A kind of water-based acrylic elastic emulsion and its preparation method and its application on asphalt pavement

A water-based acrylic and elastic emulsion technology, applied in the chemical industry, can solve the problem of cracks easily formed on asphalt pavement, and achieve the effects of not easy demulsification, lowering glass transition temperature and stable storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

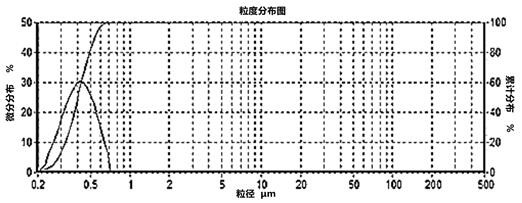

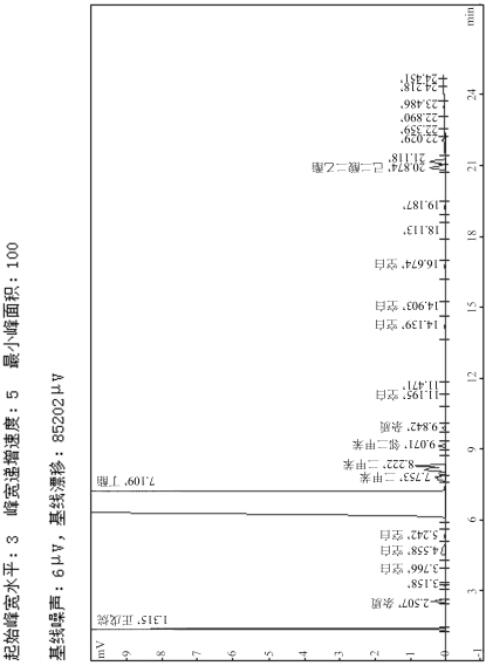

Image

Examples

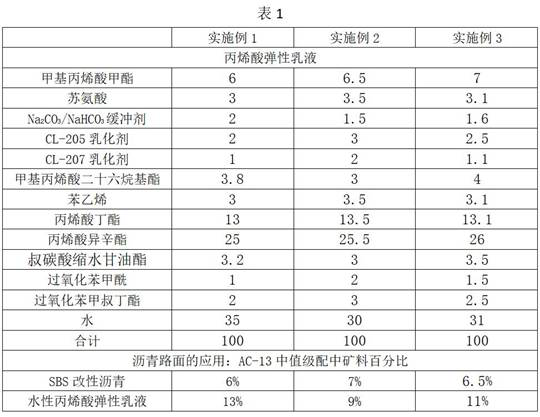

Embodiment 1

[0030] A preparation method of water-based acrylic elastic emulsion, adding raw materials according to the following parts by weight and preparing according to the following steps:

[0031] Step 1. Preparation of acrylic acid seed emulsion: 6 parts of water-soluble monomer methyl methacrylate and 3 parts of threonine were mixed and stirred at 150r / min for 5 minutes, and then Na 2 CO 3 / NaHCO 3 0.5 parts of PH buffer, 1 part of CL-205 nonionic emulsifier and 0.5 parts of CL-207 anionic emulsifier, stirred for 10 minutes, and finally added 3.8 parts of oily monomer hexadecyl methacrylate, 3 parts of styrene 13 parts of butyl acrylate, 25 parts of isooctyl acrylate, and 3.2 parts of glycidyl tertiary carbonate, stirred at 300r / min for 30min to obtain acrylic seed emulsion, which was divided into two parts, the first part of the seed emulsion The ratio with the second part of the seed emulsion is 1: 2;

[0032] Step 2, preparation of acrylic acid pre-emulsion: add 0.5 parts of ...

Embodiment 2

[0035] A preparation method of water-based acrylic elastic emulsion, adding raw materials according to the following parts by weight and preparing according to the following steps:

[0036]Step 1. Preparation of acrylic acid seed emulsion: mix 6.5 parts of water-soluble monomer methyl methacrylate with 3.5 parts of threonine, stir at 200r / min for 3min, then add Na 2 CO 3 / NaHCO 3 0.3 parts of PH buffer, 1.5 parts of CL-205 nonionic emulsifier and 1 part of CL-207 anionic emulsifier, stirred for 5 minutes, and finally added 3 parts of oily monomer hexadecyl methacrylate, 3.5 parts of styrene 13.5 parts of butyl acrylate, 25.5 parts of isooctyl acrylate, and 3 parts of glycidyl tertiary carbonate, stirred at 250r / min for 45 minutes to obtain acrylic acid seed emulsion. The seed emulsion was divided into two parts, the first part of the seed emulsion The ratio with the second part of the seed emulsion is 1.5: 2;

[0037] Step 2. Preparation of acrylic acid pre-emulsion: Add 1 ...

Embodiment 3

[0040] A preparation method of water-based acrylic elastic emulsion, adding raw materials according to the following parts by weight and preparing according to the following steps:

[0041] Step 1. Preparation of acrylic acid seed emulsion: mix 7 parts of water-soluble monomer methyl methacrylate with 3.1 parts of threonine, stir at 180r / min for 4min, then add Na 2 CO 3 / NaHCO 3 0.35 parts of PH buffer, 1.25 parts of CL-205 nonionic emulsifier and 0.55 parts of CL-207 anionic emulsifier, stirred for 8 minutes, and finally added 4 parts of oily monomer hexadecyl methacrylate, 3.1 parts of styrene part, 13.1 parts of butyl acrylate, 26 parts of isooctyl acrylate, and 3.5 parts of glycidyl tertiary carbonate, stirred at 280r / min for 40min to obtain an acrylic seed emulsion. The seed emulsion was divided into two parts, the first part of the seed emulsion The ratio with the second part of the seed emulsion is 1.25: 2;

[0042] Step 2. Preparation of acrylic acid pre-emulsion: A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com