Prescription of fibre modified slurry sealing layer and construction method

A technology of slurry sealing and fiber modification, which is applied in the formulation and construction field of fiber-modified slurry sealing, can solve the problems of inability to guarantee the service life of the pavement, the damage to the pavement is not effectively controlled, and the strength of the foundation varies. , to achieve the effect of reducing maintenance costs, being beneficial to environmental protection and having a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A formula for fiber-modified slurry seal layer is composed of: graded ingredients 8211Kg, modified floating asphalt 944Kg, jet roving 24Kg and water 821Kg.

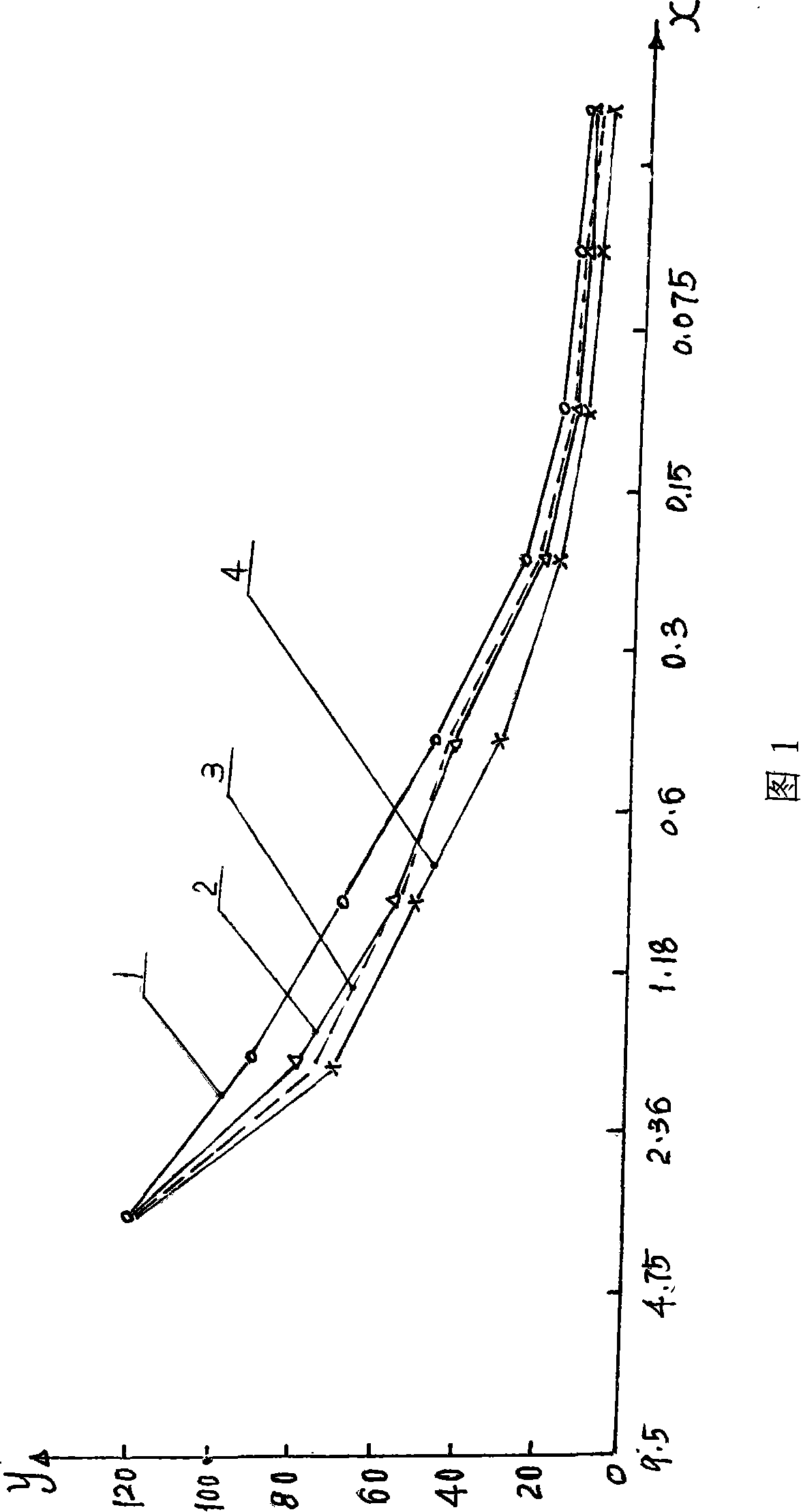

[0014] The construction method of the fiber-modified slurry seal layer is as follows: first, treat the road surface disease that needs to be maintained, clean the road surface, and fill the seriously damaged deep pit with sand; second, choose a wind-powered cutting machine that can spray roving and slurry sealer; thirdly, the ingredients are selected from stone powder with a diameter of 2.36mm or less, rice stones with a diameter of 2.36 to 4.75mm and aggregates with a diameter of 4.75mm to 9.5mm, according to the mixing grade of the slurry seal made in the laboratory The ratio of the batching ratio curve (see attached drawing 1), the mixed grading batching 8211Kg, the selected synthetic percentage curve 3 should be close to the standard grading neutral curve 2, must be in the standard grading upper limit curve 1 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com