A kind of one-step activation method prepares the method for electroless iron-plated graphene

An iron graphene and chemical plating technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problem of graphene being difficult to disperse evenly, and achieve the solution of difficulty in uniform dispersion, simplify the process flow, enhance the The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

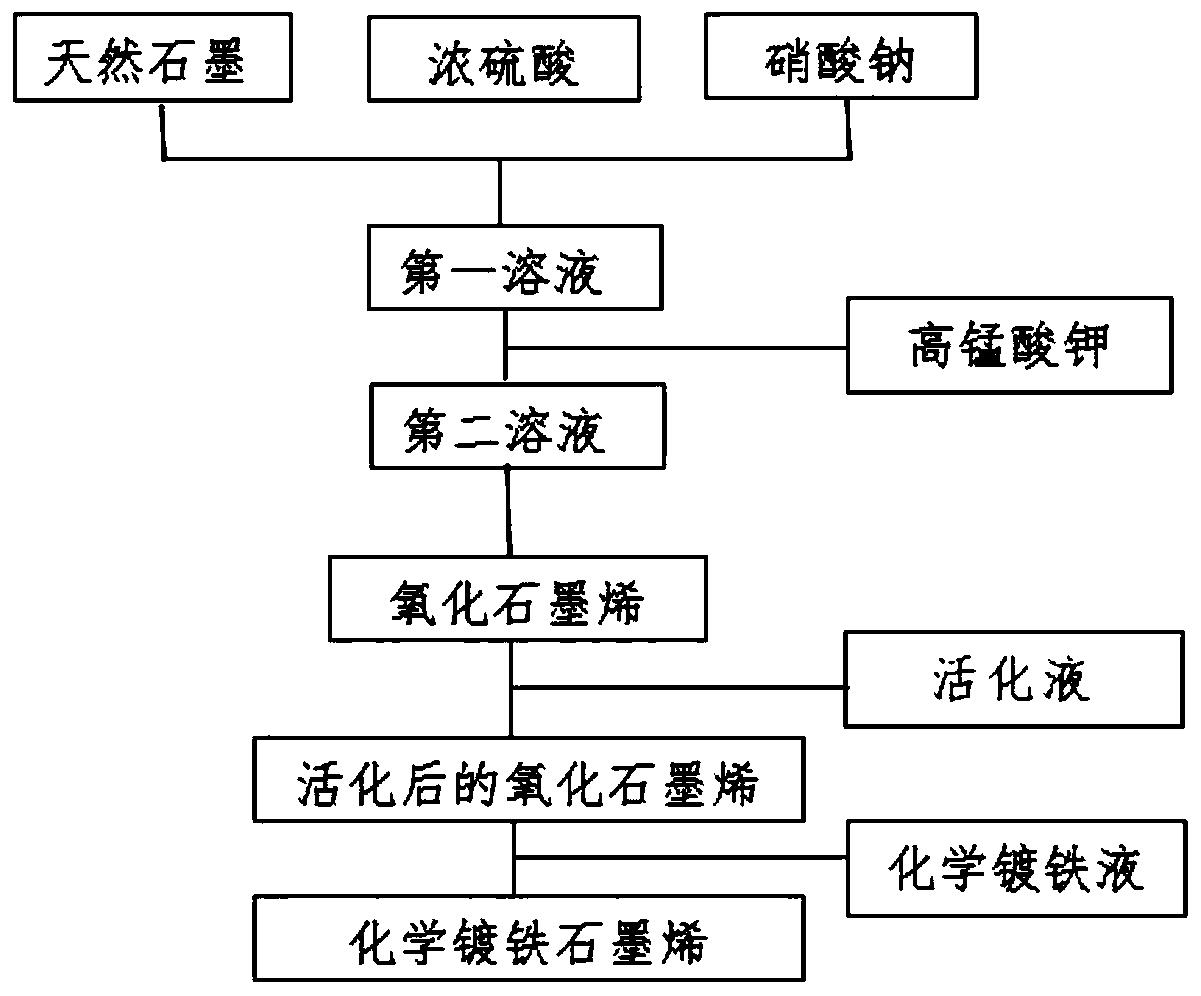

[0057] S1. Using the improved Hummers method: 1 g of natural graphite was placed in a beaker, mechanically stirred under an ice bath at 0° C., and 21 ml of concentrated sulfuric acid and 0.5 g of sodium nitrate were sequentially added to the beaker to obtain the first solution.

[0058]S2. Under mechanical stirring, slowly add 3 g of potassium permanganate to the first solution to obtain a second solution, and control the temperature of the second solution to 20° C. and keep it for 30 minutes.

[0059] S3. Raise the temperature of the second solution to 35°C and keep it for 60 minutes, then add 46ml of deionized water to the second solution, adjust the temperature of the second solution to not exceed 80°C, keep it for 15 minutes, then add 140ml of deionized water, 10ml volume fraction is 30% hydrogen peroxide, washed with 5% hydrochloric acid until the solution does not contain SO 4 2- ions, the solution was ultrasonically dispersed for 2 hours, filtered and washed twice, and...

Embodiment 2

[0066] S1. Using the improved Hummers method: 1 g of natural graphite was placed in a beaker, mechanically stirred under an ice bath at 0° C., and 21 ml of concentrated sulfuric acid and 0.8 g of sodium nitrate were sequentially added to the beaker to obtain the first solution.

[0067] S2. Under mechanical stirring, slowly add 4 g of potassium permanganate to the first solution to obtain a second solution, and control the temperature of the second solution to 20° C. and keep it for 30 minutes.

[0068] S3. Raise the temperature of the second solution to 35°C and keep it for 60 minutes, then add 50ml of deionized water to the second solution, adjust the temperature of the second solution to not exceed 80°C, keep it for 15 minutes, then add 150ml of deionized water, 10ml volume fraction is 30% hydrogen peroxide, washed with 5% hydrochloric acid until the solution does not contain SO 4 2- ions, the solution was ultrasonically dispersed for 2 hours, filtered and washed twice, an...

Embodiment 3

[0074] S1. Using the improved Hummers method: 1 g of natural graphite was placed in a beaker, mechanically stirred under an ice bath at 0° C., and 21 ml of concentrated sulfuric acid and 0.5 g of sodium nitrate were sequentially added to the beaker to obtain the first solution.

[0075] S2. Under mechanical stirring, slowly add 3 g of potassium permanganate to the first solution to obtain a second solution, and control the temperature of the second solution to 20° C. and keep it for 30 minutes.

[0076] S3. Raise the temperature of the second solution to 35°C and keep it for 60 minutes, then add 46ml of deionized water to the second solution, adjust the temperature of the second solution to not exceed 80°C, keep it for 15 minutes, then add 140ml of deionized water, 10ml volume fraction is 30% hydrogen peroxide, washed with 5% hydrochloric acid until the solution does not contain SO 4 2- ions, the solution was ultrasonically dispersed for 2 hours, filtered and washed twice, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com