Copper-graphite-tungsten disulfide nanotube self-lubricating composite material and preparation method thereof

A technology of tungsten disulfide and composite material, which is applied in the field of transition metal sulfide nanotube reinforced copper-based self-lubricating composite material and its preparation, can solve the problems of reduced lubricating performance, dependence on atmosphere, weak van der Waals force, etc. Excellent friction and wear properties, avoiding chemical reactions, and enhancing wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Copper-10wt% graphite-10wt% tungsten disulfide nanotube self-lubricating composite material

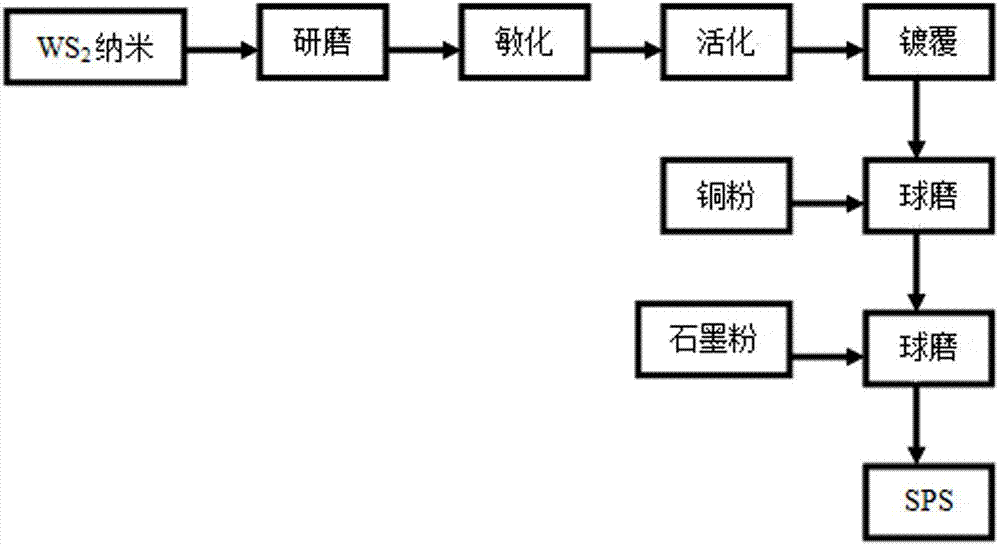

[0033] The process steps are as follows:

[0034] 1. Grinding: Grind 6g of tungsten disulfide nanotubes for 30 minutes, then place them in absolute ethanol for ultrasonic dispersion for 6 hours, remove the absolute ethanol and put them in a vacuum drying oven to dry at 100°C.

[0035] 2. Sensitization: place the ground and dried tungsten disulfide nanotubes in 0.1mol / L SnCl 2 The solution was ultrasonically oscillated for 30 minutes, centrifuged (15,000 rpm) and washed with deionized water until the solution was neutral (pH=7), then placed in absolute ethanol for ultrasonic dispersion for 6 hours, removed from absolute ethanol and placed Dry in a vacuum oven at 100°C.

[0036] 3. Activation: Place the sensitized tungsten disulfide nanotubes in 0.0024mol / L PdCl 2The solution was ultrasonically oscillated for 30 minutes, centrifuged (15000 rpm) and washed with water...

Embodiment 2

[0043] Example 2: Preparation of copper-7wt% graphite-3wt% tungsten disulfide nanotube self-lubricating composite material

[0044] The preparation method of this example is the same as Example 1, the difference is that the mass ratio of copper, graphite and tungsten disulfide nanotubes is 90:7:3, and the discharge plasma sintering is carried out under vacuum conditions, and the vacuum degree is 10 -4 Pa, the sintering temperature is 800°C, the heating rate is 50°C / min, the pressure is 50MPa, and the holding time is 10min.

[0045] The copper-7wt% graphite-3wt% tungsten disulfide nanotube self-lubricating composite material with a density of 97.8%, a Brinell hardness of 85.7HB and a flexural strength of 193.2MPa was prepared by the above process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com