Galvanizing carbon fiber foamed light metal and preparation method thereof

A light metal and carbon fiber technology, applied in the field of foamed light metal, can solve the problems of limited use scope, poor strength and toughness, etc., achieve wide practicability, and solve the effects of wettability and interface problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

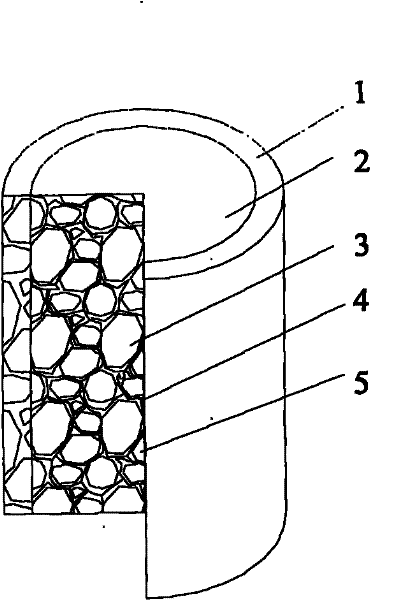

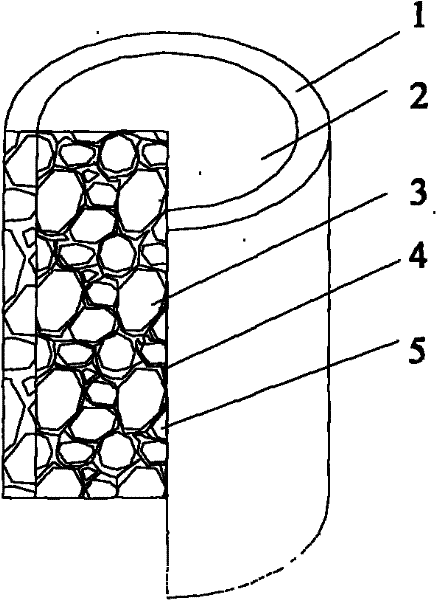

Image

Examples

Embodiment Construction

[0018] 1. Weigh zinc chloride 180g / L, ammonium chloride 80g / L, boric acid 25g / L, dextrin 20g / L and mix them together with water as solvent to make galvanizing solution, use pure zinc plate as anode, carbon fiber As the cathode, the cathode current density is 5-6A / dm 2 , the unsized 1K carbon fiber is introduced into the electroplating pool through 5 godet rollers of equal size for galvanizing treatment, and then galvanized carbon fiber is led into the washing tank through 5 godet rollers of equal size for cleaning in running water after 6 minutes, and then washed with Infrared drying, cut into short galvanized carbon fibers with a length of 1-3mm.

[0019] 2. Add 3g of galvanized short carbon fiber and 0.5% carboxymethyl starch ether dispersant to 50ml of saturated brine and stir evenly with ultrasonic vibration, then add 45g of 0.8-1.5mm salt particles into the above mixture and mix evenly Finally, put it into a container with a diameter of φ30mm and a height of 80mm, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com