Preparation method for waterborne PMMA composite coating diaphragm

A water-based coating and coating technology, applied in non-aqueous electrolyte batteries, electrical components, circuits, etc., can solve the problems of decreased product production efficiency, unfavorable product lightweight, increased thickness and weight, etc. Deformation and stability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

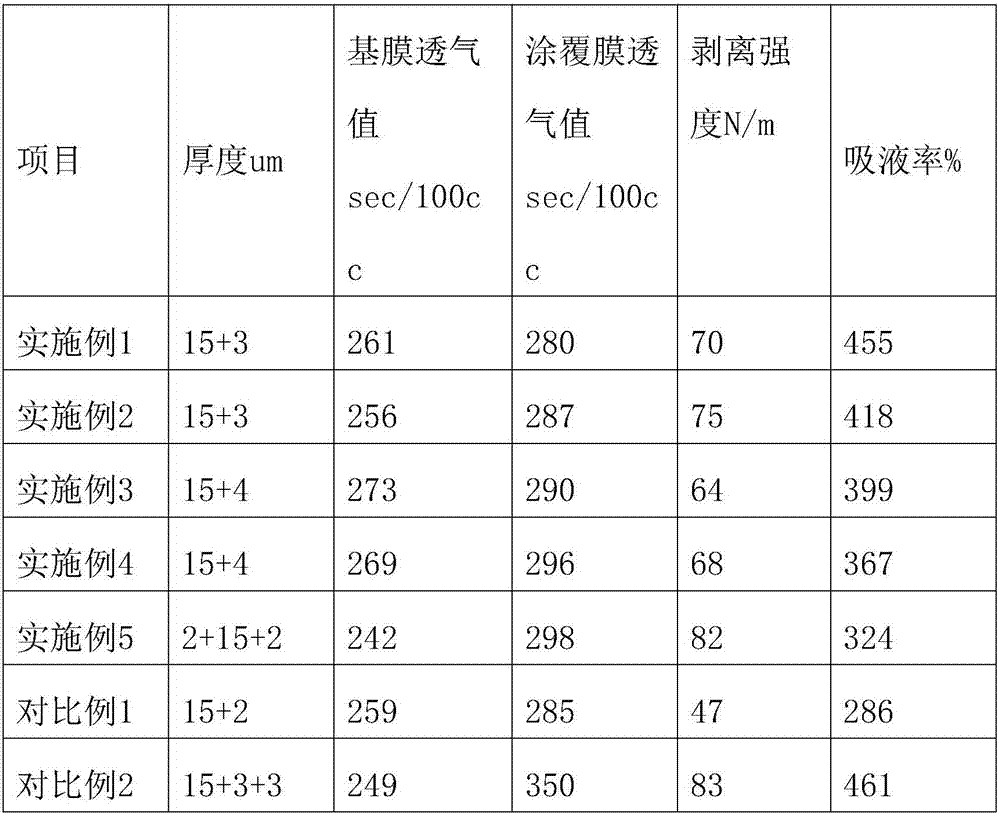

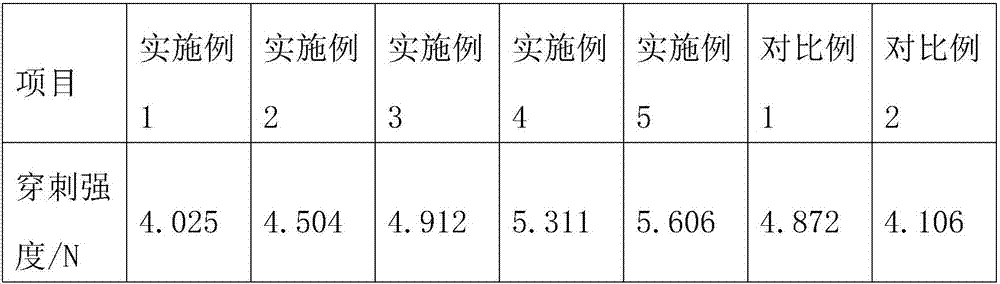

Examples

Embodiment 1

[0019] 1) Under a nitrogen atmosphere, add 25g of 1,2-diaminocyclohexane into 500g of tetrahydrofuran, stir until completely dissolved, then add 100g of PMMA with a molecular weight of 10,000g / mol, reflux for 6h, cool, filter with suction, and vacuum dry for 10h Finally, the modified PMMA powder is obtained.

[0020] 2) Add 80g of the above-mentioned modified PMMA powder to 500g of deionized water, mix and stir until completely dissolved, then add 200g of alumina powder, mix and stir at 30-50°C until the powder is evenly dispersed, finally add 10g of CMC, mix well and ball mill 0.5 ~2h to obtain aqueous mixed slurry. The above water-based mixed slurry is coated on one side of the 15 μm PP base film by anilox roller coating to form a water-based coating, and then dried in an oven at 30-80°C for 1-5 minutes to obtain the product. The thickness of the water-based coating is 4 μm.

Embodiment 2

[0022] 1) Under a nitrogen atmosphere, add 50g of 1,6-diaminocyclohexane into 500g of tetrahydrofuran, stir until completely dissolved, then add 25g of methyl methacrylate and ethylacrylic acid copolymer with a molecular weight of 50,000g / mol, and reflux the reaction 5h, cooling, suction filtration, obtain modified PMMA copolymer powder after vacuum drying 10h;

[0023] 2) Add 80g of the above-mentioned modified PMMA copolymer powder to 500g of deionized water, mix and stir until completely dissolved, then add 100g of magnesium oxide powder, mix and stir at 30-50°C until the powder is evenly dispersed, and finally add 10g of sodium alginate, Mix evenly and ball mill for 0.5-2 hours to obtain an aqueous mixed slurry. The above water-based mixed slurry is coated on one side of the 15 μm PP base film by roll coating to form a water-based coating, and then dried in an oven at 30-80°C for 1-5 minutes to obtain the product. The thickness of the water-based coating is 4 μm.

Embodiment 3

[0025] 1) Under a nitrogen atmosphere, add 100g of 1,2-diaminocyclopentane into 500g of tetrahydrofuran, stir until completely dissolved, then add 200g of methyl methacrylate and ethyl methacrylate copolymer with a molecular weight of 80000g / mol, Reflux reaction for 7h, cooling, suction filtration, and vacuum drying for 10h to obtain modified PMMA copolymer powder;

[0026] 2) Add 80g of the above-mentioned modified PMMA copolymer powder to 500g of deionized water, mix and stir until completely dissolved, then add 200g of magnesium hydroxide powder, mix and stir at 30-50°C until the powder is evenly dispersed, and finally add 10g of polyvinyl alcohol , mixed evenly and ball milled for 0.5-2 hours to obtain an aqueous mixed slurry. The above-mentioned water-based mixed slurry is coated on one side of the 15 μm PP base film by solt-die coating method to form a water-based coating, and then dried in an oven at 30-80 °C for 1-5 minutes to obtain the product. The thickness of the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com