Magnetic separation device for scrap iron

A magnetic separation device and technology of iron filings, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems that the iron filings cannot be collected cleanly, can only be cleaned manually, and the circulation pump is damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

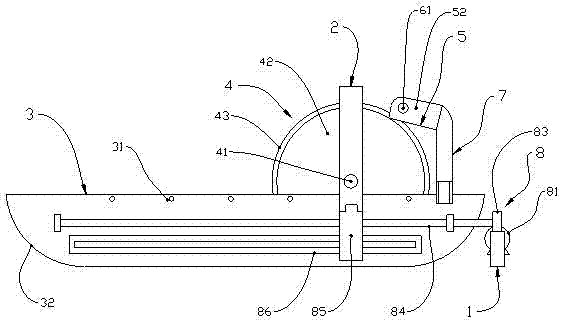

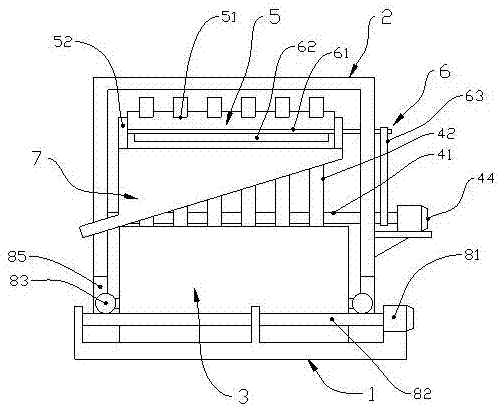

[0015] see Figure 1-2 , the present invention provides a technical solution: a magnetic separation device for iron filings, including a collection tank 3, a magnetic roller 4 and a scraper 5, the collection tank 3 is used to store the emulsion containing iron filings, and the emulsion passes through a liquid inlet pipe into the collection tank 3, the upper end of the collection tank 3 has a drain hole 31, and also includes a door-shaped support 2 across the collection tank 3 and used to drive the support 2 along the length of the collection tank 3 Direction reciprocating driving device 8, the magnetic roller 4 includes a roller shaft 41 that is rotatably supported on the bracket 2 and a plurality of roller bodies 42 that are sleeved on the roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com