Laser-arc hybrid welding method

A hybrid welding and laser arc technology, which is applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of slow welding speed, etc., and achieve the effect of improving low-temperature crack resistance and reducing the amount of diffusible hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Regarding the amount of diffusible hydrogen in the weld metal portion of the hybrid laser arc welded joint, the present invention will be described more specifically with examples given.

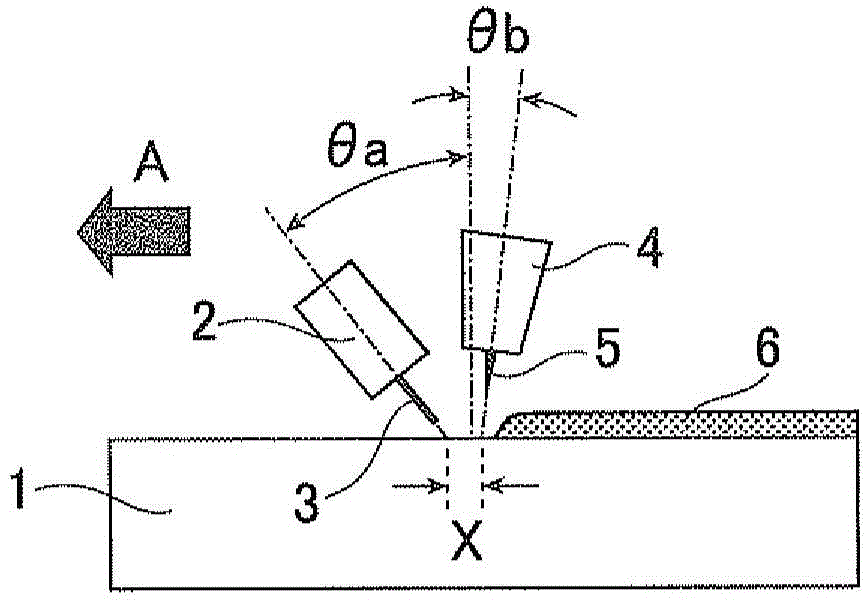

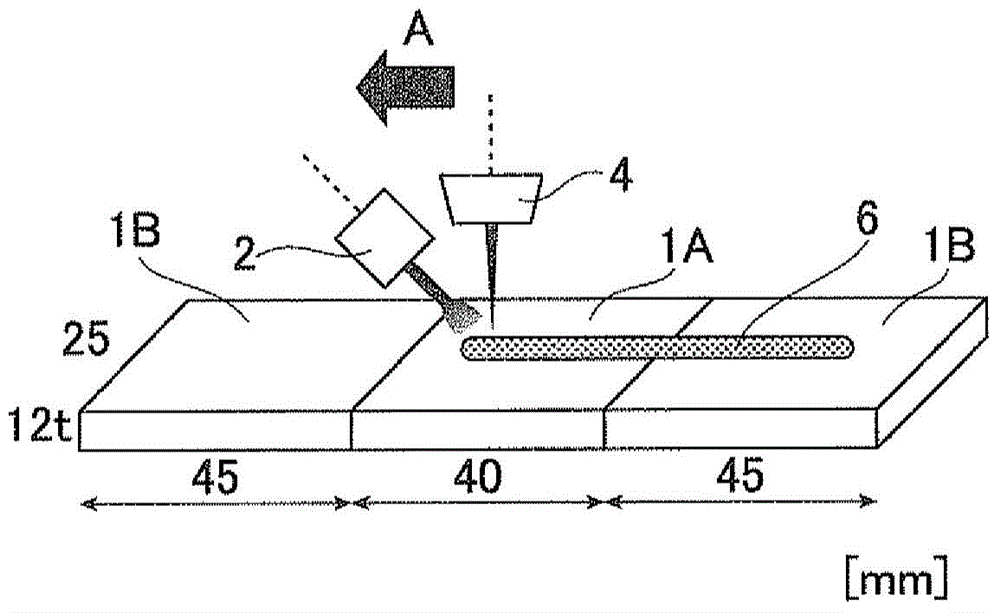

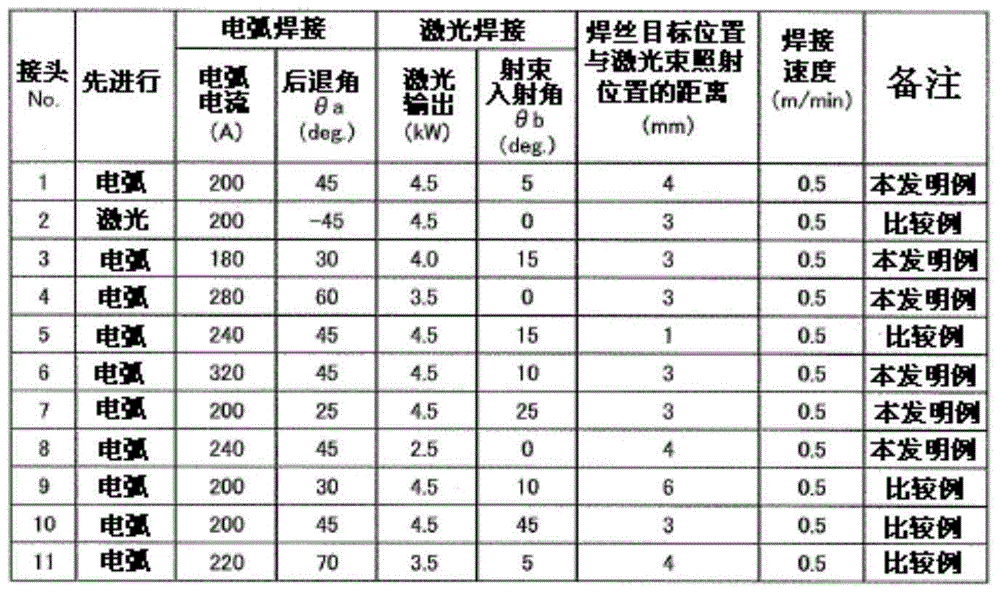

[0044] As a method of measuring the amount of hydrogen in a steel welded portion targeted for arc welding, the test method described in JIS Z 3118 is generally used. Therefore, in the measurement of diffusible hydrogen in hybrid laser arc welding, basic items such as the shape of the test piece, the capture of diffusible hydrogen, and the method of measuring the amount of hydrogen are carried out in accordance with JIS (Japanese Industrial Standards). That is, from the HT780 grade steel plate used as the test steel, a figure 2 Test plate 1A with plate thickness 12mm x width 25mm x length 40mm as shown and arc starting plate (end tab) 1B with plate thickness 12mm x width 25mm x length 45mm were measured for various laser arc hybrid welding conditions. The amount of diffusible hydroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com