Three-dimensional network silicon carbide enhanced metal-based composite material and preparation method thereof

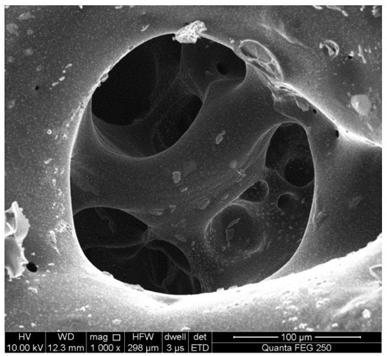

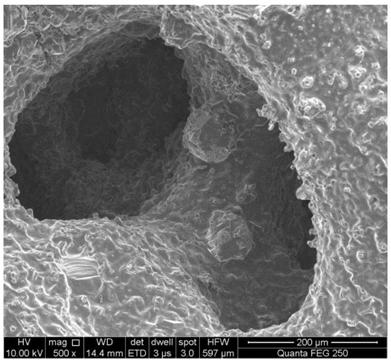

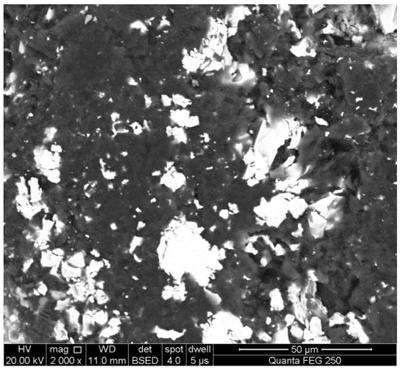

A technology of network silicon carbide and composite materials, which is applied in the field of three-dimensional network silicon carbide reinforced metal matrix composite materials and preparation, can solve problems such as interface reflection, and achieve the effects of good overall structure, small pore size and large porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Preparation of three-dimensional network silicon carbide reinforced high chromium cast iron composite material, high chromium cast iron components are C: 2.7-2.9, Si<0.8, Mn: 0.8-1, P<0.15, S<0.06, Cr: 26.5-27.5, Fe surplus quantity;

[0068] (1) The phenolic resin powder produced by Shanghai Sinopharm Group is dissolved in the isopropanol solution produced by Aladdin Reagent Co., Ltd. according to the mass ratio of 1:1, and the isopropanol solution containing 50% phenolic resin is prepared to obtain foaming Agents and binders;.

[0069] Take the wood flour of 100 mesh sieve and 5mm short carbon fibers (degummed) and carry out ball milling and mixing at a mass ratio of 5:0.2 until the short carbon fibers are evenly distributed in the wood flour to obtain a mixture; the foaming agent and binder obtained in the first step , the mixture, and the surfactant are mixed uniformly according to the mass ratio: 1:1:0.2 and stirred until there is no stratification phenomenon to o...

Embodiment 2

[0080] Preparation of three-dimensional network silicon carbide reinforced ZL104 aluminum alloy composite material, ZL104 aluminum alloy components are Si: 8.0-10.5, Mn: 0.2-0.5, Mg: 0.17-0.35, Al balance;

[0081] (1) The phenolic resin powder produced by Shanghai Sinopharm Group is dissolved in the isopropanol solution produced by Aladdin Reagent Co., Ltd. according to the mass ratio of 0.5:1, and the isopropanol solution containing 33.3% phenolic resin is prepared to obtain foaming Agents and binders;.

[0082] Take the wood flour with 100 mesh sieve and 2mm short carbon fibers (degummed) and carry out ball milling and mixing at a mass ratio of 5:0.1 until the short carbon fibers are evenly distributed in the wood flour to obtain a mixture; the foaming agent and binder obtained in the first step , the mixture, and the surfactant are mixed uniformly according to the mass ratio: 1:0.5:0.2 and stirred until there is no stratification phenomenon to obtain a mixed solution. tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com