High-strength zinc-plated steel sheet and high-strength steel sheet having superior moldability, and method for producing each

A high-strength steel plate and manufacturing method technology, applied in the direction of manufacturing tools, chemical instruments and methods, metal rolling, etc., can solve problems such as insufficient formability, brittle fracture, and processing difficulties, and achieve excellent high-speed tensile properties and formability excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

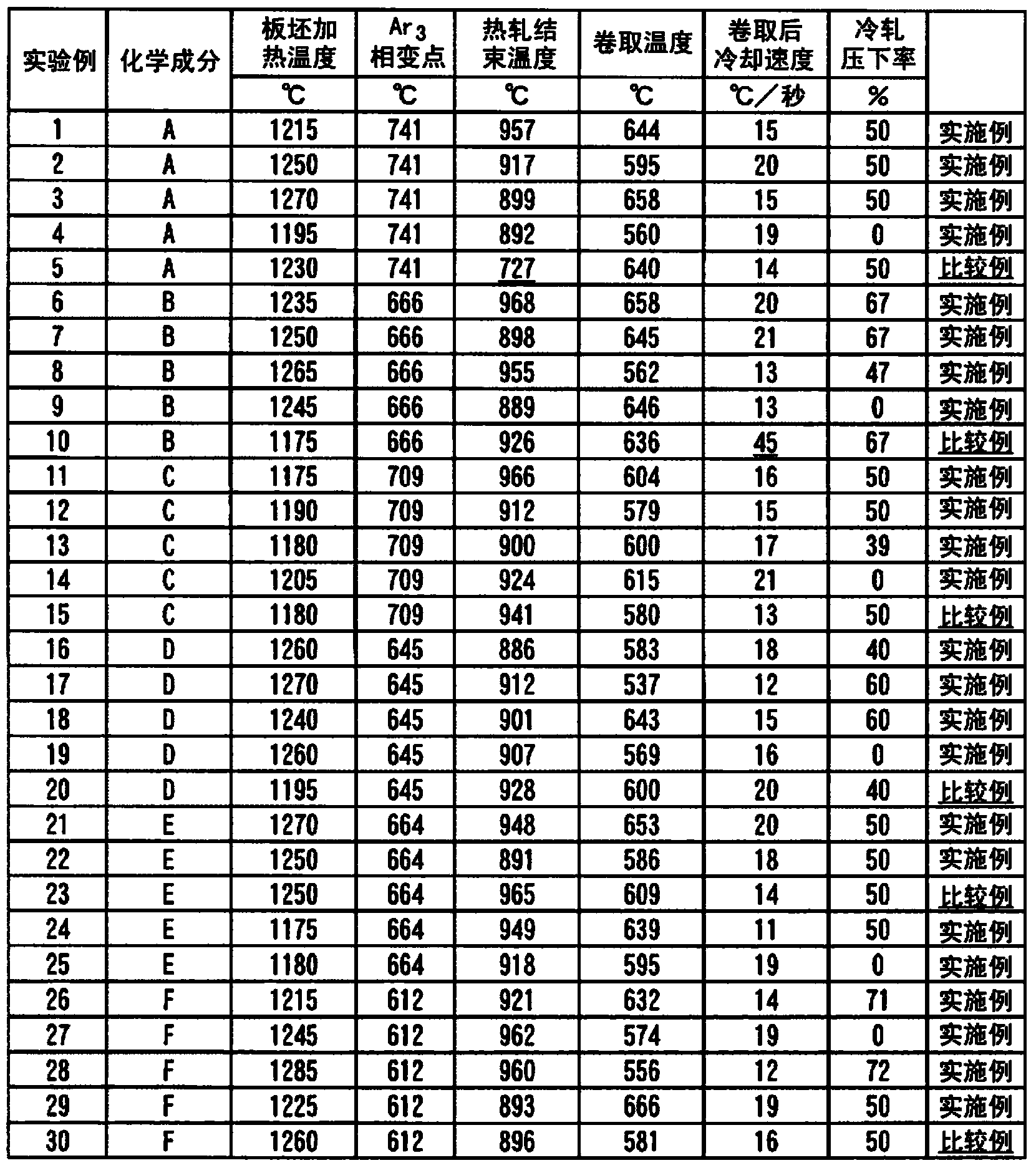

[0139] Slabs having chemical components (compositions) of A to AL shown in Tables 1 and 2 were cast, and hot rolling, cooling, coiling, and pickling were performed under the conditions shown in Tables 3 to 5 immediately after casting. In Experimental Examples 4, 9, 14, 19, 25, 29, 87, and 90, cold rolling under the conditions shown in Tables 3 to 6 was implemented after pickling the other Experimental Examples with the hot-rolled steel sheets as they were. Then, annealing was performed under the conditions shown in Tables 7 to 10 to form steel sheets of Experimental Examples 1 to 114.

[0140] In addition, Experimental Example 102 was an example exceeding the upper limit of the amount of Cu, and the result of the weldability test performed after hot rolling was bad, so the subsequent tests were discontinued.

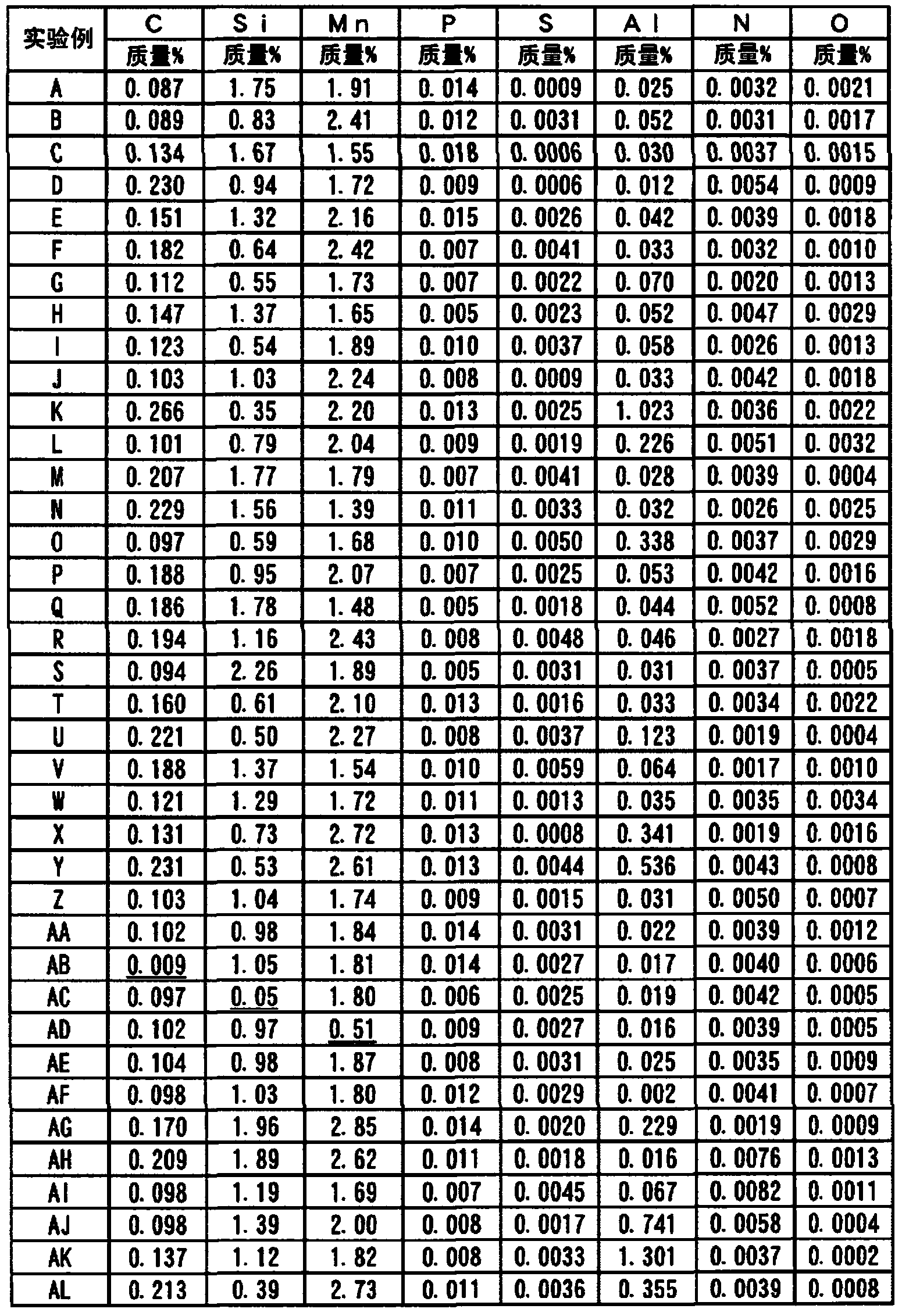

[0141] Table 1

[0142]

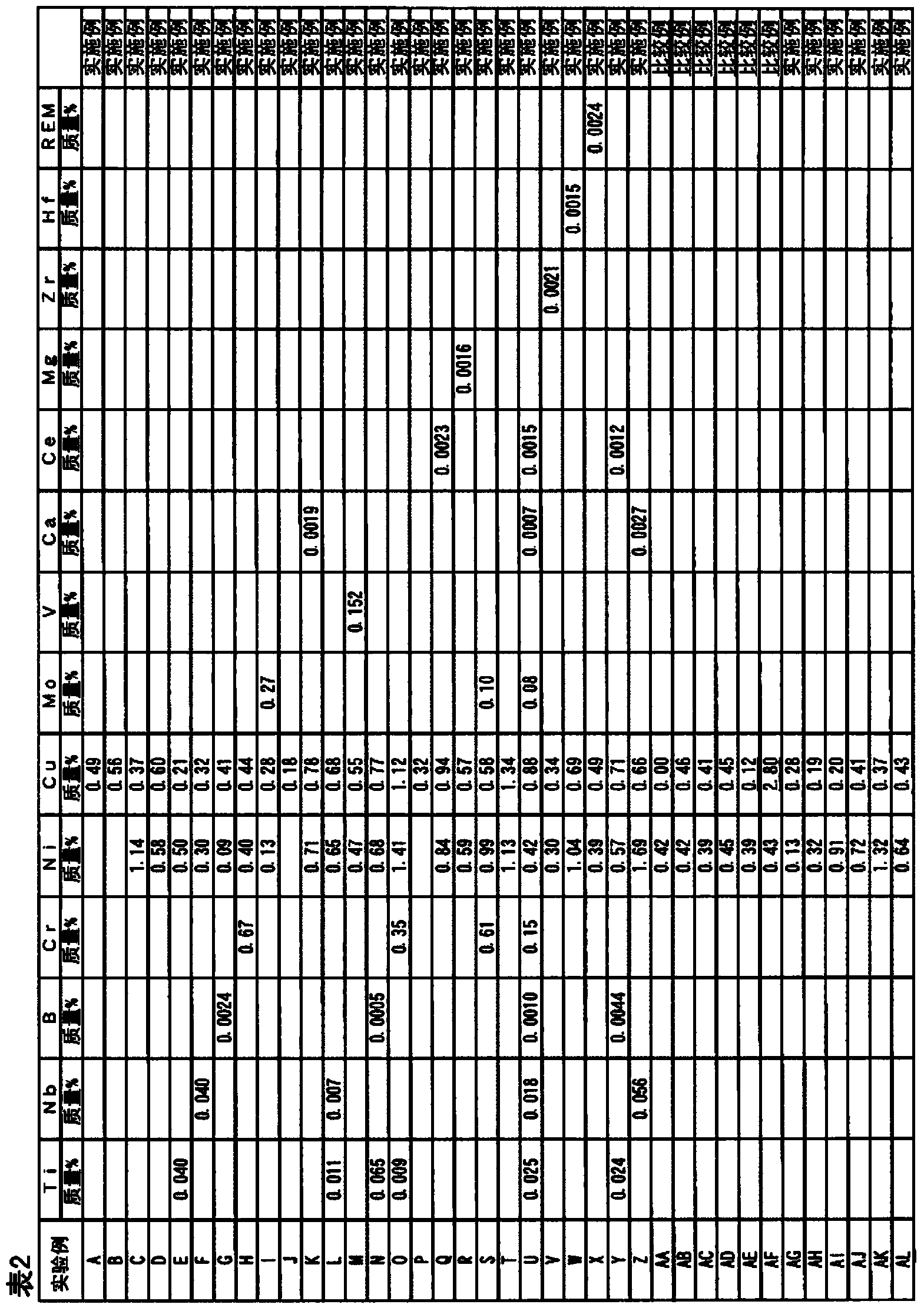

[0143]

[0144] table 3

[0145]

[0146] Table 4

[0147]

[0148] table 5

[0149]

[0150] Table 6

[0151]

[0152] ...

experiment example 5

[0190] Experimental Example 5 is an example in which the hot rolling finish temperature is low, and since the microstructure is a heterogeneous structure elongated in one direction, the ductility and stretch-flangeability are inferior.

experiment example 10

[0191] In Experimental Example 10, the cooling rate after coiling was high, the precipitation of Cu particles in the hot rolling process was insufficient, and the ratio of Cu particles incoherent with bcc iron was low, so the stretch flangeability was inferior.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com