Asphalt reinforcing agent and application of asphalt reinforcing agent in modified heavy traffic asphalt

A technology for re-crossing asphalt and reinforcing agents, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of difficult to form stable modified asphalt, poor compatibility with SBS, and low softening point, etc., to improve asphalt. High temperature stability and low temperature cracking resistance, the effect of extending the service life of the road

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

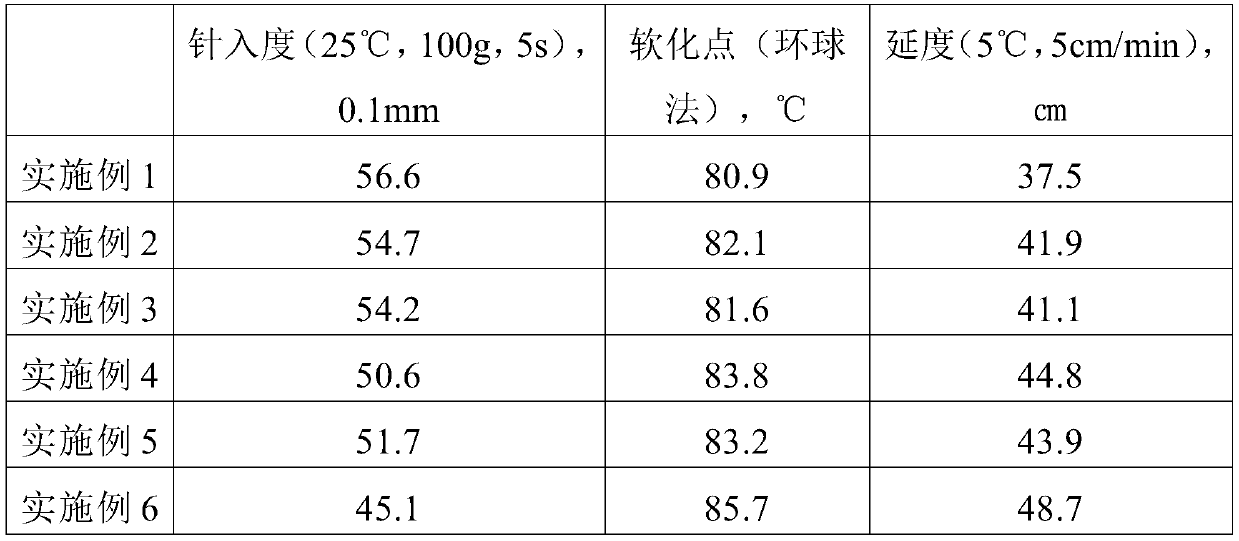

Examples

Embodiment 1

[0049] Modified heavy traffic asphalt raw materials (parts by weight): 90 parts of base asphalt, 5 parts of SBS, 6 parts of asphalt reinforcing agent, and 2 parts of stabilizer.

[0050] The stabilizer is PEG400.

[0051] The asphalt reinforcing agent is prepared by mixing functionalized mineral powder and basalt fiber at a mass ratio of 1:1. The functionalized mineral powder is modified vermiculite.

[0052] The preparation method of described modified vermiculite comprises the following steps, and described part is weight part:

[0053] (1) Add 8 parts of vermiculite powder to 50 parts of water, then add 4 parts of sodium stearate, stir at 200 rpm at 70°C for 50 minutes, centrifuge at 4000 rpm for 15 minutes, and dry the lower precipitate at 70°C To constant weight, obtain pretreated vermiculite powder;

[0054] (2) Add 4 parts of n-butyl borate and 3 parts of PEG10000 to 30 parts of ethanol, stir at 200 rpm for 30 minutes to obtain a mixed solution, mix 3 parts of acetic...

Embodiment 2

[0058] Modified heavy traffic asphalt raw materials (parts by weight): 90 parts of base asphalt, 5 parts of SBS, 6 parts of asphalt reinforcing agent, and 2 parts of stabilizer.

[0059] The stabilizer is PEG400.

[0060] The asphalt reinforcing agent is prepared by mixing functionalized mineral powder and modified basalt fiber at a mass ratio of 1:1.

[0061] The functionalized mineral powder is modified vermiculite.

[0062] The preparation method of described modified vermiculite comprises the following steps, and described part is weight part:

[0063] (1) Add 8 parts of vermiculite powder to 50 parts of water, then add 4 parts of sodium stearate, stir at 200 rpm at 70°C for 50 minutes, centrifuge at 4000 rpm for 15 minutes, and dry the lower precipitate at 70°C To constant weight, obtain pretreated vermiculite powder;

[0064] (2) Add 4 parts of n-butyl borate and 3 parts of PEG10000 to 30 parts of ethanol, stir at 200 rpm for 30 minutes to obtain a mixed solution, mix...

Embodiment 3

[0072] Modified heavy traffic asphalt raw materials (parts by weight): 90 parts of base asphalt, 5 parts of SBS, 6 parts of asphalt reinforcing agent, and 2 parts of stabilizer.

[0073] The stabilizer is PEG400.

[0074] The asphalt reinforcing agent is prepared by mixing functionalized mineral powder and modified basalt fiber at a mass ratio of 1:1.

[0075] The functionalized mineral powder is modified serpentine.

[0076] The preparation method of the modified serpentine comprises the following steps, and the parts are all parts by weight: 4 parts of sorbitan fatty acid esters are added to 80 parts of ethanol, stirred at 45° C. at 200 rpm for 10 Minutes, add 8 parts of serpentine powder, stir at 45°C at 200 rpm for 50 minutes, centrifuge at 4000 rpm for 15 minutes, dry the lower sediment at 70°C to constant weight, grind, and pass through a 300-mesh sieve to obtain modified Serpentine.

[0077] The preparation method of the modified basalt fiber comprises the following ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com