Biological asphalt material for roads and preparation method of biological asphalt material

A bio-asphalt and road technology, applied in building insulation materials, building structures, building components, etc., can solve problems such as low strength and poor stability, achieve good stability, effective recycling, improve water stability and low temperature resistance The effect of cracking properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

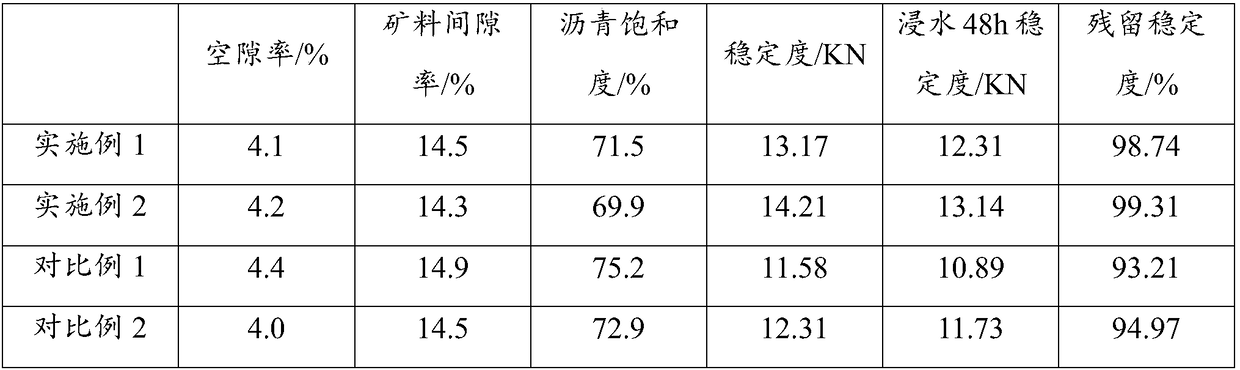

Examples

Embodiment 1

[0021] Step 1: Weigh the following raw materials in parts by weight: 28 parts of base asphalt, 15 parts of waste polymer material powder, 0.1 part of zinc oxide, 15 parts of diluent, 2 parts of leveling agent MS, 0.2 parts of stabilizer sulfur, and 0.05 parts of graphene powder parts, 0.05 parts of carbon nanotubes.

[0022] Step 2: Pyrolyzing the waste polymer material powder into bio-oil, distilling the bio-oil at atmospheric pressure, and collecting heavy components of bio-oil above 100°C.

[0023] Step 3: Heat the base asphalt to 150°C and stir for 3 minutes, then cool down to 110°C, continue stirring for 3 minutes, then raise the temperature to 170°C, and stir for 30 minutes at a stirring rate of 2000r / min to obtain a premix.

[0024] Step 4: Cool the premix to 110°C, then add 0.1 part of zinc oxide, diluent, homogenizer MS, stabilizer sulfur, and continue stirring for 7 minutes at a stirring rate of 2000r / min;

[0025] Step 5: Add graphene powder and carbon nanotubes, a...

Embodiment 2

[0027] Step 1: Weigh the following raw materials in parts by weight: 25 parts of matrix asphalt, 11 parts of waste polymer material powder, 0.12 parts of zinc oxide, 13 parts of thinner, 1 part of homogenizer MS, 0.2 parts of stabilizer sulfur, and 0.1 part of graphene powder parts, 0.05 parts of carbon nanotubes.

[0028] Step 2: Pyrolyzing the waste polymer material powder into bio-oil, distilling the bio-oil at atmospheric pressure, and collecting heavy components of bio-oil greater than 100°C;

[0029] Step 3: Heat the base asphalt to 140°C and stir for 3 minutes, then cool down to 105°C, continue stirring for 2 minutes, then raise the temperature to 180°C, and stir for 30 minutes at a stirring rate of 1500r / min to obtain a premix.

[0030] Step 4: Cool the premixed material to 120°C, then add bio-oil heavy component, zinc oxide, diluent, homogenizer MS, stabilizer sulfur, and continue to stir for 7 minutes at a stirring rate of 1500r / min;

[0031] Step 5: Add graphene po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com