Silica gel contact lenses surface modification method and preparation method of colorful contact lenses

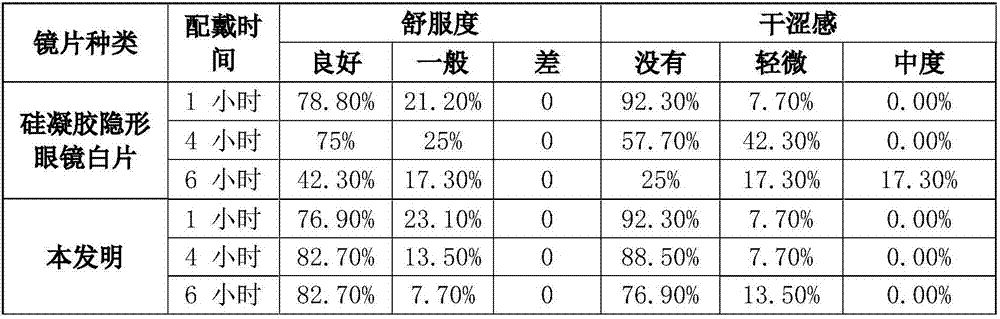

A silicone gel contact lens, surface modification technology, applied in glasses/goggles, optics, instruments, etc., can solve the problems of insufficient hydrophilicity of silicone gel contact lenses, affecting the wearing effect, etc., to achieve improved wearability Wearing effect, improvement of wearing effect, effect of ensuring oxygen permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Preparation of silicone gel contact lens lenses

[0029] The silicone gel contact lens used in the present invention can be a cast or turned silicone gel contact lens made by photopolymerization or thermal polymerization. The casting or turning molding process used can refer to common literature and industrial practice. The raw material used can be a silicon-containing prepolymer or a mixture of each monomer and a silicon-containing prepolymer. Preferably, the monomer used is a vinyl monomer containing amide (NH), or containing one or more functional groups of carboxyl (COOH) or hydroxyl (OH). For the preparation of silicon-containing prepolymers, please refer to U.S. Patent Nos. 4136250A, 5962548A, and 5563184A. In this example, the raw material formula used is: 26.97% of siloxane-containing macromonomers, 16.75% of TRIS (3-tris(methyl-siloxy)silylpropyl methacrylate) , 32.64% DMA (N,N-dimethylacrylamide), 22.64% denatured ethanol and 1.0% 2-hydroxy-2-methyl...

Embodiment 2

[0030] Example 2: Preparation of yellow contact lenses

[0031] Weigh 45 grams of 2-hydroxyethyl methacrylate, 0.8 grams of methacrylic acid, 1.5 grams of methyl methacrylate, 15.70 grams of ethyl lactate, 37.5 grams of cyclopentanone and 0.04 grams of azobisisobutylene. -0.6 g of mercaptoethanol, put it in a glass reaction flask and mix well, polymerize at 70 degrees for 6 hours, then add 0.04 g of methyl ether hydroquinone to the glass reaction flask, stir evenly and stop the reaction, with a gradient water content of biological high The synthesis of the polymer is complete.

[0032] Weigh 412 grams of the above-mentioned biopolymer, 88 grams of yellow iron oxide pigment, 3.1 grams of EFKA5054 additives, 2.2 grams of Byk307 additives, and 46 grams of cyclopentanone in a dispersing mill. Add appropriate grinding media and grind until the pigment particles are fine. The degree is less than 10μm, and the color coating slurry with gradient water content is prepared. Next, weigh 50 ...

Embodiment 3

[0034] Example 3: Preparation of purple contact lenses

[0035] Weigh 7.5 g of N-vinylpyrrolidone, 37.8 g of 2-hydroxyethyl methacrylate, 0.5 g of methacrylic acid, 0.4 g of acrylic acid, 1.4 g of methyl methacrylate, 16.1 g of ethyl lactate, and 35.7 g of pentanone, 0.035 g of azobisisobutyronitrile, 0.55 g of 2-mercaptoethanol, put them in a glass reaction flask and mix well, polymerize at 75°C for 5 hours, and then add methyl ether hydroquinone to the glass reaction flask Stir 0.033 g uniformly and stop the reaction, and the biopolymer with gradient water content is synthesized.

[0036] Weigh 404 grams of the above-mentioned biopolymer, 132 grams of high-purity purple pigment, 9.28 grams of EFKA5054 additives, 6.24 grams of Byk307 additives, and 26 grams of cyclopentanone in a dispersing mill. Add an appropriate amount of grinding media and grind until the pigment particles are fine. The degree should be less than 10 μm, and a color coating slurry with a gradient water content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com