Cement-based conductive composite material and preparation method thereof

A conductive composite material, cement-based technology, applied in the field of cement materials, can solve problems such as poor electromagnetic wave absorption function, and achieve the effects of good electromagnetic wave absorption effect, improved fluidity, and strong electromagnetic wave absorption function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

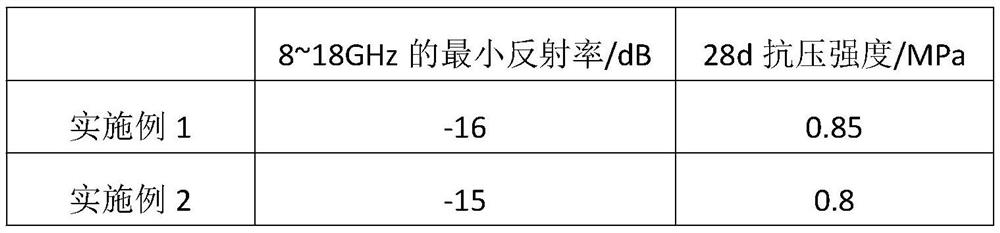

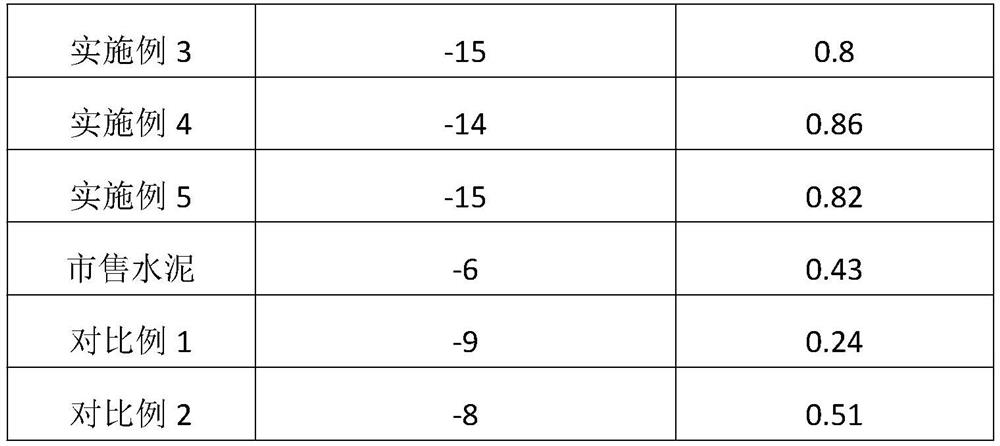

Examples

Embodiment 1

[0060] Weigh the following raw materials in parts by weight:

[0061] 80 parts of cement;

[0062] 120 parts of fly ash;

[0063] 85 parts of silica fume;

[0064] 85 parts of water;

[0065] 2 parts of DH-4004 water reducer;

[0066] 10 parts of rubber powder;

[0067] 5 parts of steel fiber;

[0068] 2 parts of carbon fiber;

[0069] 2 parts polyvinyl alcohol fiber;

[0070] Ferrite 45 parts.

[0071] Wherein, cement comprises the raw material of following parts by weight: 20.5 parts of SiO 2 , 3.2 parts of Fe 2 o 3 , 5.1 parts Al 2 o 3 , 62.5 parts of CaO, 1.05 parts of MgO, 2 parts of SO 3 , 0.65 K 2 O.

[0072] Fly ash comprises the raw material of following parts by weight: 52.5 parts of SiO 2 , 5.6 parts of Fe 2 o 3 , 30.6 parts Al 2 o 3 , 3.9 parts of CaO, 1.2 parts of MgO, 1.5 parts of SO 3 , 1.5 copies of K 2 O.

[0073] Silica fume comprises the following raw materials in parts by weight: 94.5 parts of SiO 2 , 0.76 Fe 2 o 3 , 0.25 parts of ...

Embodiment 2

[0085] Weigh the following raw materials in parts by weight:

[0086] 100 parts of cement;

[0087] 110 parts of fly ash;

[0088] 80 parts of silica fume;

[0089] 120 parts of water;

[0090] 3 parts of DH-4004 water reducer;

[0091] 12 parts of rubber powder;

[0092] 2 parts of steel fiber;

[0093] 3 parts of carbon fiber;

[0094] 1 part polyvinyl alcohol fiber;

[0095] 30 parts of ferrite.

[0096] Wherein, cement comprises the raw material of following parts by weight: 20.8 parts of SiO 2 , 3.3 parts of Fe 2 o 3 , 5.5 parts Al 2 o 3 , 63.5 parts of CaO, 1.1 parts of MgO, 2.1 parts of SO 3 , 0.67 K 2 O.

[0097] Fly ash comprises the raw material of following parts by weight: 53 parts of SiO 2 , 5.8 parts Fe 2 o 3 , 31 Al 2 o 3 , 4.1 parts of CaO, 1.3 parts of MgO, 1.6 parts of SO 3 , 1.6 K 2 O.

[0098] Silica fume comprises the following raw materials in parts by weight: 95 parts of SiO 2 , 0.8 parts of Fe 2 o 3 , 0.26 parts of Al 2 o 3 ,...

Embodiment 3

[0110] Weigh the following raw materials in parts by weight:

[0111] 90 parts of cement;

[0112] 140 parts of fly ash;

[0113] 90 parts of silica fume;

[0114] 70 parts of water;

[0115] 1 part of DH-4004 type water reducer;

[0116] 15 parts of rubber powder;

[0117] 2 parts of steel fiber;

[0118] 1 carbon fiber;

[0119] 1 part polyvinyl alcohol fiber;

[0120] 50 parts of ferrite.

[0121] Wherein, cement comprises the raw material of following parts by weight: 21.2 parts of SiO 2 , 3.5 parts of Fe 2 o 3 , 5.8 parts Al 2 o 3 , 65 parts of CaO, 1.3 parts of MgO, 2.3 parts of SO 3 , 0.7 K 2 O.

[0122] Fly ash comprises the raw material of following parts by weight: 54 parts of SiO 2 , 6 Fe 2 o 3 , 31.5 parts Al 2 o 3 , 4.3 parts of CaO, 1.5 parts of MgO, 1.65 parts of SO 3 , 1.65 K 2 O.

[0123] Silica fume comprises the following raw materials in parts by weight: 95.5 parts of SiO 2 , 0.82 Fe 2 o 3 , 0.27 parts of Al 2 o 3 , 0.55 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com