A CNC machine tool

A technology of CNC machine tools and racks, applied in metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve the problems of reducing the speed of cutting fluid passing, reducing the quality of workpiece processing, affecting the reuse of cutting fluid, etc. Achieve the effect of speeding up heat dissipation, speeding up the drop of oil temperature and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

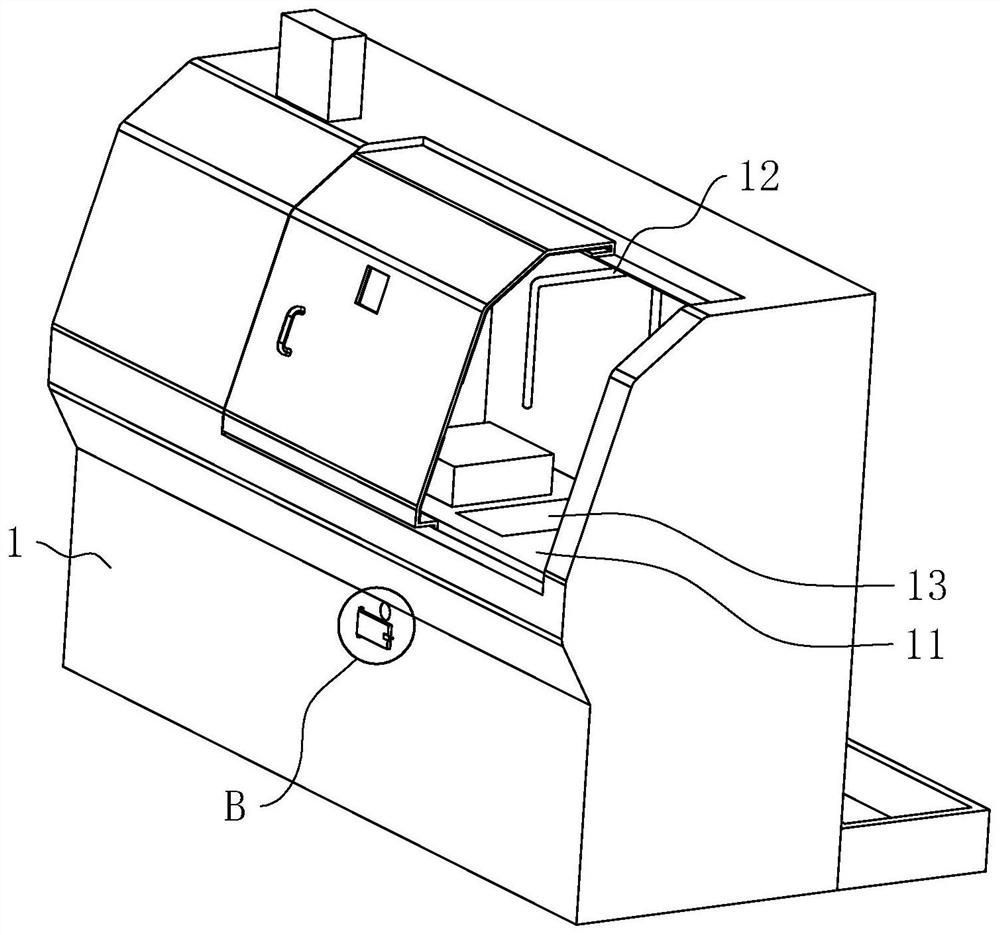

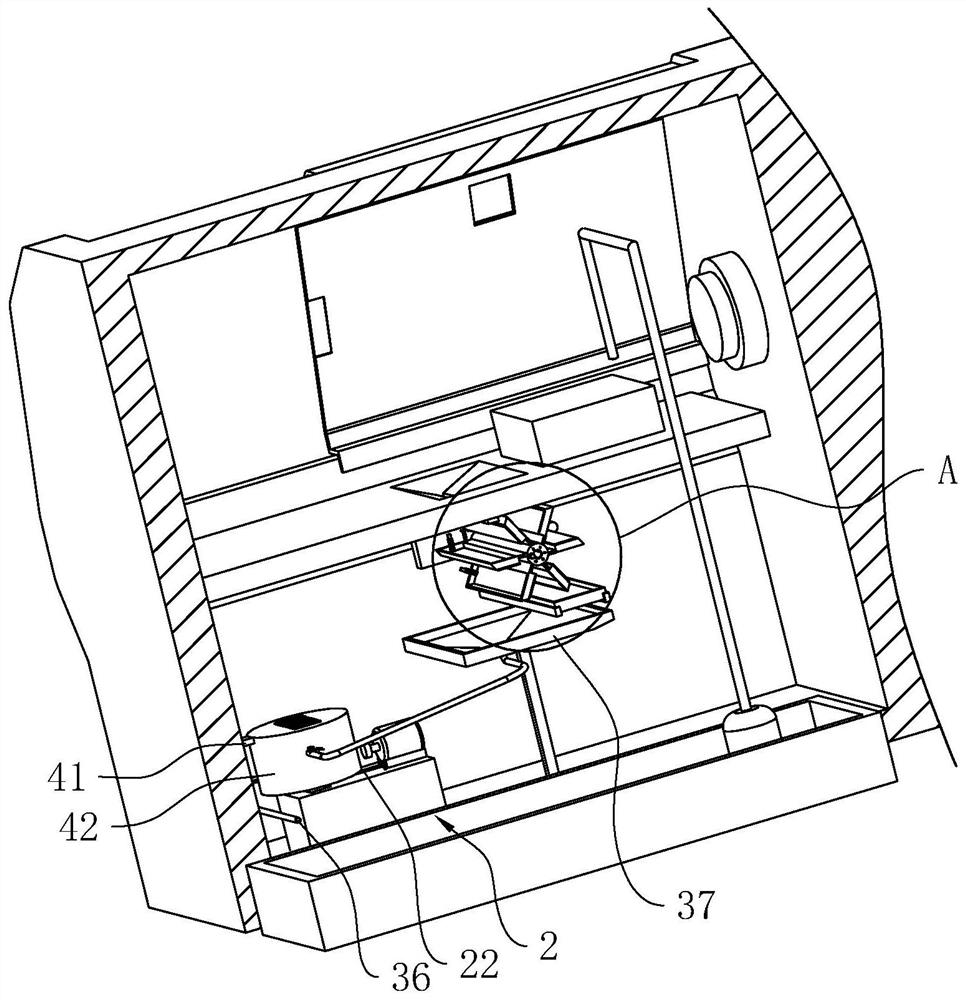

[0044] refer to figure 1 and figure 2 , a numerical control machine tool, comprising a frame 1, a workbench 11 and a cooling pipe 12 are fixedly arranged on the frame 1, a hydraulic station 2 is arranged in the frame 1 and below the workbench 11, and a liquid receiving bucket is arranged on the workbench 11 13. A collection bucket 37 is fixedly installed on the frame 1 below the liquid tray 32. The bottom of the collection bucket 37 is connected with a drain pipe 38 leading to the outside of the frame 1. After the cooling pipe 12 sprays the cutting fluid, it passes through the liquid bucket 13. Fall in the collection bucket 37, then be discharged outside the frame 1 from the collection bucket 37.

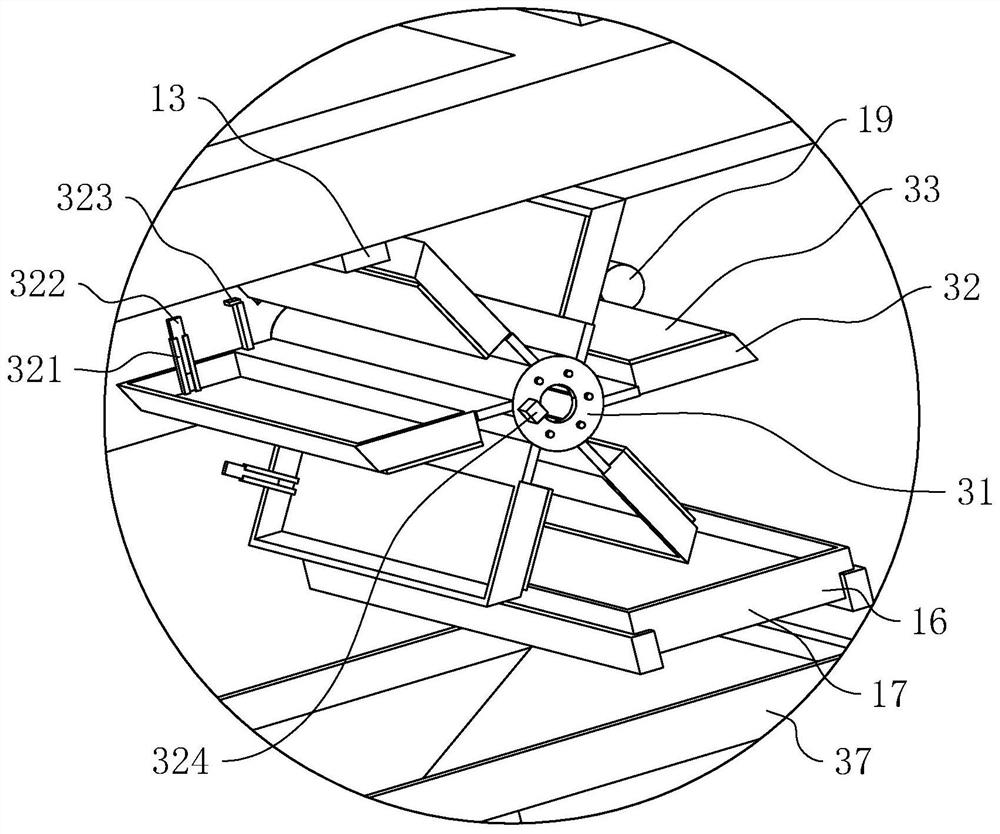

[0045] refer to figure 2 and image 3 , the lower opening of the liquid receiving bucket 13 is a flat rectangle, the frame 1 between the liquid receiving buc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com