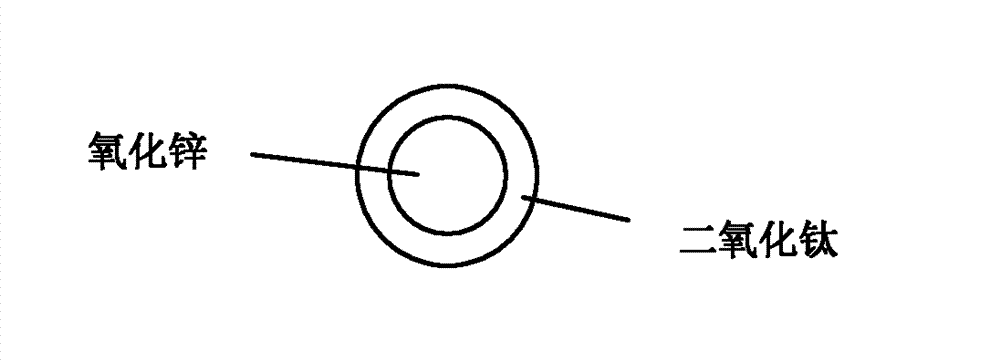

Nano-sized core-shell composite material used for cosmetics and preparation method thereof

A composite material and nano-core-shell technology, which is applied in the field of nano-core-shell composite materials and preparation, can solve the problems of reduced use effect, uneven distribution, skin whitening, etc., and achieve uneven dispersion, effective composite materials, and solutions The effect of dry skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add 1g of nano-zinc oxide powder with a particle size of 50nm into a 100ml beaker, then add 0.4mol / L titanium tetrachloride solution into 50ml, heat up to 75°C, control the speed at 500rpm, and stir for 30min. Stirring was stopped, and the obtained mixed solution was filtered, washed with deionized water, dried in a vacuum oven, and placed in a muffle furnace for sintering at 500°C for 30 minutes. The thickness of the obtained nano zinc oxide core is about 50nm, and the thickness of the titanium dioxide shell is about 10nm.

Embodiment 2

[0017] Add 1g of nano zinc oxide powder with a particle size of 50nm into a 100ml beaker, then add 0.8mol / L titanium tetrachloride solution into 50ml, heat up to 75°C, control the speed at 500rpm, and stir for 30min. Stirring was stopped, and the obtained mixed solution was filtered, washed with deionized water, dried in a vacuum oven, and placed in a muffle furnace for sintering at 500°C for 30 minutes. The thickness of the obtained nanometer zinc oxide core is about 50nm, and the thickness of the titanium dioxide shell is about 15nm.

Embodiment 3

[0019] Add 1g of nano-zinc oxide powder with a particle size of 50nm into a 100ml beaker, then add 0.4mol / L titanium tetrachloride solution into 50ml, heat up to 85°C, control the speed at 500rpm, and stir for 60min. Stirring was stopped, and the obtained mixed solution was filtered, washed with deionized water, dried in a vacuum oven, and placed in a muffle furnace for sintering at 500°C for 30 minutes. The thickness of the obtained nano zinc oxide core is about 50nm, and the thickness of the titanium dioxide shell is about 20nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com