High-entropy MAX-phase wave-absorbing material and preparation method thereof

A mutual-attraction, high-entropy technology, applied in antennas, electrical components, magnetic/electric field shielding, etc., to achieve the effects of low production cost, strong wave-absorbing ability, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0042] In yet another specific embodiment of the present invention, a method for preparing the above-mentioned high-entropy MAX phase wave absorbing material is provided, the method comprising:

[0043] S1. Determine the required amount of powder containing each element according to the stoichiometric ratio of each element in the nominal chemical formula of the high-entropy MAX phase wave absorbing material, and the powder includes M elemental powder, A elemental powder and carbon powder;

[0044] S2, mixing the M elemental powder and the carbon powder in step S1 and sintering;

[0045] S3. The sintered product obtained in step S2 is mixed with A elemental powder and then sintered.

[0046] Wherein, in the step S1,

[0047] M elemental powder is at least four element elemental powders selected from IIIB, IVB, VB and VIB group elements;

[0048] A elemental powder is at least one element elemental powder selected from IIIA, IVA, VA and VIA group elements;

[0049] The molar ra...

Example Embodiment

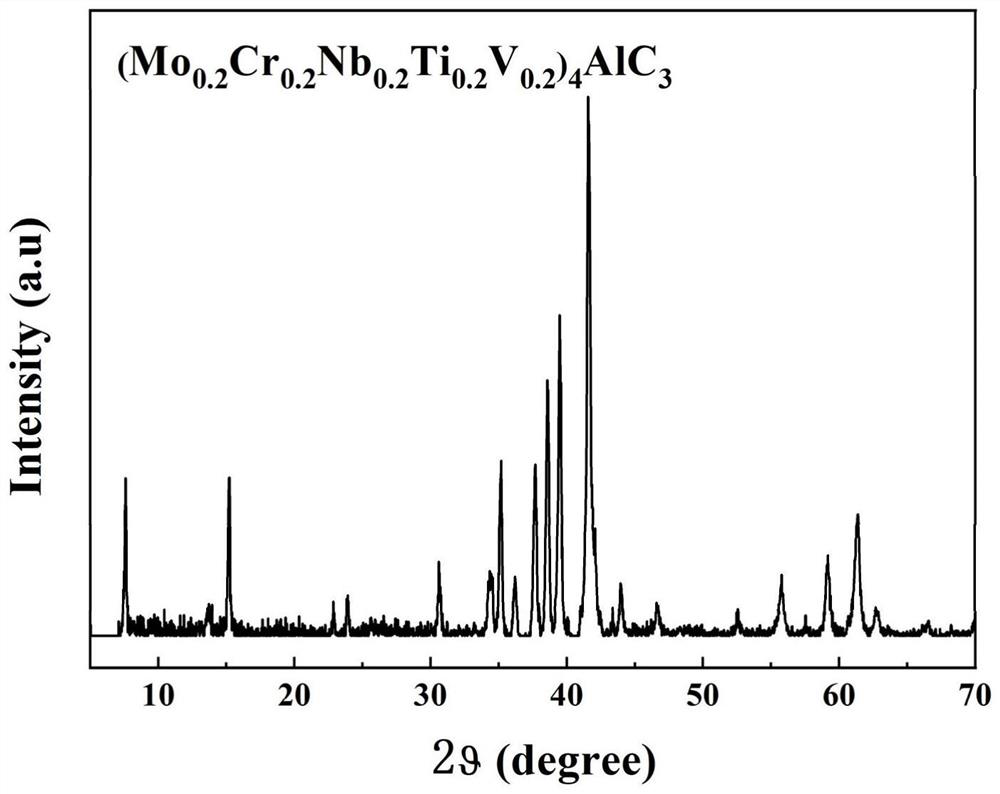

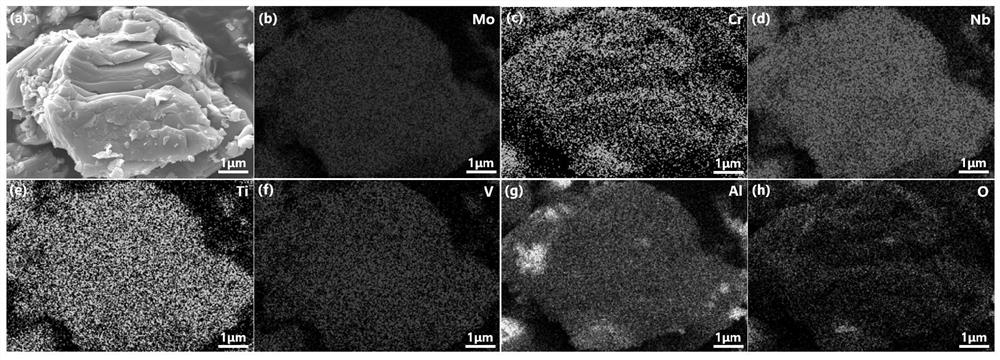

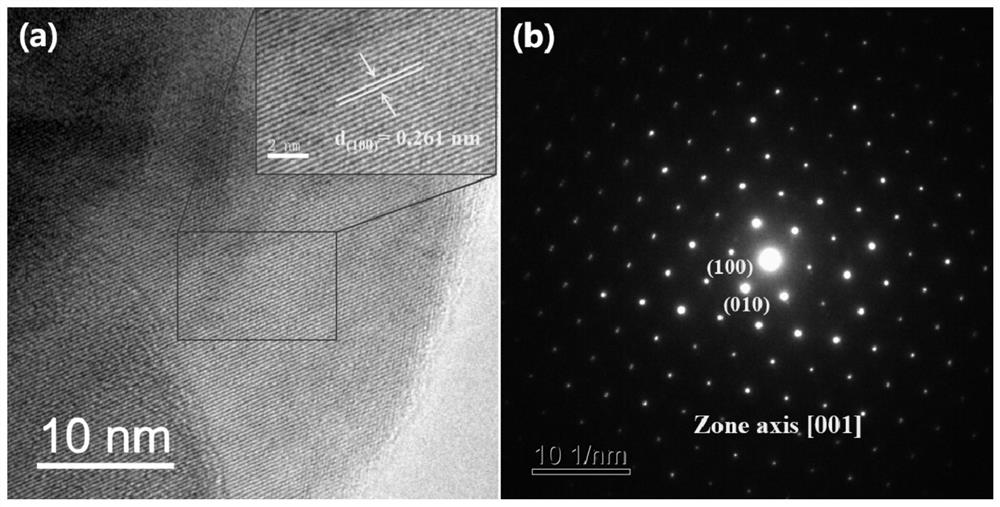

[0062] Example 1:

[0063] In this example, a high-entropy MAX phase absorbing material was prepared. The specific steps are as follows:

[0064] 1) Prepare powder according to the molar ratio Mo:Cr:Nb:Ti:V:Al:C=0.8:0.8:0.8:0.8:0.8:1.9:2.5;

[0065] 2) grinding and mixing M elemental powder and carbon powder in step 1);

[0066] 3) The mixed powder obtained in step 2) is placed in a corundum crucible, and under Ar atmosphere conditions, the temperature rises at a rate of 5°C / min to 1600°C, and after holding for 3 hours, it is cooled with the furnace;

[0067] 4) grinding and mixing the sintered product in step 3) with A elemental powder;

[0068] 5) Transfer the mixed powder obtained in step 4) to a corundum crucible, and under Ar atmosphere conditions, the temperature rise rate is 5°C / min and the temperature is raised to 1400°C, after holding for 1 hour, it is cooled with the furnace, and the loose block obtained after cooling is taken out. Grinding to obtain the high-ent...

Example Embodiment

[0071] Example 2:

[0072] In this example, a high-entropy MAX phase absorbing material was prepared. The specific steps are as follows:

[0073] 1) Prepare the powder according to the molar ratio Mo:Cr:Ti:V:Al:C=1:1:1:1:2:2.1;

[0074] 2) grinding and mixing M elemental powder and carbon powder in step 1);

[0075] 3) The mixed powder obtained in step 2) is placed in a corundum crucible, and under Ar atmosphere, the temperature rises at a rate of 5°C / min to 1650°C, and after holding for 2 hours, it is cooled with the furnace;

[0076] 4) grinding and mixing the sintered product in step 3) with A elemental powder;

[0077] 5) Transfer the mixed powder obtained in step 4) into a corundum crucible, and under Ar atmosphere conditions, the temperature rise rate is 5°C / min and the temperature is raised to 1500°C, after holding for 1 h, it is cooled with the furnace, and the loose block obtained after cooling is taken out. Grinding to obtain the high-entropy MAX phase (Mo 0.25 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Return loss | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com