Preparation method of hydrogen bond acceptor oxygen atom-rich super-crosslinked polymer and application of super-crosslinked polymer

A polymer and super-crosslinking technology, applied in the direction of alkali metal oxides/hydroxides, separation methods, alkali metal compounds, etc., can solve the problem of difficult to obtain super-crosslinked polymers, limited improvement ability, limited modification ability, etc. problems, to achieve the effect of improving selective adsorption capacity, increasing selective adsorption capacity, and improving selective adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Preparation of precursor polymers rich in hydrogen bond acceptor oxygen atoms:

[0039] Add 20 g of chloromethylated polystyrene low-crosslinked polymer to N,N-dimethylformamide (DMF), and seal and swell overnight at room temperature. Install a reflux condenser and a mechanical stirrer, add phenol and 10g of basic catalyst K at room temperature 2 CO 3 , stirred for 30 minutes until completely dissolved, raised the temperature to 90-95°C, and reacted at this temperature for 24 hours, washed the obtained product alternately with hot water, cold water, and absolute ethanol for 3-4 times until colorless, and then washed with ethanol, The volume ratio of methanol and water is 1:1:1, extracting in a Soxhlet extractor for 8-24 hours, ordinary drying for 12 hours, and then vacuum drying for 24 hours to obtain the precursor polymer P;

[0040] 2) Friedel-Crafts alkylation reaction:

[0041] Add 10 g of precursor polymer P and 120 mL of 1,2-dichloroethane into a dry three-n...

Embodiment 2

[0052] 1) Preparation of precursor polymers rich in hydrogen bond acceptor oxygen atoms:

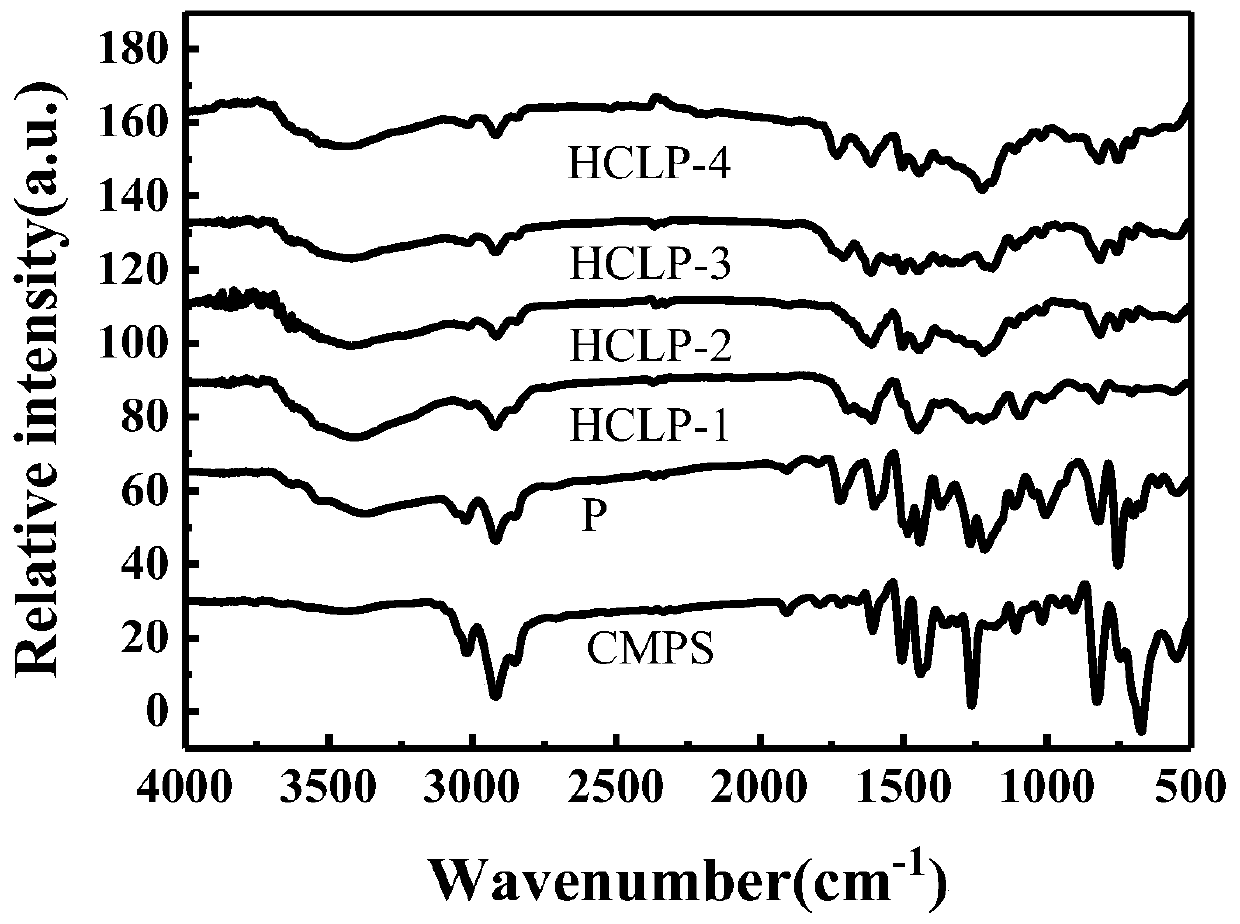

[0053] Add 20 g of chloromethylated polystyrene low-crosslinked polymer to N,N-dimethylformamide (DMF), and seal and swell overnight at room temperature. Install reflux condenser and mechanical stirrer, add naphthol and 10g basic catalyst K at normal temperature 2 CO 3 , stirred for 30 minutes until completely dissolved, raised the temperature to 90-95°C, and reacted at this temperature for 24 hours, washed the obtained product alternately with hot water, cold water, and absolute ethanol for 3-4 times until colorless, and then washed with ethanol, The volume ratio of methanol and water was 1:1:1, extracted in a Soxhlet extractor for 8-24 hours, dried for 12 hours in a normal way, and then dried in vacuum for 24 hours to obtain the precursor polymer P; infrared characterization showed that the precursor polymer P was -1 The absorption peak corresponding to the C-Cl stretching vibration ...

Embodiment 3

[0063] 1) Preparation of precursor polymers rich in hydrogen bond acceptor oxygen atoms:

[0064] Add 20 g of chloromethylated polystyrene low-crosslinked polymer to N,N-dimethylformamide (DMF), and seal and swell overnight at room temperature. Install reflux condenser and mechanical stirrer, add catechol and 10g basic catalyst Na at normal temperature 2 CO 3 , stirred for 30 minutes until completely dissolved, raised the temperature to 90-95°C, and reacted at this temperature for 24 hours, washed the obtained product alternately with hot water, cold water, and absolute ethanol for 3-4 times until colorless, and then washed with ethanol, The volume ratio of methanol and water was 1:1:1, extracted in a Soxhlet extractor for 8-24 hours, dried for 12 hours in a normal way, and then dried in vacuum for 24 hours to obtain the precursor polymer P; infrared characterization showed that the precursor polymer P was -1 The absorption peak corresponding to the C-Cl stretching vibration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com