Modified asphalt mastic resin used for panel sealing layer, and preparation and application methods thereof

A technology of modified asphalt and mastic, which is applied in the field of water conservancy and hydropower engineering, can solve problems such as easy aging and cracking, poor construction conditions, and poor low-temperature performance, so as to improve the ability to resist low-temperature cracking, avoid high-temperature flow, and improve anti-corrosion aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The test results of the modified asphalt in Example 1 are shown in Table 2, and the test results of the mineral powder technical indicators used are shown in Table 3. After the raw materials are weighed, the modified asphalt matrix is dehydrated and heated to 160°C, and the mineral powder is heated to 100°C. After drying at ℃, it was added in proportion to the heated modified asphalt and mixed evenly to prepare the asphalt mastic of Example 1. The performance test indicators are shown in Table 4.

[0038] As can be seen from Table 4, the asphalt mastic sample prepared in Example 1 has good high-temperature flow resistance and low-temperature freeze-crack resistance.

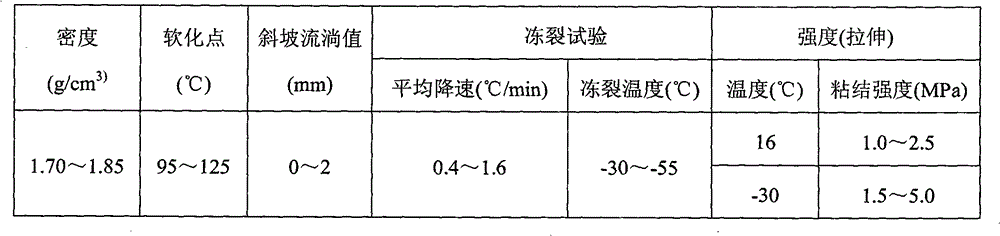

[0039] Modified asphalt technical index used in the embodiment 1 of table 2

[0040]

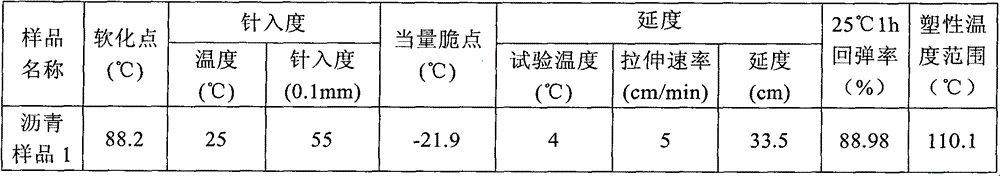

[0041] The ore powder technical index used in the embodiment 1 of table 3

[0042]

[0043] The asphalt mastic performance test index used in the embodiment 1 of table 4

[0044]

Embodiment 2

[0046] Embodiment 2 and embodiment 3 are two examples of the same modified asphalt matrix, the same mineral powder, and different proportions. The test results of modified asphalt are shown in Table 5, and the test results of the mineral powder technical indicators used are shown in Table 3. The raw materials are called After measuring well, dehydrate the modified asphalt matrix and heat it to 160°C, heat the mineral powder to 100°C and dry it, then add it in proportion to the heated modified asphalt and mix evenly to prepare Example 2 and Example 3 Asphalt mastic, its performance test indicators are shown in Table 6.

[0047] It can be seen from Table 6 that the samples of asphalt mastic prepared in Example 2 and Example 3 have good high-temperature flow resistance and low-temperature freeze-crack resistance.

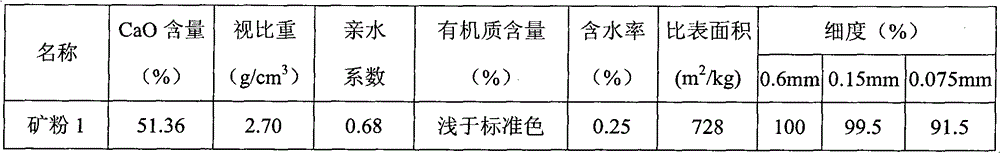

[0048] Modified asphalt technical indicators used in table 5 embodiment 2, embodiment 3

[0049]

[0050] Performance test index of asphalt mastic in table 6 embod...

Embodiment 4

[0053] The asphalt technical indicators in Example 4 are shown in Table 2, and the test results of mineral powder technical indicators are shown in Table 7. After the raw materials are weighed, the modified asphalt matrix is dehydrated and heated to 160°C, and the mineral powder is heated to 100°C for drying. Then add the heated modified asphalt in proportion and mix evenly to prepare the asphalt mastic. The performance test index of the asphalt mastic obtained in Example 4 is shown in Table 8.

[0054] It can be seen from Table 8 that the asphalt mastic sample prepared in Example 4 has good high-temperature flow resistance and low-temperature freeze-crack resistance.

[0055] The mineral powder technical index that table 7 embodiment 4 uses

[0056]

[0057] Table 8 Example 4 Asphalt mastic performance test index

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com