A kind of nanocomposite hydrogel dressing and its preparation method and application

A nanocomposite and hydrogel technology, applied in medical science, bandages, etc., can solve problems such as prone to inflammation, hinder wound healing, and bacterial drug resistance, so as to eliminate wound bacterial infection, promote infected wound repair, and improve The effect of antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

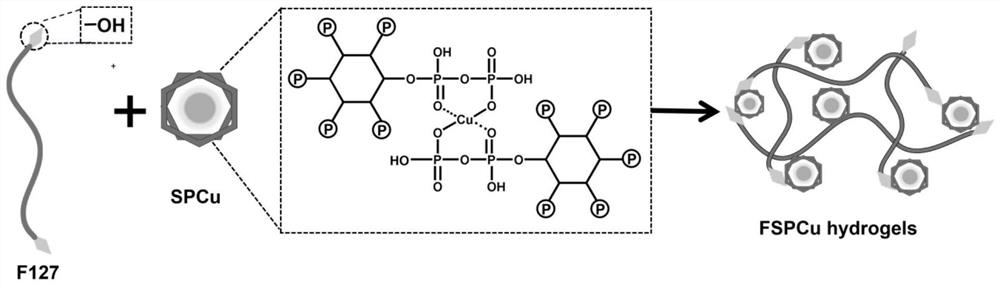

[0042] like figure 1 As shown, the preparation method of the present invention specifically comprises the following steps:

[0043] 1) Preparation of F127 aqueous solution. Add 9 mL of pure water and 2.2 g of F127 to the vial, ultrasonically shake it, and place it in a refrigerator at 0°C overnight until it is completely dissolved.

[0044] 2) Preparation of copper phytate nanoparticles. The F127 aqueous solution was placed in an ice-water bath for stirring, and 500 μL of sodium phytate with different concentrations was added. Subsequently, 500 μL of different concentrations of copper chloride aqueous solutions were added respectively, and the molar ratio of copper chloride to sodium phytate was 3:1. The final concentrations of sodium phytate in samples A, B, C, and D were 0%, 0.5%, 1.0%, and 2.0%, respectively, and the final concentration of F127 was 22%. After continuous stirring for 50 min, the pH of the reaction system was adjusted to 7.0-7.4 with 1 M NaOH solution.

...

Embodiment 1

[0056] 1) Preparation of F127 aqueous solution: 2.2 g of F127 was added to 9 mL of aqueous solution, sonicated and then placed in a refrigerator at 0°C overnight until completely dissolved.

[0057] 2) Preparation of copper phytate nanoparticles: the F127 aqueous solution was placed in an ice-water bath for stirring, and 500 μL (100 mg / mL) of sodium phytate was added dropwise. After stirring evenly, 500 μL of copper chloride aqueous solution containing 21.8 mg was added, and stirring was continued for 50 min. The molar ratio of copper chloride to sodium phytate was 3:1. The final concentration of sodium phytate in the sample was 0.5%, and the final concentration of F127 was 22%.

[0058] 3) Preparation of nanocomposite hydrogel: The pH of the reaction system was adjusted to 7.4 with 1M NaOH solution. Heating in a water bath at 37°C gradually changed the reaction system into a gel state, and the nanocomposite hydrogel dressing loaded with copper phytate was obtained, which wa...

Embodiment 2

[0060] 1) Preparation of F127 aqueous solution: 2.2 g of F127 was added to 9 mL of aqueous solution, sonicated and then placed in a refrigerator at 0°C overnight until completely dissolved.

[0061] 2) Preparation of copper phytate nanoparticles: the F127 aqueous solution was placed in an ice-water bath for stirring, and 500 μL (200 mg / mL) of sodium phytate was added dropwise. After stirring evenly, 500 μL of copper chloride aqueous solution containing 43.6 mg was added, and stirring was continued for 50 min. The molar ratio of copper chloride to sodium phytate was 3:1. The final concentration of sodium phytate in the sample was 1.0% and the final concentration of F127 was 22%.

[0062] 3) Preparation of nanocomposite hydrogel: The pH of the reaction system was adjusted to 7.4 with 1M NaOH solution. Heating in a water bath at 37°C gradually changed the reaction system into a gel state, and a nanocomposite hydrogel dressing loaded with copper phytate was obtained, which was n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com