PPR pipe material resistant to low-temperature cracking, preparation method thereof and PPR pipe product prepared from PPR pipe material

A low-temperature-resistant, high-quality product technology, which is applied in the processing field of PPR pipes, can solve the problems of low-temperature shock contribution, failure to meet the anti-cracking requirements of low-temperature environments, and cracking of PPR pipes, so as to improve brittleness, enhance crystal structure stability, Effect of reducing intermolecular tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0051] Embodiments 1-5 provide a PPR pipe material, the contents of each component are shown in Table 1, and the preparation method follows the following steps:

[0052] Mix PPR, PPB, LLDPE, color masterbatch, and β-nucleating agent evenly to obtain a low-temperature cracking-resistant PPR pipe material.

[0053] The component content (weight part) of table 1 embodiment 1~5PPR pipe material

[0054] 1 2 3 4 5 PPR 100 100 100 100 100 PPB 10 15 20 10 10 β nucleating agent 0.05 0.05 0.05 0.1 0.05 LLDPE 5 5 5 5 3 Masterbatch 5 5 5 5 5

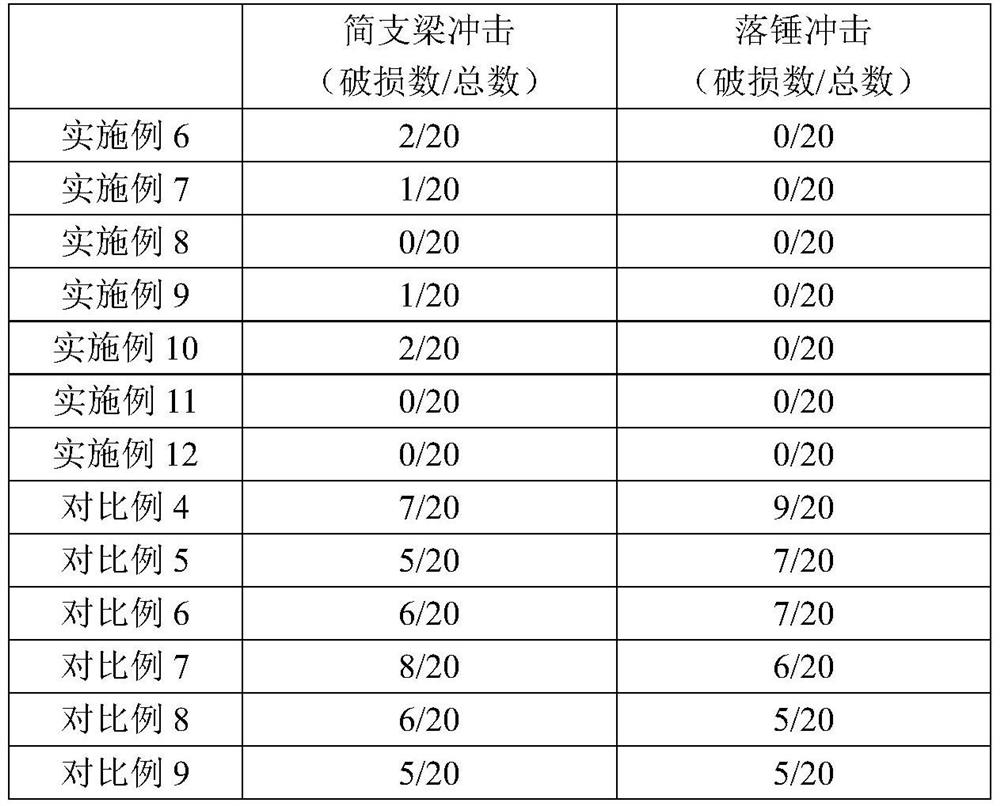

Embodiment 6~10

[0056] Examples 6-10 are PPR pipes prepared by using the pipe materials of Examples 1-5 respectively, and the preparation method follows the following steps:

[0057] S1. Extrude the low-temperature cracking-resistant PPR pipe material through a single-screw extruder to obtain a billet, and then cool and shape it to obtain a PPR pipe product to be processed;

[0058] Among them, the front section of the single-screw extruder adopts hole-type extrusion, and the total length of the die mouth of the single-screw extruder and the straight shaping section of the mandrel is 80mm;

[0059] The barrel temperature for extrusion molding is 180-210°C, the confluence core temperature is 160-180°C, and the mold temperature is 180-210°C;

[0060]Cooling and shaping is vacuum cooling, the vacuum degree during cooling is -0.02~-0.06MPa, and the cooling temperature is 15~23°C;

[0061] S2. The PPR pipe product to be treated obtained in step S1 is cured at 20° C. for 24 hours to obtain a PPR p...

Embodiment 11~12

[0063] Examples 11-12 are all PPR pipes prepared by using the pipe material of Example 1. The difference between the preparation method and Example 6 is:

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com