Hydroxylated SBS/graphene composite modified asphalt and preparation method thereof

A graphene composite and modified asphalt technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems affecting the quality and normal use of asphalt, the deterioration of asphalt performance, and the reduction of low-temperature ductility, etc., to achieve good storage stability High stability, high ductility, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

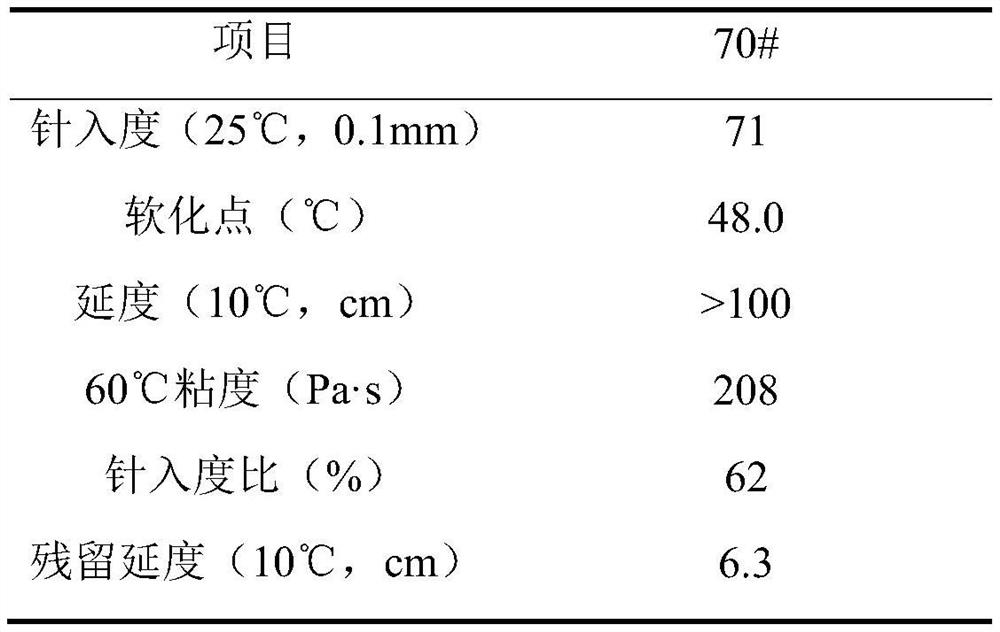

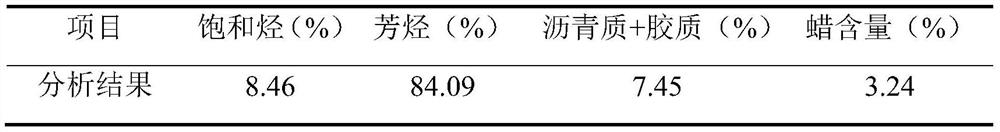

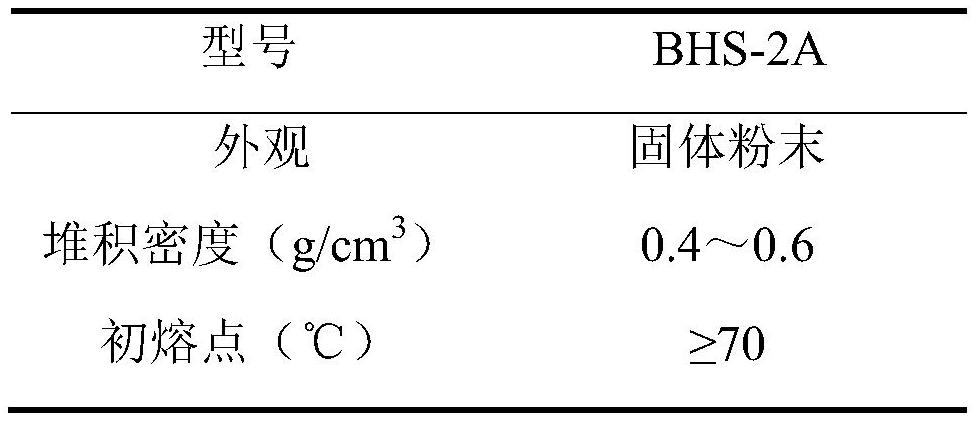

[0069] Ingredients: The mass percentages of each component are: base asphalt 94.4%, SBS-OH 4.3%; graphene 0.1%, furfural oil 1%, BHS-2A 0.2%; the base asphalt is 70# base asphalt; linear SBS -OH has an average molecular weight of 100,000.

[0070] Take 70# base asphalt and heat it to 185±5°C to melt; then add furfural to extract oil and SBS-OH, stir and premix at 200r / min for 1h, and shear at 175±5°C for 25min at high speed, with a shear rate of 2500r / min ; Add graphene, shear for 20 minutes, and the shear rate is 2500r / min; after adding the stabilizer (BHS-2A), continue high-speed shearing for 10 minutes, and then develop at 175±5°C for 4.5 hours at a stirring rate of 100r / min. The modified asphalt was obtained (see Table 4 for properties).

Embodiment 2

[0078] Ingredients: The mass percentages of each component are: base asphalt 94.3%, SBS-OH 4.3%; graphene 0.2%, furfural oil 1%, BHS-2A 0.2%; the base asphalt is 70# base asphalt; linear SBS -OH has an average molecular weight of 100,000.

[0079] Take 70# base asphalt and heat it to 185±5°C to melt; then add furfural to extract oil and SBS-OH, stir and premix at 200r / min for 1h, and shear at 175±5°C for 25min at high speed, with a shear rate of 2500r / min ; Add graphene, shear for 20 minutes, and the shear rate is 2500r / min; after adding the stabilizer (BHS-2A), continue high-speed shearing for 10 minutes, and then develop at 175±5°C for 4.5 hours at a stirring rate of 100r / min. The modified asphalt was obtained (see Table 4 for properties).

Embodiment 3

[0081] Ingredients: The mass percentages of each component are: base asphalt 94.2%, SBS-OH 4.3%; graphene 0.3%, furfural oil 1%, BHS-2A 0.2%; the base asphalt is 70# base asphalt; linear SBS -OH has an average molecular weight of 100,000.

[0082] Take 70# base asphalt, heat it to 185±5℃ to melt; then add furfural extract oil and SBS-OH, stir and premix at 200r / min for 1h, and shear at 175±5℃ for 25min at a high speed, with a shear rate of 2500r / min min; add graphene, shear 20min, shear rate 2500r / min; add stabilizer (BHS-2A), continue high-speed shearing for 10min, then develop at 175±5°C, stirring rate 100r / min for 4.5h , to obtain modified asphalt (properties are shown in Table 4).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com