Warm mix additive for asphalt mixture and preparation method thereof

A kind of asphalt mixture and additive technology, which is applied in the direction of building insulation materials, building components, buildings, etc., can solve the problem of low temperature tensile and brittle crack resistance of asphalt mixture, reduce the viscosity of modified asphalt at 175°C, and reduce the high temperature of asphalt Viscosity and other problems, to achieve the effect of reducing shear viscosity, strengthening mutual bonding force and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

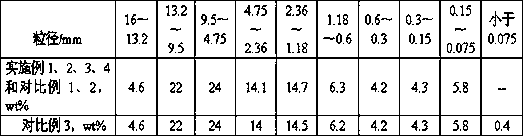

Embodiment 1

[0045] The mass percent of asphalt mixture warm mix additives is:

[0046] Powdered solids (including 70wt% inorganic components and 30wt% organic components): 82.6wt%;

[0047] Comb branched polybutadiene (molecular weight 6000): 2.5 wt%;

[0048] Fatty alcohol polyoxyethylene ether: 0.8wt%;

[0049] Rosin acid: 8.6wt%;

[0050] Zinc stearate: 5.5 wt%.

[0051] The preparation method of the powdery solids described in this example is as follows: oily sludge (wherein the oil content is 43wt%, and the solid content is 48wt%) is sent into the centrifuge, and at the same time, the flocculant, namely cocamide, is added to the centrifuge A mixture of propyl betaine and lignosulfonate (the mass ratio of the two is 2:1), the flocculant is added so that the final powdery solid contains 0.6wt% flocculant, and the oily sludge enters the extraction after centrifugation Process; the centrifuged oily sludge and the extractant are mixed according to the mass ratio of 1:40, and the press...

Embodiment 2

[0054] The mass percent of asphalt mixture warm mix additives is:

[0055] Powdered solids (including 70wt% inorganic components and 30wt% organic components): 59.3wt%;

[0056] Star branched styrene / butadiene copolymer (molecular weight 8600): 9.7 wt%;

[0057] Alkanolamide polyoxyethylene ether: 5.2 wt%;

[0058] Rosin acid: 3.8wt%;

[0059] Magnesium stearate: 22wt%.

[0060] The preparation method of the powdery solids described in this example is as follows: oily sludge (wherein the oil content is 43wt%, and the solid content is 48wt%) is sent into the centrifuge, and at the same time, the flocculant, namely cocamide, is added to the centrifuge A mixture of propyl betaine and lignosulfonate (the mass ratio of the two is 2:1), the flocculant is added so that the final powdery solid contains 0.6wt% flocculant, and the oily sludge enters the extraction after centrifugation Process; the centrifuged oily sludge and the extractant are mixed according to the mass ratio of 1:...

Embodiment 3

[0063] The mass percent of asphalt mixture warm mix additives is:

[0064] Powdered solids (among them, inorganic components 65wt%, organic components 35wt%): 78.9wt%;

[0065] Star branched polystyrene / (molecular weight 16500): 2.0 wt%;

[0066] Glyceryl monostearate: 2.3wt%

[0067] Rosin acid: 6.1wt%;

[0068] Cadmium stearate: 10.7wt%.

[0069] Put the powdery solids, star branched polystyrene, glyceryl monostearate, abietic acid, and cadmium stearate into the twin-screw extruder according to the proportioning ratio. The mixing temperature is 105°C, and the mixture is uniformly extruded. The finished product is granulated to obtain warm mix additive for asphalt mixture.

[0070] The preparation method of the powdery solids described in this example is as follows: send the oily sludge (in which the oil content is 69wt%, and the solid content is 24wt%) into the centrifuge, and at the same time add flocculant, namely fatty alcohol, to the centrifuge Polyoxyethylene ether...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com