TiB2-C composite cathode for aluminum electrolysis and preparation method thereof

A composite cathode and aluminum electrolysis technology, applied in the field of cathode materials for aluminum electrolysis, can solve the problems of uneven coating thickness, poor corrosion resistance to cryolite molten salt and aluminum liquid, shortened cathode life, etc., and achieve uniform and good material properties. Application effect, effect of avoiding oxidation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

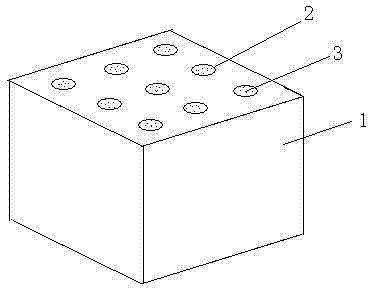

[0045] A) First, 50wt% of titanium boride powder with a particle size of 3-10μm, 20wt% of artificial graphite with a particle size of 60-150μm, 1.1wt% of graphitized mesocarbon microspheres with a particle size of 10-15μm, and a particle size of 50-100μm carbon fiber powder 1wt%, 3-5mm graphitized carbon fiber 2wt%, furan resin with a viscosity-average molecular weight of 4000-6000 3wt%; E-44 epoxy resin 3wt%, particle size 75-150μm modification 2.5wt% asphalt, 18wt% mixed solvent, 0.25wt% p-toluenesulfonic acid, and 0.15wt% liquid curing agent are weighed in proportion, added to a mixer and kneaded. The kneading temperature is 15°C, and the relative humidity in the air is 30%. The time is 6h, and the desired slurry is obtained. The mixed solvent is prepared from butyl acetate, absolute ethanol and butanone in a volume ratio of 4:3:20; the liquid curing agent is prepared from sulfuric acid, phosphoric acid and ethanol in a volume ratio of 10:3:25 . Such as figure 1 As shown...

Embodiment 2

[0055] First, 40wt% of titanium boride powder with a particle size of 3-10μm, 18wt% of artificial graphite with a particle size of 60-150μm, 3wt% of graphitized mesocarbon microspheres with a particle size of 10-15μm, and a particle size of 50-100μm 3wt% of carbon fiber powder, 3wt% of graphitized carbon fiber of 3-5mm, 3.5wt% of furan resin with a viscosity average molecular weight of 4000-6000; 3.5wt% of E-44 epoxy resin, modified pitch with a particle size of 75-150μm 3wt%, mixed solvent 22wt%, p-toluenesulfonic acid 0.4wt%, and liquid curing agent 0.6wt% were weighed in proportion, added to the mixer and kneaded and stirred. The kneading temperature was 28 ° C, the relative humidity in the air was 50%, and the kneading time was 3h, obtain required slurry;

[0056] Use a drilling tool to drill a through hole on the two opposite conductive surfaces of the carbon block of the all-graphite matrix, the hole diameter is 8mm, and the center distance of the hole is 12mm; inject th...

Embodiment 3

[0063] First, 44wt% of titanium boride powder with a particle size of 3-10μm, 13wt% of artificial graphite with a particle size of 60-150μm, 2wt% of graphitized mesocarbon microspheres with a particle size of 10-15μm, and a particle size of 50-100μm 2wt% of carbon fiber powder, 4wt% of graphitized carbon fiber of 3-5mm, 6wt% of furan resin with a viscosity average molecular weight of 4000-6000; 3wt% of E-44 epoxy resin, 4wt% of modified pitch with a particle size of 75-150μm , mixed solvent 20wt%, p-toluenesulfonic acid 1wt%, and liquid curing agent 1wt% were weighed in proportion, added to a mixer and kneaded and stirred. The kneading temperature was 35 ° C, the relative humidity in the air was 70%, and the kneading time was 6 hours. need slurry;

[0064] Use a drilling tool to drill a through hole on the two opposite conductive surfaces of the carbon block of the all-graphite matrix, the hole diameter is 6mm, and the distance between the holes is 10mm; inject the above slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com