High-performance asphalt pavement regenerant and preparation method thereof

A technology for asphalt pavement and rejuvenating agent, applied in building components, building insulation materials, buildings, etc., can solve the problems of poor performance improvement, poor penetration and repair effect, etc., to improve the miscibility effect, improve long-term aging performance, improve Effects of deformation and sticking behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a high-performance asphalt pavement regeneration agent, which is made of the following raw materials in parts by weight: 60 parts of the activation component, 10 parts of the permeation component, 13 parts of the plasticizing component, modified The component is 13 parts and the anti-aging component is 4 parts.

[0037] specific:

[0038] The activation component is made by mixing 1,4-butanediol, 1,5-pentanediol, ethylene glycol ether acetate and 1-octanol in a weight ratio of 1:2:0.5:1;

[0039] The penetrating component is made by mixing non-ionic wetting agent, dispersing agent and wetting and dispersing agent in a weight ratio of 1:2:1;

[0040] The plasticizing component comprises tung oil, palm oil, cedar oil, tea seed oil, dibutyl maleate, dianhydride and catalyst iodine and is made in a weight ratio of 4:2:3:2:1:1:1;

[0041] The modified component is made by mixing solid resin, adhesion promoter and tetrabutyl titanate in a weight rat...

Embodiment 2

[0050] This example provides a high-performance asphalt pavement regeneration agent, which is made of the following raw materials in parts by weight: 70 parts of the activation component, 5 parts of the penetrating component, 10 parts of the plasticizing component, modified The component is 9 parts and the anti-aging component is 6 parts.

[0051] Specifically, the raw material ratio and preparation method of the activating component, penetrating component, plasticizing component, modifying component and anti-aging component are the same as in Example 1.

[0052] The preparation method of the high-performance asphalt pavement rejuvenation agent in this embodiment is the same as the preparation method of the high-performance asphalt pavement rejuvenation agent in Example 1.

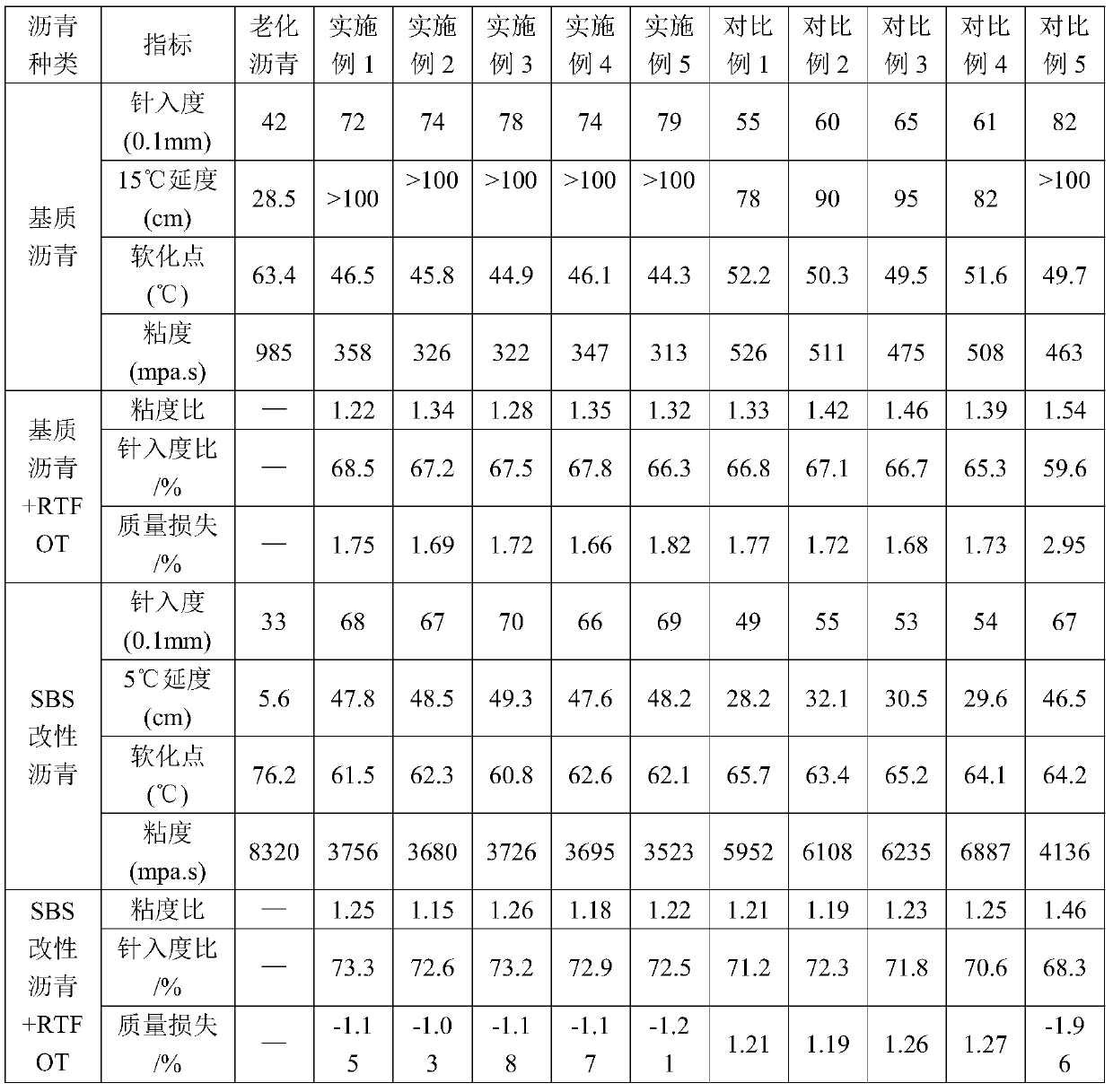

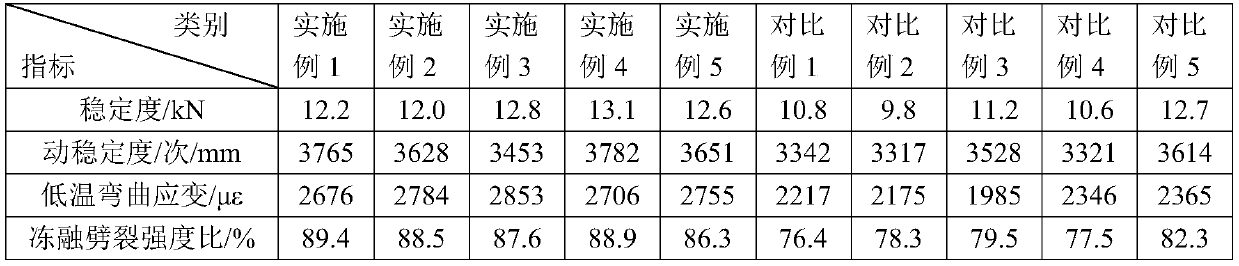

[0053] See Table 1 for the performance test results of this embodiment.

Embodiment 3

[0055] This example provides a high-performance asphalt pavement regeneration agent, which is made of the following raw materials in parts by weight: 65 parts of the activation component, 8 parts of the penetrating component, 15 parts of the plasticizing component, modified The component is 8 parts and the anti-aging component is 4 parts.

[0056] Specifically, the raw material ratio and preparation method of the activating component, penetrating component, plasticizing component, modifying component and anti-aging component are the same as in Example 1.

[0057] The preparation method of the high-performance asphalt pavement rejuvenation agent in this embodiment is the same as the preparation method of the high-performance asphalt pavement rejuvenation agent in Example 1.

[0058] See Table 1 for the performance test results of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com