Coating nanometer silicon carbide whisker toughened Ti(C,N) based metal ceramic material and preparing method thereof

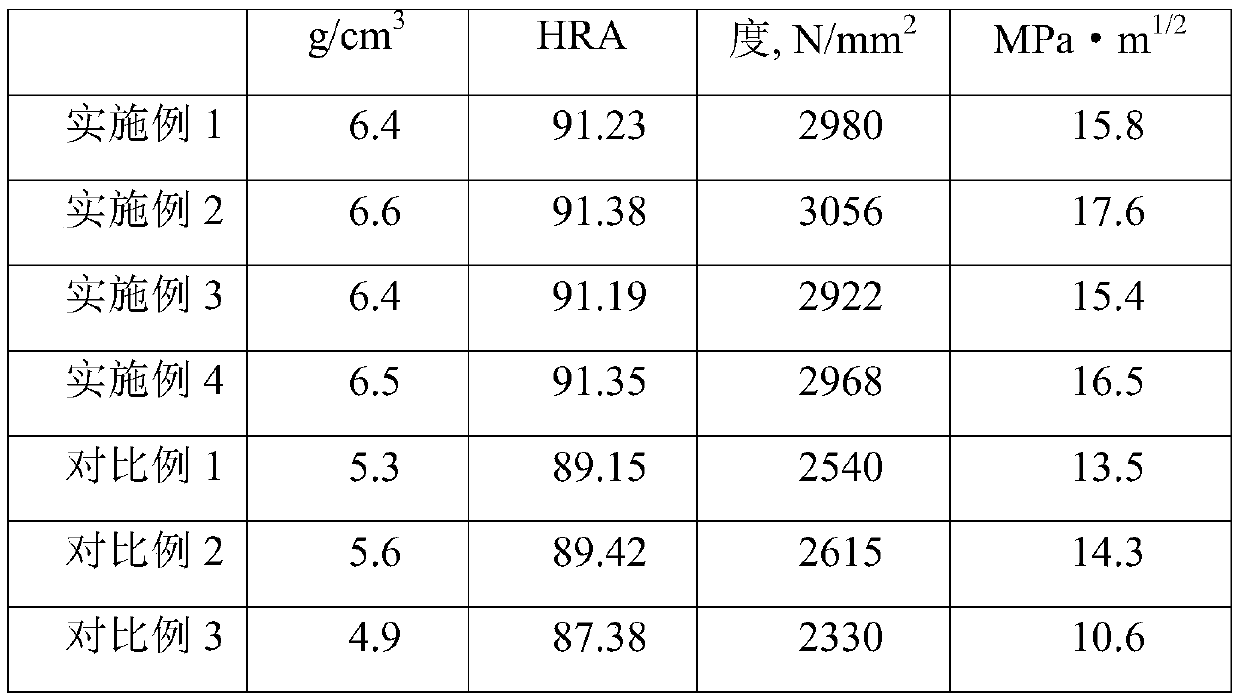

A nano-silicon carbide, ceramic material technology, applied in metal material coating process, coating, liquid chemical plating and other directions, can solve the problems of uneven material dispersion, small size of silicon carbide particles, large surface activity, etc. The effect of improved overall properties, hardness and flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

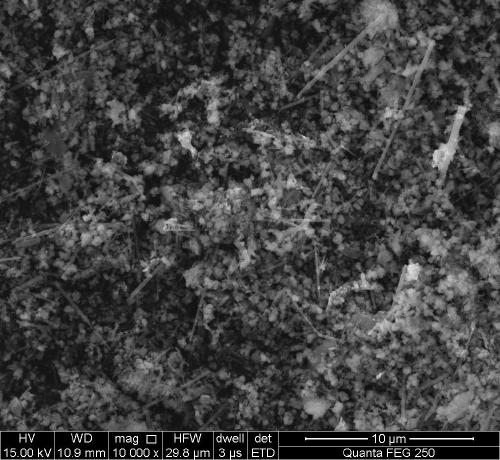

[0042]The present embodiment provides a coating nano-silicon carbide whisker toughened Ti(C,N)-based cermet material, which is composed of the following components in mass percentage: coating nano-silicon carbide 0.5wt%, Ti(C,N)-based Cermet powder 99.5wt%; The length of described coating nano-silicon carbide is 200nm, and diameter is 80nm, and the coating nano-silicon carbide of the present embodiment is preferably copper-coated nano-silicon carbide, and the thickness of copper layer is 10nm, and described Ti(C, The particle diameter of the N)-based cermet powder is 0.05 μm.

[0043] The preparation method of the above-mentioned coated nano-silicon carbide whisker toughened Ti(C,N)-based cermet material comprises the following steps:

[0044] S1. Silicon carbide copper plating treatment

[0045] S11. Sensitization treatment: place silicon carbide in concentrated HNO at 60°C 3 , stirred at 15000rpm for 80min, then placed silicon carbide in the sensitization solution, ultraso...

Embodiment 2

[0051] This embodiment provides a coating nano-silicon carbide whisker toughened Ti(C,N)-based cermet material, which is composed of the following components in mass percentage: coating nano-silicon carbide 2wt%, Ti(C,N)-based metal Ceramic powder 98wt%; The length of described coating nano-silicon carbide is 300nm, and diameter is 60nm, and the coating nano-silicon carbide of the present embodiment is preferably copper-coated nano-silicon carbide, and the thickness of copper layer is 20nm, and described Ti (C, N) The particle size of the base cermet powder is 5 μm.

[0052] The preparation method of the above-mentioned coated nano-silicon carbide whisker toughened Ti(C,N)-based cermet material comprises the following steps:

[0053] S1. Silicon carbide copper plating treatment

[0054] S11. Sensitization treatment: place silicon carbide in concentrated HNO at 65°C 3 , stirred at 15000rpm for 80min, then placed silicon carbide in the sensitization solution, ultrasonically os...

Embodiment 3

[0060] This embodiment provides a coating nano-silicon carbide whisker toughened Ti(C,N)-based cermet material, which is composed of the following components in mass percentage: coating nano-silicon carbide 3wt%, Ti(C,N)-based metal Ceramic powder 97wt%; The length of described coating nano-silicon carbide is 500nm, and diameter is 40nm, and the coating nano-silicon carbide of the present embodiment is preferably nickel-plated nano-silicon carbide, and nickel layer thickness is 16nm, and described Ti (C, N) The particle size of the base cermet powder is 4 μm.

[0061] The preparation method of the above-mentioned coated nano-silicon carbide whisker toughened Ti(C,N)-based cermet material comprises the following steps:

[0062] S1. Silicon carbide nickel plating treatment

[0063] S11. Sensitization treatment: place silicon carbide in concentrated HNO at 55°C 3 , stirred at 15000rpm for 100min, then placed silicon carbide in the sensitization solution, ultrasonically oscillat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com