Method and device for preparing tungsten powder reinforced aluminum matrix composite

A composite material, enhanced aluminum-based technology, applied in metal material coating process, melt spraying, coating and other directions, can solve the problems of long process flow, many production processes, high density of tungsten powder, etc., to achieve shortened process flow, The effect of reducing the production process and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

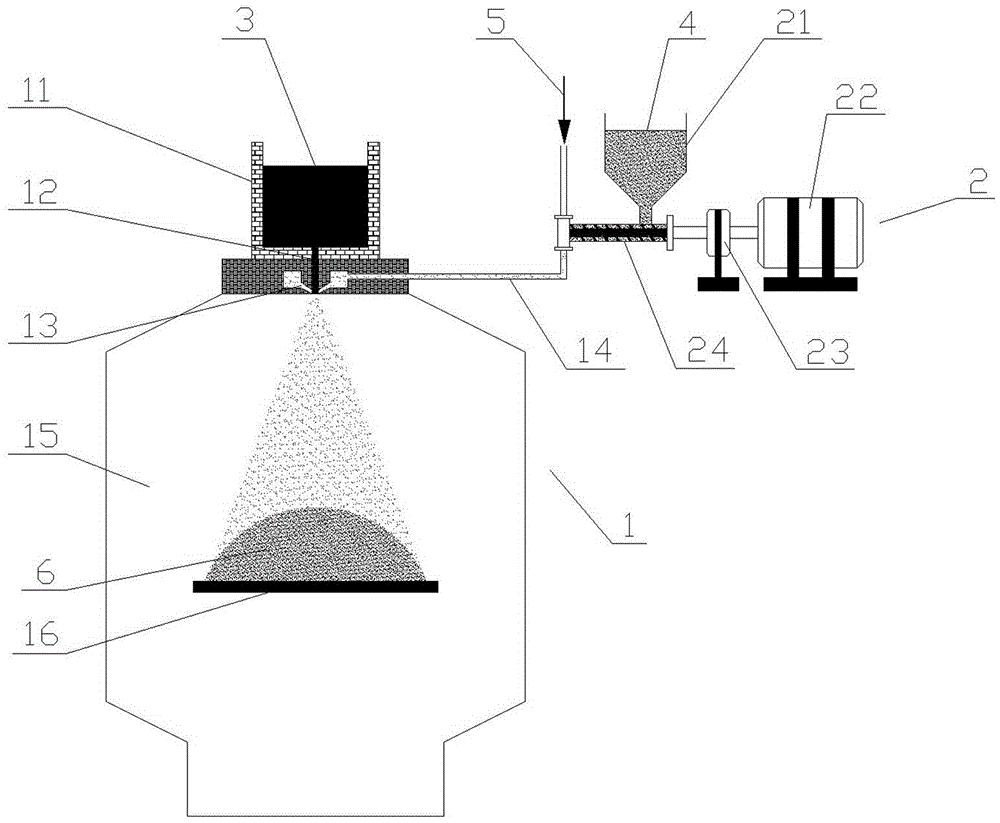

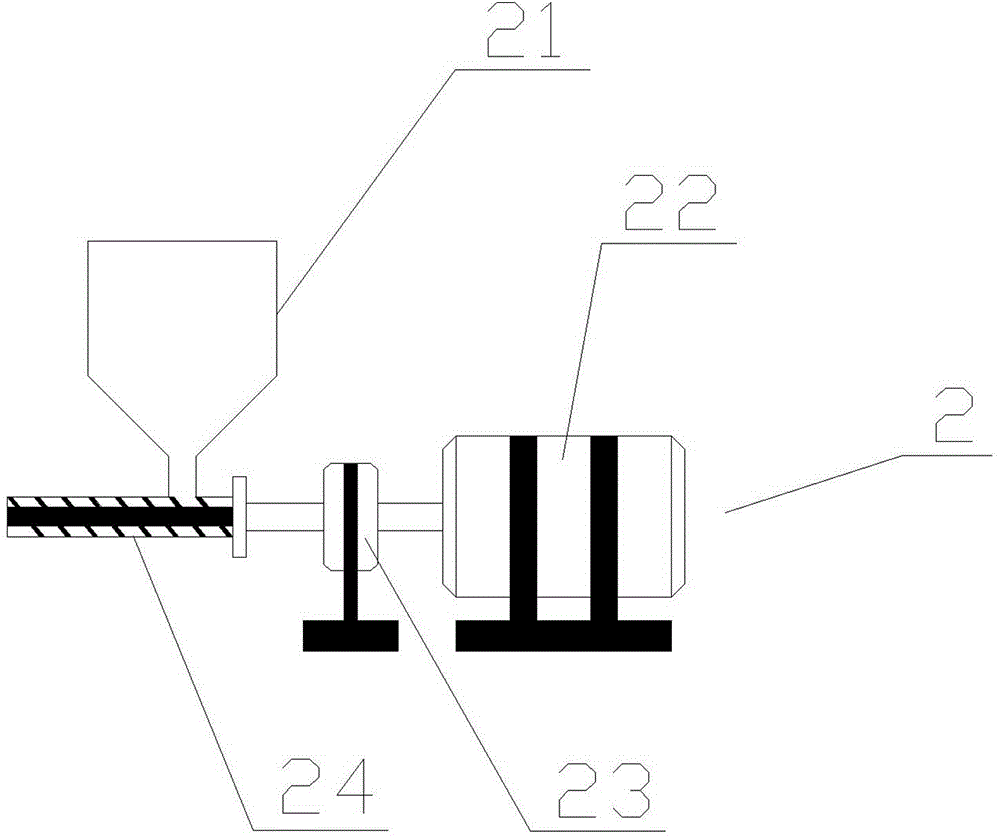

[0030] Adopt the present invention to prepare the pure aluminum matrix composite material that mass ratio content of tungsten powder is 15%, figure 1 with figure 2 It is a schematic diagram of the structure of the device used, and the preparation method is as follows:

[0031] Heating and melting industrial pure aluminum ingots in an intermediate frequency induction furnace and superheating to 750°C, refining the pure aluminum liquid with hexachloroethane and removing slag, then transferring the pure aluminum liquid to the atomization spray deposition device for aluminum or aluminum alloy liquid In the tundish, input high-pressure nitrogen, start the DC motor, drive the screw-type quantitative supplier to rotate through the DC motor, and supply the tungsten powder quantitatively to the high-pressure inert gas input pipe, and the pure aluminum liquid will flow out through the guide pipe downward, and the high-pressure inert gas Under the action of spraying, the pure aluminum ...

Embodiment 2

[0039] Adopt the present invention to prepare the 6063 aluminum alloy matrix composite material that the mass ratio content of tungsten powder is 10%, figure 1 with figure 2 It is a schematic diagram of the structure of the device used, and the preparation method is as follows:

[0040]Heat and melt industrial pure aluminum ingots in an intermediate frequency induction furnace and overheat to 800°C, then add industrial pure magnesium ingots with a mass percentage of 0.6% and industrial pure silicon with a mass percentage of 0.45%, stir and melt to form a 6061 aluminum alloy liquid, and use hexachloroethene After refining the 6061 aluminum alloy liquid and removing slag, transfer the 6061 aluminum alloy liquid to the tundish of the aluminum or aluminum alloy liquid atomization spray deposition device, input high-pressure argon gas, start the DC motor, and drive the screw type through the DC motor. The quantitative supplier rotates to quantitatively supply tungsten powder into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com