High-ductility modified asphalt and preparation method thereof

A technology for modifying asphalt and ductility, which is applied in building components, building insulation materials, buildings, etc., and can solve problems such as ineffective improvement of low-temperature ductility, damage to molecular chain structure, and impact on SBS performance, and achieve good storage stability , Expand the scope of application, the effect of high crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

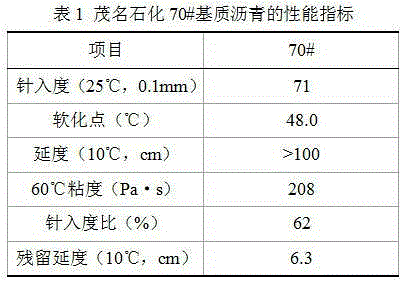

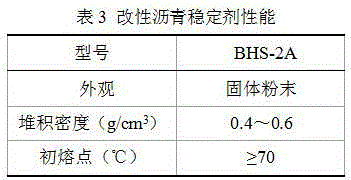

[0040] Ingredients: The mass percentages of each component are: base asphalt 94.5%, SBS-OH 4.3%; furfural oil 1%, BHS-2A 0.2%; base asphalt is 70# base asphalt; linear SBS-OH The average molecular weight is 80,000.

[0041] Take 70# base asphalt and heat it to 185±5°C to melt; then add furfural to extract oil and SBS-OH, stir and premix at 200r / min for 1h, and shear at 175±5°C for 25min at high speed, with a shear rate of 2500r / min ; After adding stabilizer (BHS-2A), continue high-speed shearing for 10 minutes, and then develop at 175±5°C for 4.5 hours at a stirring rate of 100r / min to obtain modified asphalt (see Table 4 for properties).

Embodiment 2

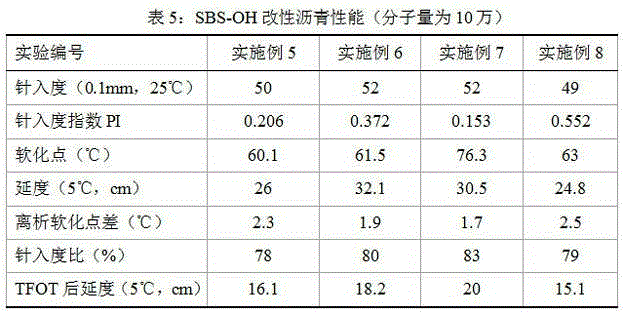

[0046] Ingredients: The mass percentages of each component are: base asphalt 94.5%, SBS-OH 4.3%; furfural oil 1%, BHT-2A 0.2%; base asphalt is 70# base asphalt; linear SBS-OH The average molecular weight is 100,000.

[0047] Take 70# base asphalt and heat it to 185±5°C to melt; then add furfural to extract oil and SBS-OH, stir and premix at 200r / min for 1h, and shear at 175±5°C for 25min at high speed, with a shear rate of 2500r / min ; After adding stabilizer (BHS-2A), continue high-speed shearing for 10 minutes, and then develop at 175±5°C for 4.5 hours at a stirring rate of 100r / min to obtain modified asphalt (see Table 4 for properties).

Embodiment 3

[0052] Ingredients: The mass percentages of each component are: base asphalt 94.5%, SBS-OH 4.3%; furfural oil 1%, BHT-2A 0.2%; base asphalt is 70# base asphalt; linear SBS-OH The average molecular weight is 120,000.

[0053] Take 70# base asphalt, heat it to 185±5℃ to melt; then add furfural extract oil and SBS-OH, stir and premix at 200r / min for 1h, and shear at 175±5℃ for 25min at a high speed, with a shear rate of 2500r / min min; After adding the stabilizer (BHS-2A), continue high-speed shearing for 10 min, and then develop at 175±5°C for 4.5 h at a stirring rate of 100 r / min to obtain modified asphalt (see Table 4 for properties).

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com