Alpha-alumina-based abrasive containing sheet-shaped structures, and preparation method thereof

An alumina-based, sheet-like structure technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem of high cost and achieve the effects of high grinding efficiency, long durability, mature and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 16.8 kg of purified water and 42 kg of semi-finished boehmite with a water content of 70% to a 150-liter blender with vacuum function, start the blender to stir and beat into a slurry, add 1.6 kg of 20% nitric acid solution, and stir for 5 minutes. Stop stirring, slurry is input into colloid mill, further refines slurry, slurry is transferred in the former mixer after coming out from colloid mill, vacuumizes, starts mixer, adds the nitric acid of 3 kilograms of 20%, stirs evenly. After a while, a gel forms.

[0036] Transfer the above-prepared gel into a stainless steel tray and put it in an oven at 100°C until the gel becomes brittle and cracks, becoming fragments with a diameter of several millimeters to more than ten millimeters, and some particles can reach several centimeters , the size of the pieces depends on the drying speed. The faster the drying speed, the smaller the particles.

[0037] The dried fragments are further crushed, and the required particle ...

Embodiment 2

[0043] In a 150-liter blender with vacuum function, add 0.6 kg of pure water, 62.5 kg of semi-finished boehmite with a water content of 80%, add 1.6 kg of 20% nitric acid solution, and stir for 5 minutes. Stop stirring, slurry is input colloid mill, further thins slurry, slurry is transferred in the former mixer after coming out from colloid mill, vacuumizes, starts mixer, adds the nitric acid of 3.2 kilograms of 20%, stirs evenly. After a while, a gel forms. Following the same example 1, but the difference is: when preparing the modifier solution, 10 kilograms of aqueous solution contained 520 grams of yttrium nitrate hexahydrate, 815 grams of lanthanum nitrate hexahydrate, 983 grams of magnesium nitrate hexahydrate and 39 grams of cobalt nitrate hexahydrate .

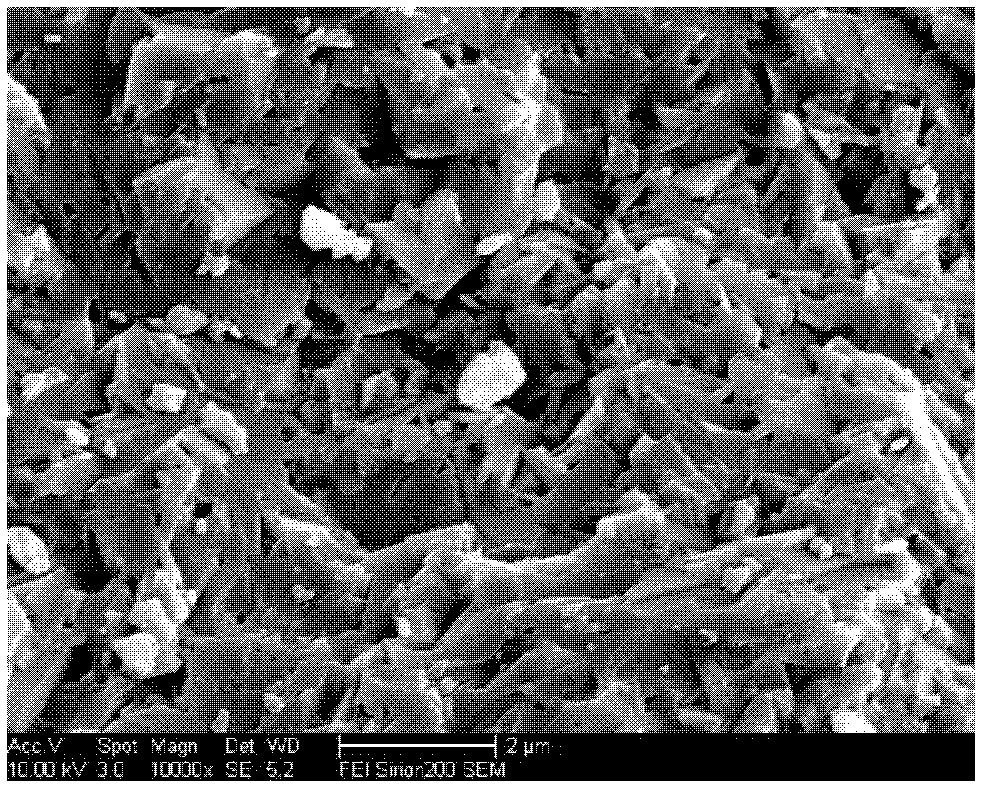

[0044] The resulting product has a particle density of 3.90 g / cm3 and a microhardness of 20.5 Gpa. The grains of ceramic microcrystalline abrasive particles are about 2 microns, containing a flaky structure, and the ...

Embodiment 3

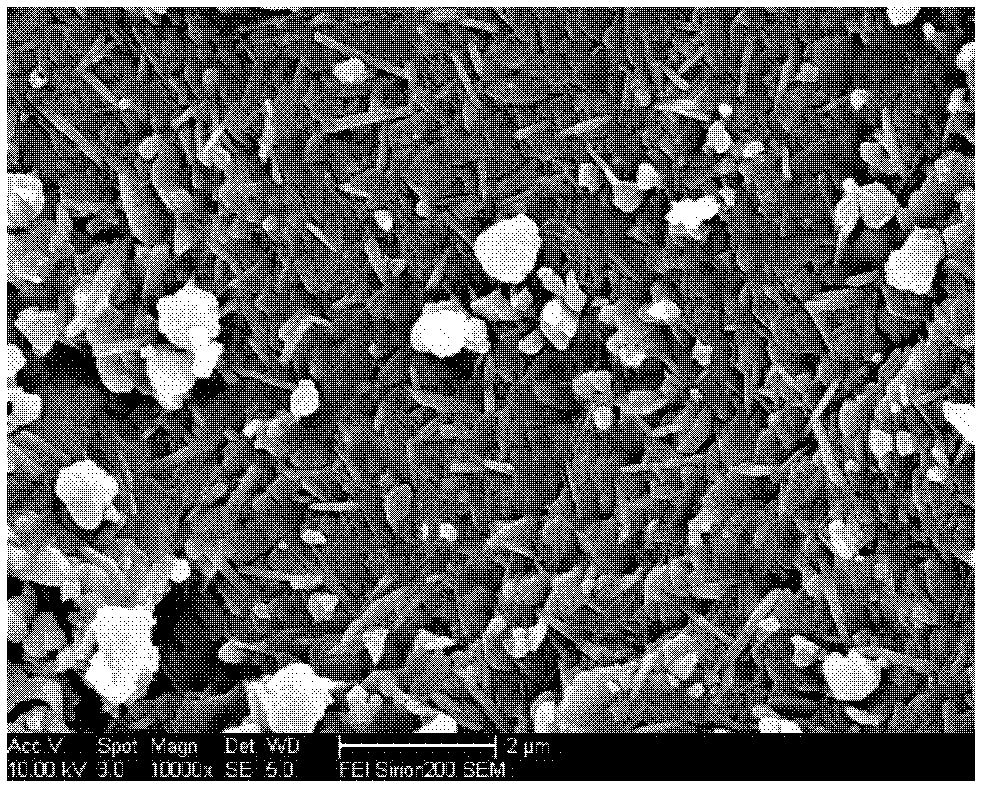

[0047] In a 30-liter kneader with a vacuum function, add 10 kilograms of water-containing 75% boehmite semi-finished products, add the dried gel in Example 1, crush and sieve, 2 kilograms of fine gel particles under a 120 mesh sieve, and start kneading Machine kneading for 5 minutes, then add 0.9 kg of nitric acid with a concentration of 20%, 2 kg contains 132 grams of yttrium nitrate hexahydrate, 207 grams of lanthanum nitrate hexahydrate, 250 grams of magnesium nitrate hexahydrate and 15 grams of cobalt nitrate hexahydrate aqueous solution, continue Start the kneader and knead for 60 minutes, then take it out and dry it, crush it, sieve it, calcinate it at 800°C for 10 minutes, and then sinter it at 1500°C for 60 minutes. The resulting product has a particle density of 3.90 g / cubic centimeter, a hardness of 20 Gpa, and contains a flake structure, and the sum of yttrium oxide, lanthanum oxide, magnesium oxide and cobalt oxide accounts for about 4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Grain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com