High-entropy alloy system high-temperature brazing filler metal

A technology of high-temperature brazing material and high-entropy alloy, applied in metal processing equipment, welding/cutting media/materials, welding equipment, etc., can solve problems such as poor high temperature resistance and large residual stress, and achieve good brazing effect and reliable performance Strong tonality and the effect of relieving residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

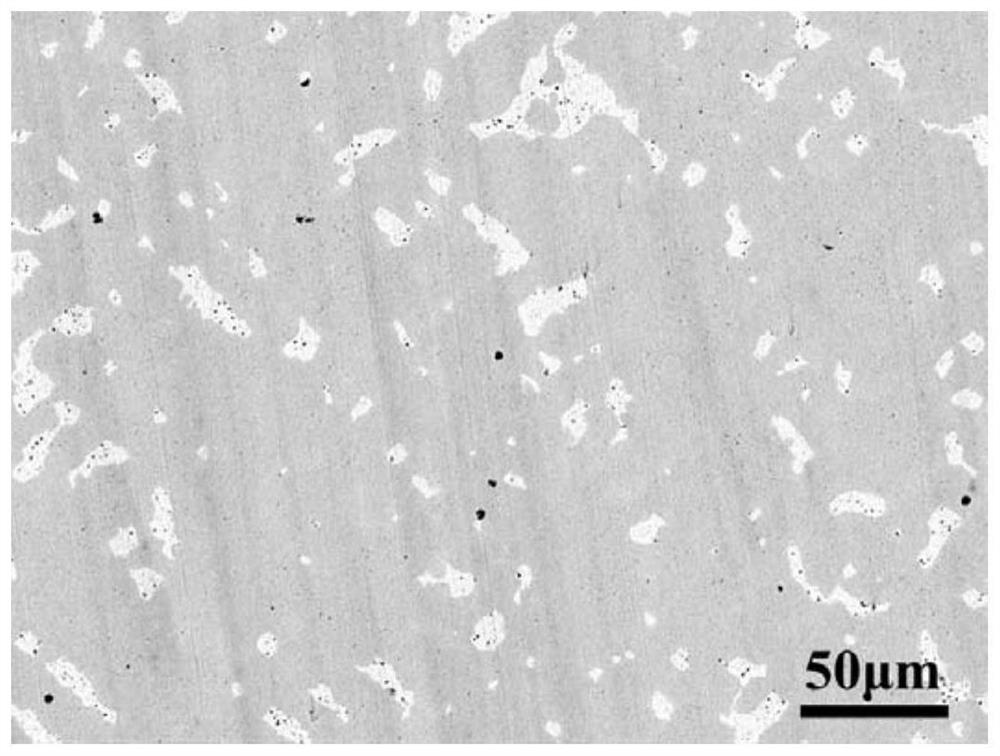

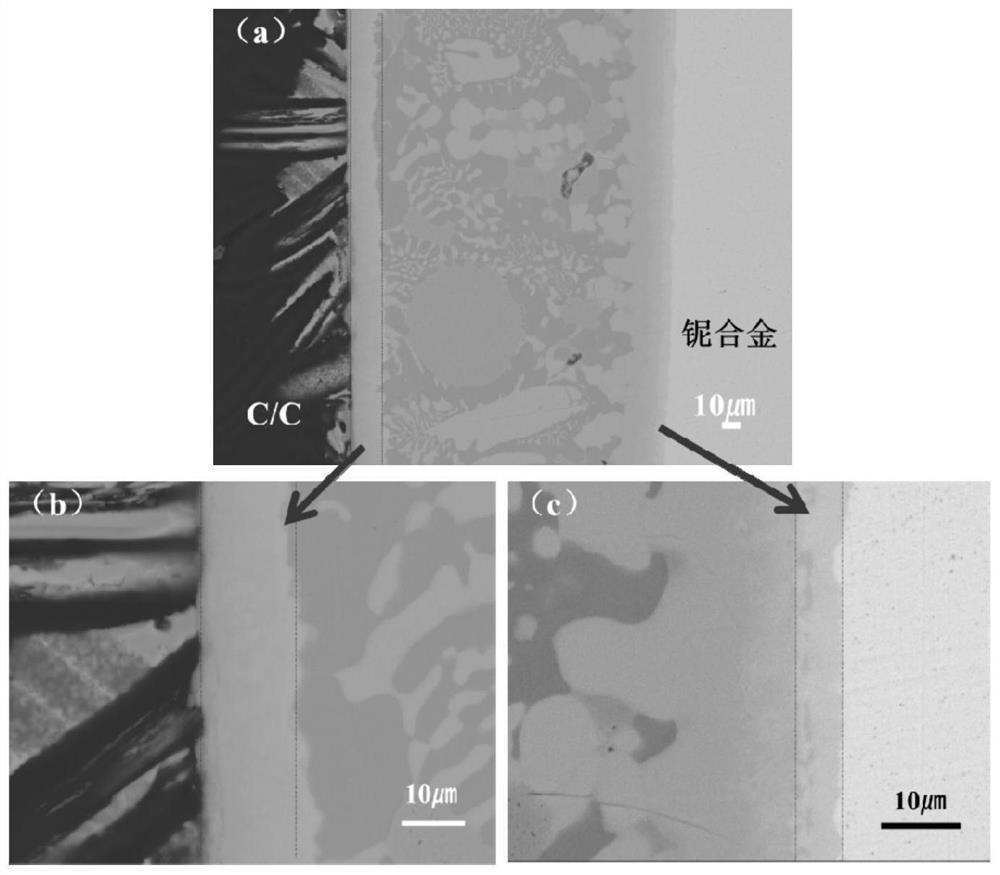

[0019] Specific implementation mode 1: The chemical formula of a high-entropy alloy-based high-temperature solder in this implementation mode is CoCrFeNiCu x Ti y , CoCrFeNiCu x Ti y The value range of x is 0.5~2, the value range of y is 0.1~0.5, and the molar ratio of Co, Cr, Fe, Ni, Cu and Ti is 1:1:1:1:(0.5~2): (0.1~0.5).

specific Embodiment approach 2

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the structure of a high-entropy alloy-based high-temperature solder is an fcc structure solid solution. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the yield strength of a high-entropy alloy high-temperature solder is 200MPa-600MPa, and the elongation is greater than 40%. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com