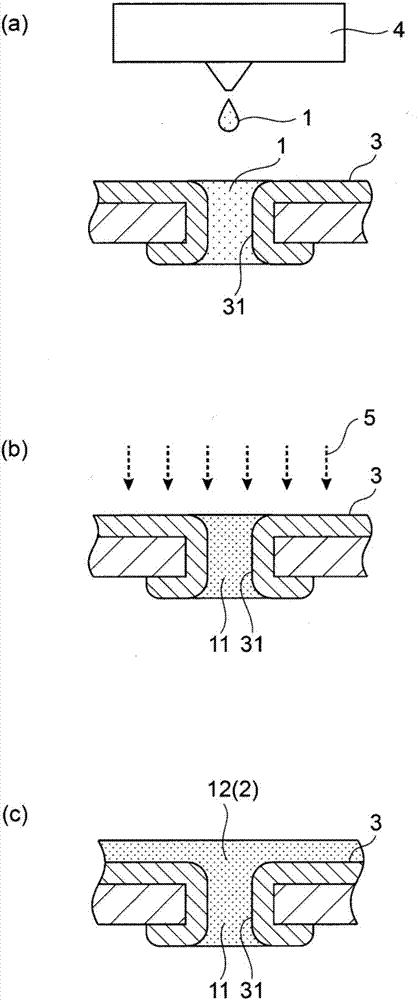

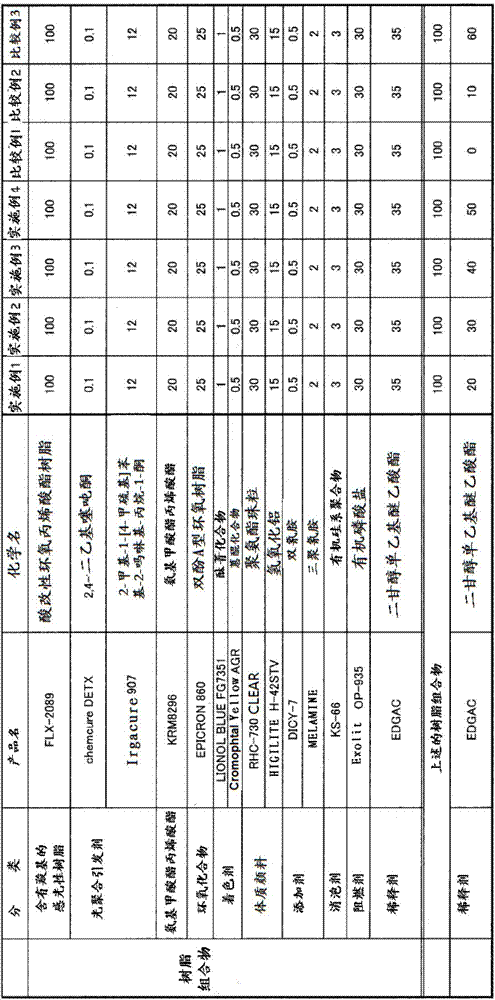

[0081] The components shown in the following Table 1 were blended in the compounding proportions shown in the following Table 1, mixed and dispersed at room temperature using a three-roll mill to prepare a resin composition, and a predetermined amount was added to the resin composition. diluent, and prepared the photosensitive resin composition used in Examples 1-4 and Comparative Examples 1-3. Then, the prepared photosensitive resin composition was apply|coated as follows, and the test piece was produced.

[0082] 【Table 1】

[0083]

[0084] Test piece production process

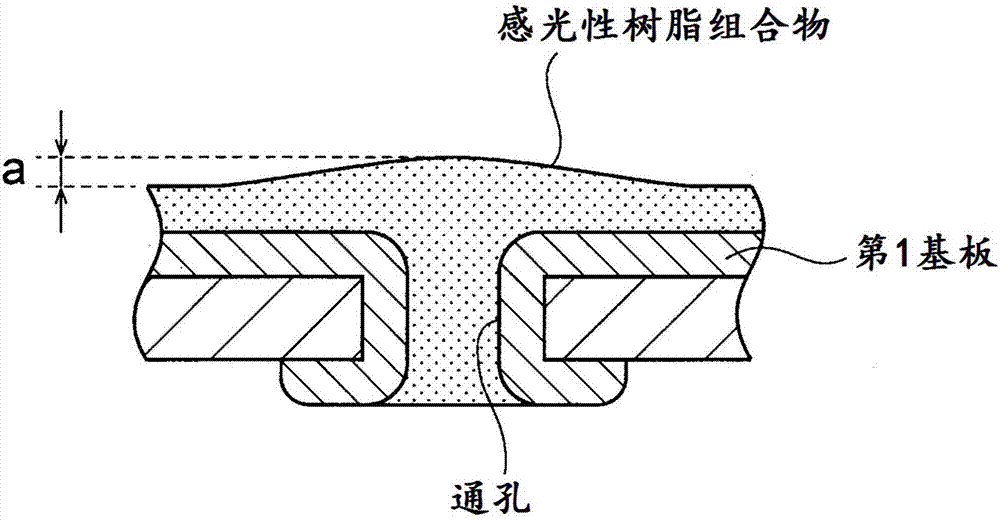

[0085] Substrate: set with inner diameter 1st substrate with a 70μm deep through-hole, provided with an inner diameter 2nd substrate with 70μm deep blind vias

[0086] Surface treatment: acid treatment (5 mass % sulfuric acid aqueous solution)

[0087] After the surface treatment, the photosensitive resins of Examples 1 to 4 and Comparative Examples 2 to 3 were dotted one by one using a jet dispen...

Embodiment 5~11、 comparative example 4

[0117] Next, as the UV irradiation machine used in the first curing process, instead of the above-mentioned UV irradiation machine using a metal halide lamp as a light source, an exposure device (manufactured by USHIO INC., model UX-2123SM) using an ultra-high pressure mercury lamp as a light source was used. ), so that the exposure amount of the first curing treatment becomes 10-100mJ / cm 2 Other than that, it carried out similarly to Example 3. That is, in Examples 5-11, the cured coating film was formed using the photosensitive resin composition of Example 3. The wavelengths of the ultra-high pressure mercury lamps are 365 nm, 385 nm, and 405 nm. Using ultra-high pressure mercury lamp to 30mJ / cm 2 The exposure time of the exposure is less than 1 second.

[0118] In Examples 5 to 11, the wavelength and exposure amount of the ultra-high pressure mercury lamp, and the results of via hole filling performance, blind via hole filling property, and coating film uniformity as the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com