Method for microwave treatment of red-layer roadbed filler

A roadbed filler and microwave treatment technology, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of being easily affected by weather conditions, not considering the processing time, endangering life safety, etc., achieving fast heating speed, reducing processing time, The effect of reducing the frequency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

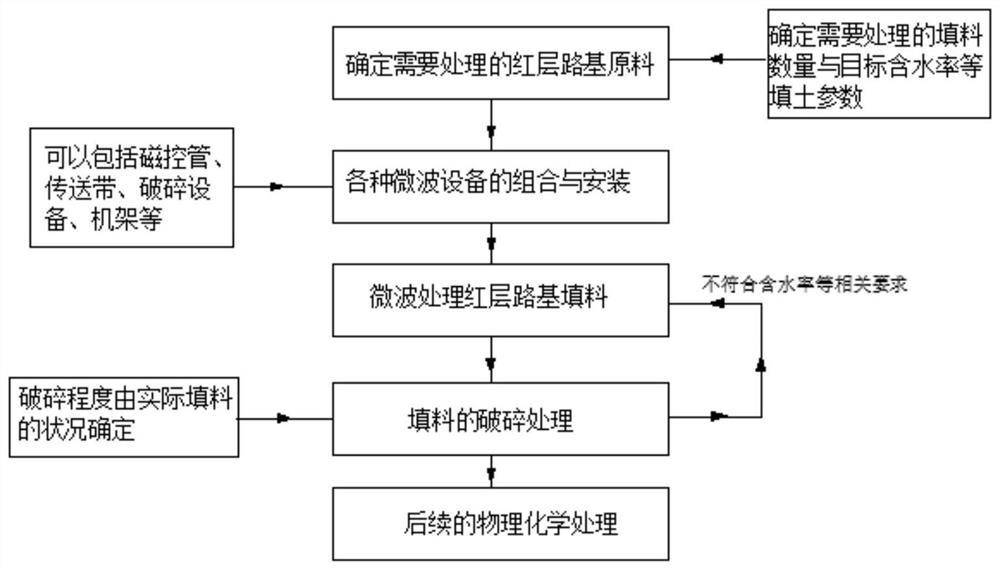

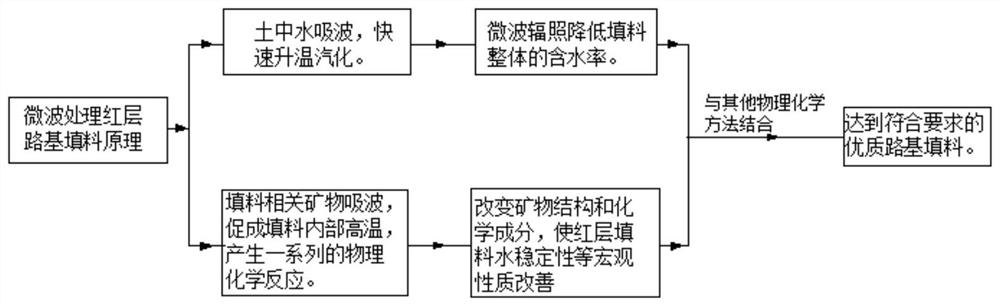

Method used

Image

Examples

Embodiment Construction

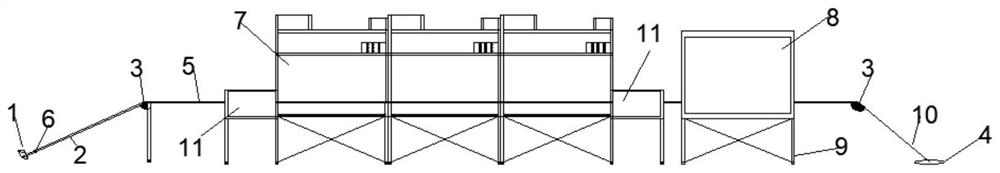

[0035] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments of the present invention, and the described embodiments are only a part of the embodiments of the present invention, rather than all embodiments.

[0036] As shown in the figure, a microwave treatment device and method for roadbed filler of the present invention includes a filler input port 1; a conveyor belt side baffle 2; a conveyor belt rotating motor 3; a roadbed filler 4; a non-absorbing conveyor belt 5; Board 6; microwave equipment box 7; crushing equipment 8; bearing frame 9; filler output port 10; microwave suppressor 11 and other main equipment.

[0037] Such as Figure 5 As shown, the filler input port 1 of the present invention is the beginning of the material entering the conveyor belt; the material of the conveyor belt is required to be a non-absorbing material, and the side baffles 2 of the conveyor belt are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com