Prefabricated and assembled tower crane foundation

A prefabricated assembly and foundation technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of small contact area between the foundation and the ground, easy damage of shear-resistant concave-convex parts, artificial waste of anchor bolts, etc., to shorten the pouring time, foundation The effect of uniform force and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

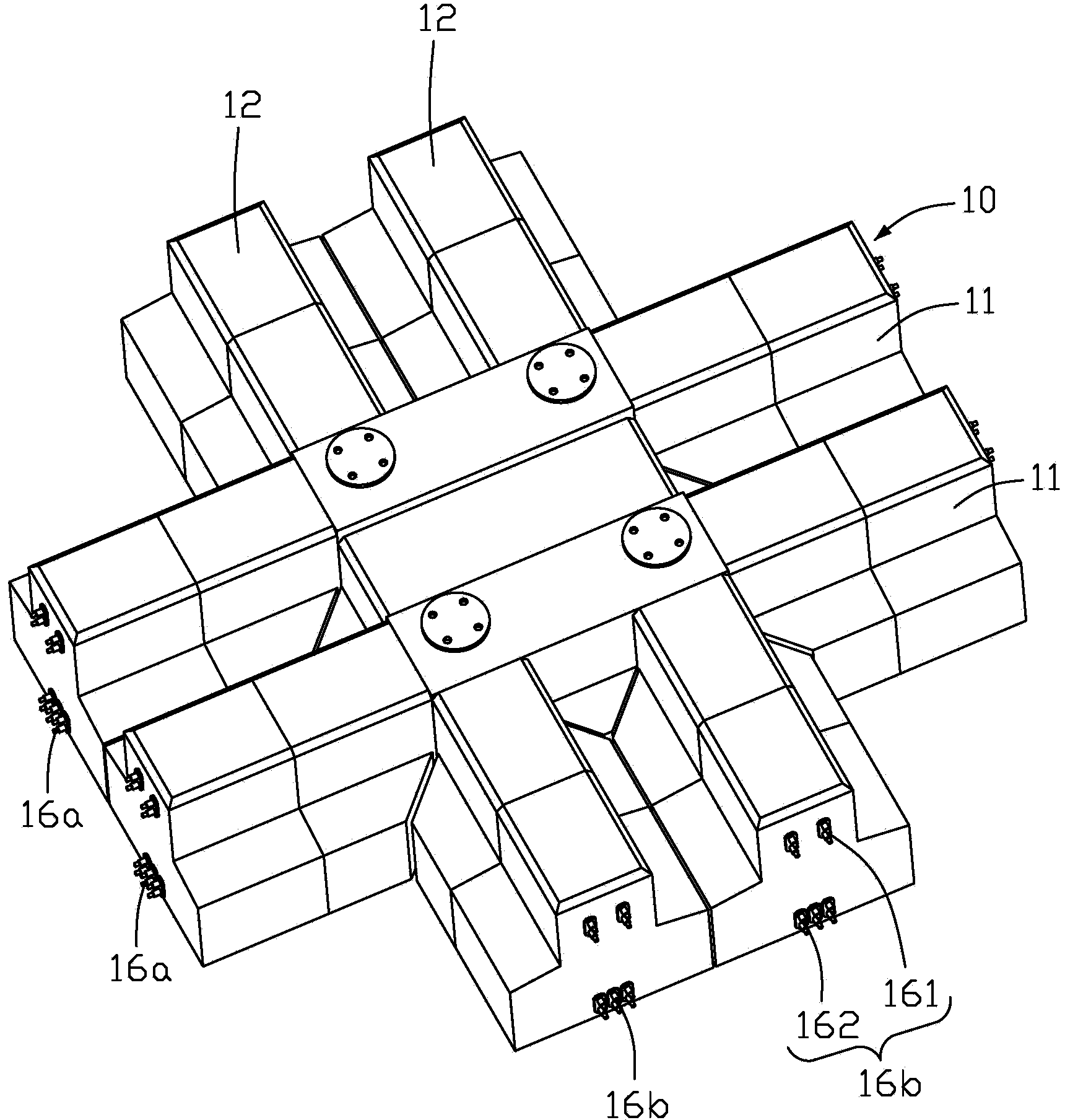

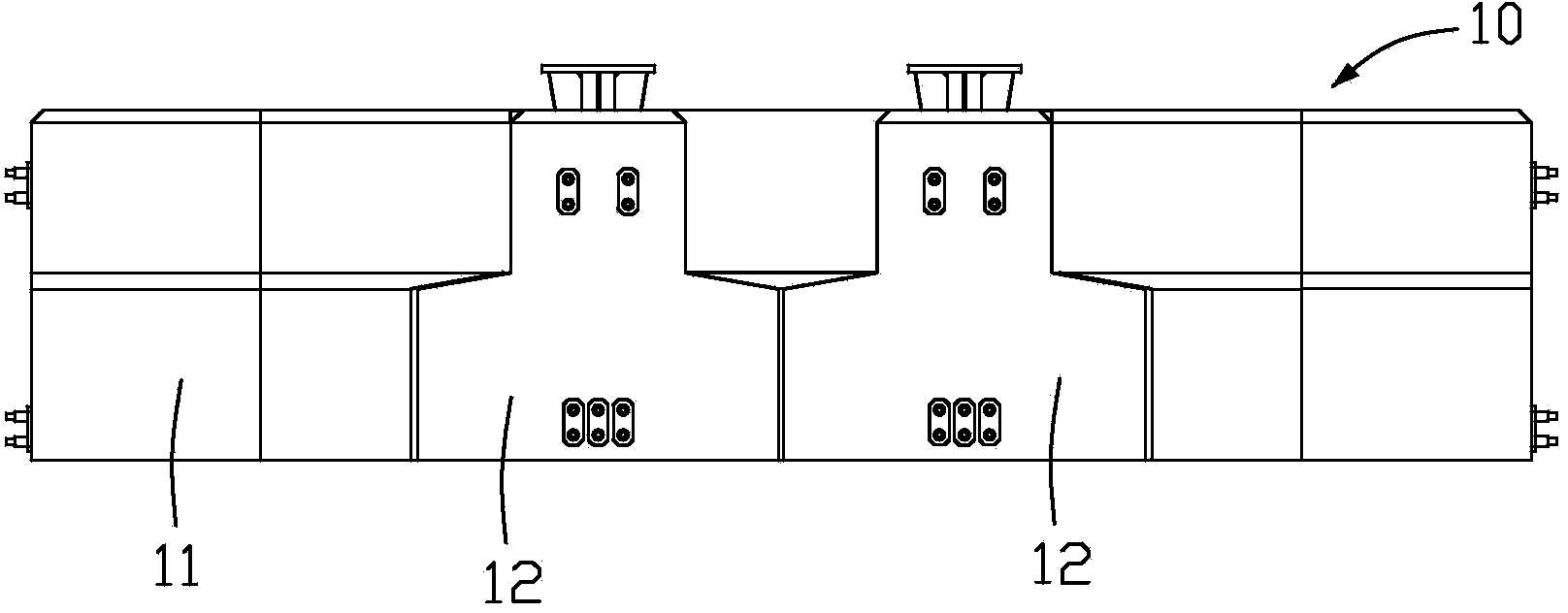

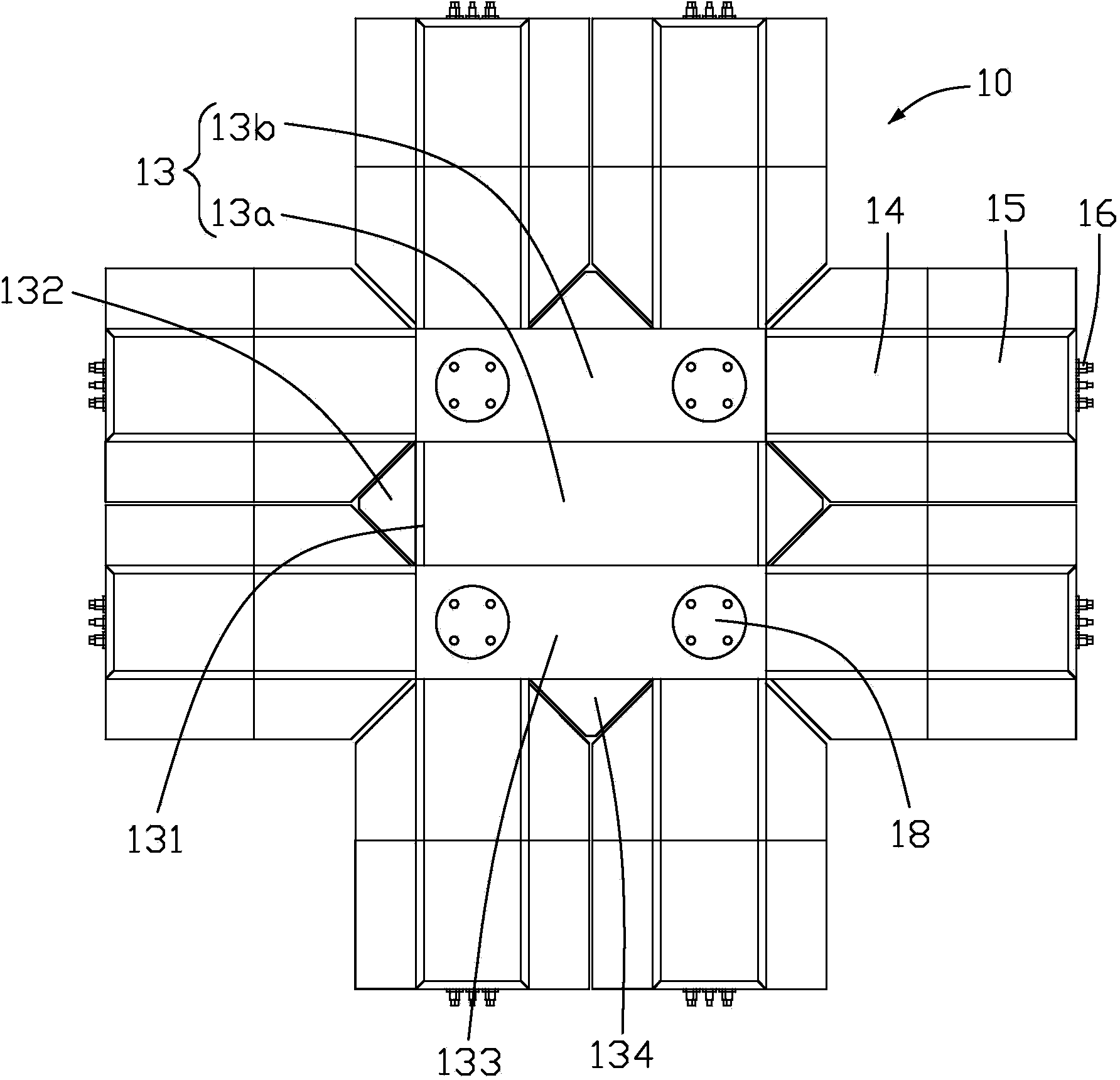

[0045] figure 1 It is a schematic diagram of the three-dimensional structure of the prefabricated and assembled tower crane foundation in the first embodiment of the present invention, figure 2 yes figure 1 The front view of the prefabricated tower crane foundation, image 3 yes figure 1 The top view of the prefabricated tower crane foundation, Figure 4 is in image 3 The distribution diagram of the steel strands in the prefabricated tower crane foundation is shown on the basis of Figure 1 to Figure 4 , the tower crane foundation 10 is formed by assembling concrete prefabricated parts, including two groups of first prefabricated foundations 11 parallel to each other in the transverse direction and two groups of second prefabricated foundations 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com