Lithium battery composite diaphragm and preparation method thereof

A composite diaphragm and lithium battery technology, which is applied in secondary batteries, battery pack components, secondary battery repair/maintenance, etc., can solve the problems of poor wettability of ceramic coating diaphragms, and achieve ultra-high electrolyte absorption Liquid rate and retention rate, improved transferability, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] combine Figure 4 As shown, the embodiment of the present invention provides a preparation method of a lithium battery composite diaphragm, comprising steps:

[0033] S1. Disperse the pretreated montmorillonite in a solvent, stir and disperse evenly, and obtain a montmorillonite dispersion;

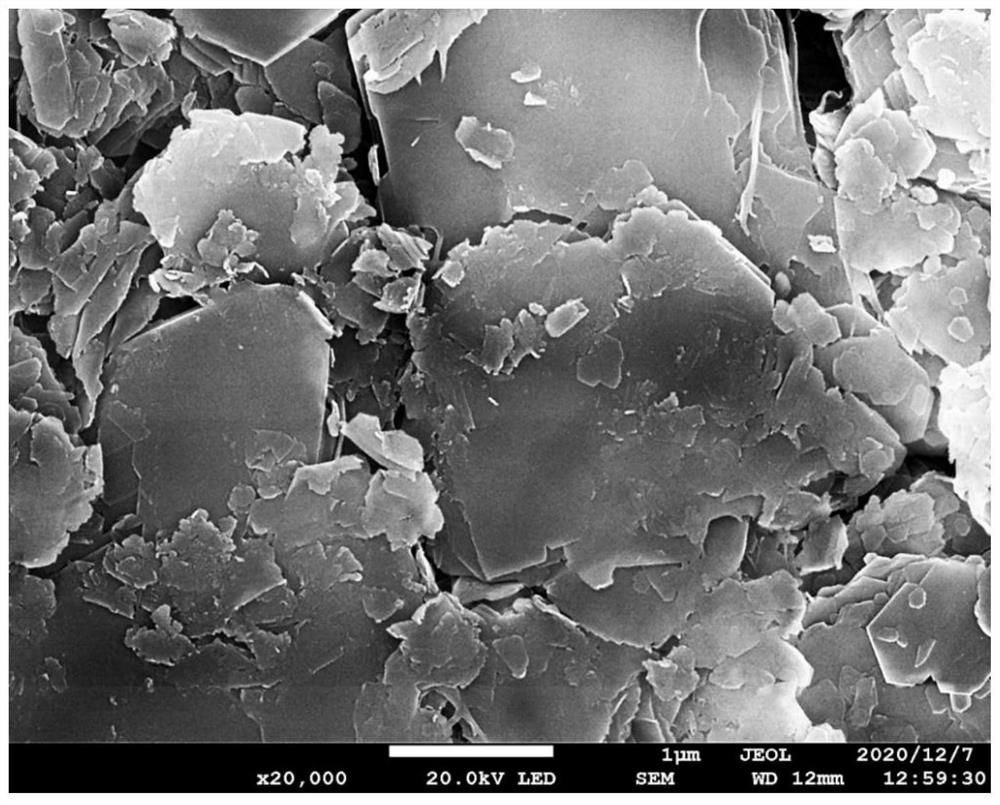

[0034] S2. Take the upper turbid liquid of the montmorillonite dispersion, place it in a centrifuge tube for centrifugation, and obtain montmorillonite nanosheets, place the montmorillonite nanosheets in an alkaline solution for infiltration, and then ultrasonically treat them in an ice bath to obtain Montmorillonite emulsion, finally solid-liquid separation, drying to obtain montmorillonite powder;

[0035] S3, uniformly mixing the montmorillonite powder and the oil-based binder to form an oil-based coating slurry;

[0036] S4. Coating the oil-based coating slurry on the surface of the lithium battery separator, and drying to obtain a lithium battery composite separator.

[003...

Embodiment 1

[0054] This embodiment provides a preparation method of a lithium battery composite diaphragm, and the specific steps are as follows:

[0055] (1) Place 5.00 g of 800 mesh montmorillonite powder after ball milling and 100 ml (102.60 g) of NMP (purity > 99.9%) in a solvent, at a speed of 2000 rpm, a temperature of 25 ° C in a constant temperature stirrer, Stir for 5 minutes, and then perform ultrasonic treatment to obtain a montmorillonite dispersion;

[0056] (2) Get the upper turbid liquid of the montmorillonite dispersion, centrifuge to obtain montmorillonite nanosheets with uniform size, put them into the alkaline solution and infiltrate, so that the weak alkali solution is fully embedded between the montmorillonite layers after infiltration, Then carry out ultrasonic treatment in an ice bath, separate solid and liquid, and dry to obtain montmorillonite powder;

[0057] (3) Dissolve 2.00g polyvinylidene fluoride (PVDF) in 100ml NMP solvent, configure 20.00mg / ml PVDF binder...

Embodiment 2

[0065] This embodiment provides a method for preparing a lithium battery composite diaphragm, which differs from Embodiment 1 in that:

[0066] In step (3), dissolve in 100ml NMP solvent with 2.00g polytetrafluoroethylene (PTFE), configure the PTFE binding agent of 20.00mg / ml; Take 5ml PTFE binding agent with pipette gun, add dropwise to 1.00g In the montmorillonite powder, mix evenly to form an oil-based coating slurry;

[0067] Other steps and parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com