Cooling type high-performance road marking hot melt coating for high-altitude area and preparation method thereof

A road marking, high-performance technology, applied in the direction of reflection/signal paint, coating, etc., can solve problems such as cracking and peeling, road marking paint optimization design, etc., achieve good economic and environmental benefits, improve UV resistance and low temperature Anti-cracking ability, effect of reducing fuel consumption and emission of harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method includes the following steps:

[0026] The binder, the filler, the pigment, the reflective material, the plasticizer, the elasticizer, the warm-mixing agent and the light-shielding agent are dry-mixed and uniformly mixed at 160° C. After heating for 15 minutes, when the coating is initially melted, the rheological agent is added to mix quickly and uniformly.

Embodiment 1

[0028] A preparation method of a cooling type high-performance road hot-melt marking paint in high-altitude areas, the specific steps are as follows:

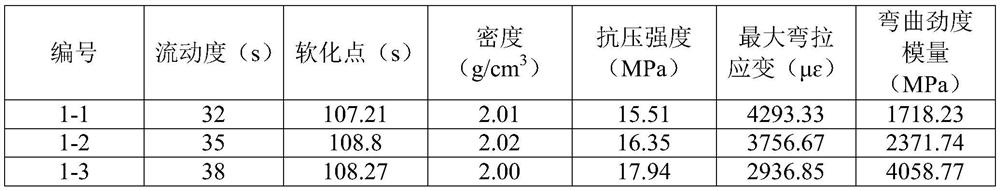

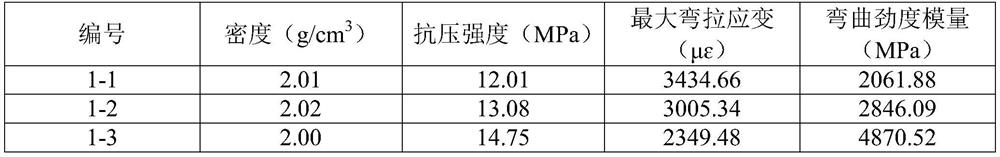

[0029] 1) Weigh each raw material in the following proportions: 14% of binder, 45% of filler, 8% of pigment, 23% of reflective glass beads, 1% of plasticizer (No. 1-1), 2% (No. 1- 2), 3% (No. 1-3), elasticizer 8%, rheology agent 2%, warm mix agent 2%, light shielding agent 1%;

[0030] 2) Dry-mix the binder, fillers, pigments, reflective materials, plasticizers, elasticizers, warm-mixing agents and light-shielding agents evenly, and heat at 160°C for 15 minutes. When the coating is initially melted, add rheology agent and mix quickly and evenly , adjust the melt fluidity of the coating to be less than 45s (mixing time is about 5min), and obtain a high-altitude cooling high-performance road hot-melt marking coating, which can be directly coated on the road.

[0031] The performance test results of the high-altitude cooling type...

Embodiment 2

[0038] A preparation method of a cooling type high-performance road hot-melt marking paint in high-altitude areas, the specific steps are as follows:

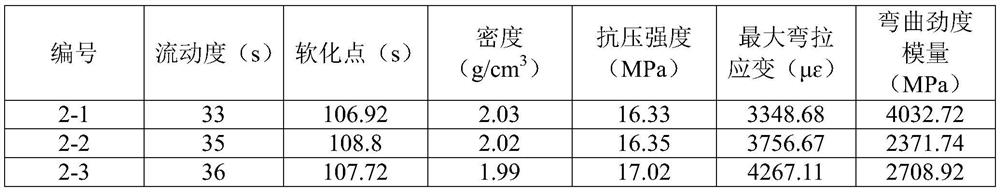

[0039] 1) Weigh each raw material in proportion: binder 14%, filler 45%, pigment 8%, reflective material 23%, plasticizer 2%, elasticizer 6% (No. 2-1), 8% (No. 2) -2), 10% (No. 2-3), 2% rheology agent, 2% warm mix agent, 1% light shielding agent;

[0040] 2) Dry-mix the binder, fillers, pigments, reflective materials, plasticizers, elasticizers, warm-mixing agents and light-shielding agents evenly, and heat at 160°C for 15 minutes. When the coating is initially melted, add rheology agent and mix quickly and evenly , adjusting the melt fluidity of the paint to be less than 45s, and obtaining a cooling type high-performance road hot-melt marking paint in high-altitude areas, which can be directly coated on the road.

[0041]The performance test results of the high-altitude cooling type high-performance road hot-melt marking pain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com