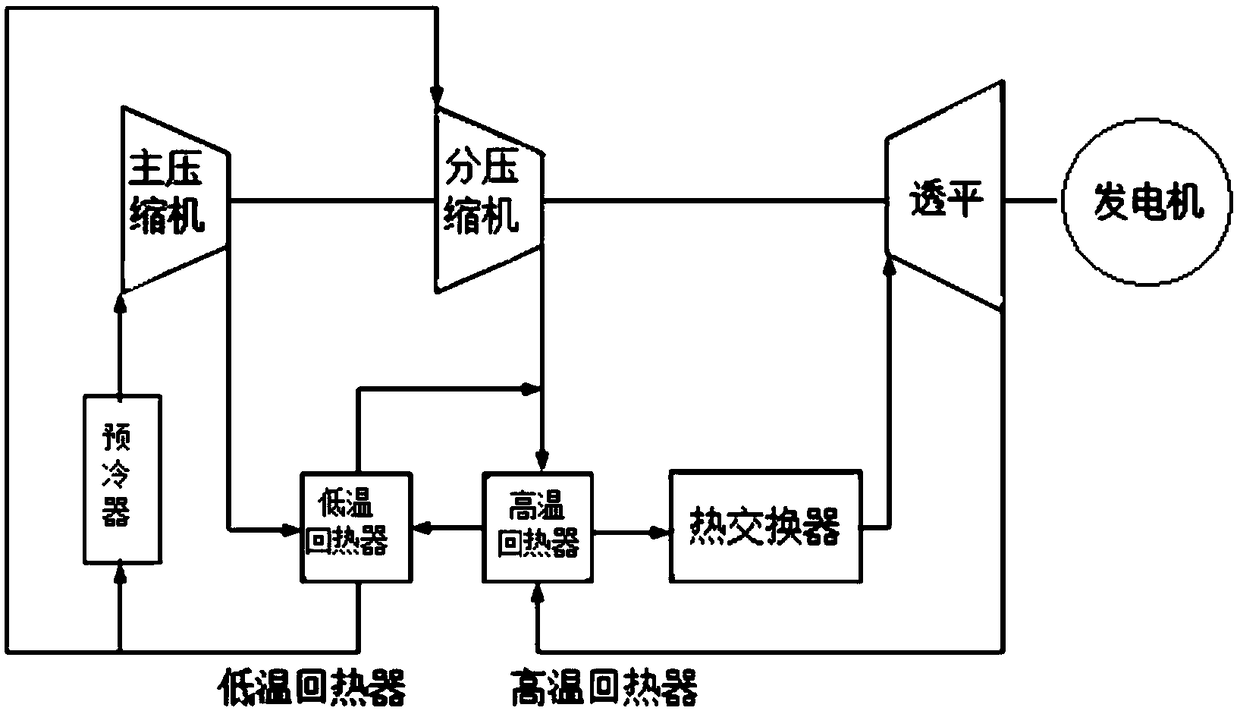

Compact type gas-gas heat exchange tube and manufacturing and use methods thereof

A compact heat exchange tube technology, applied in the field of heat exchange tubes, can solve problems such as inability to meet efficiency and volume requirements, and large heat exchange area, so as to reduce the overall weight of equipment and manufacturing costs, expand heat exchange surface area, and save equipment The effect of space size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

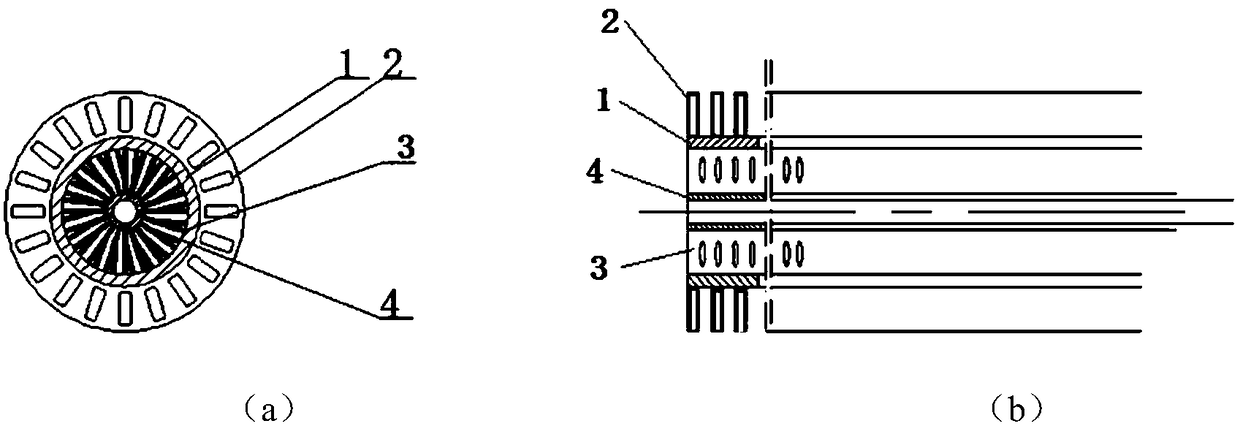

[0055] figure 2 The schematic diagram of the compact gas-gas heat exchange tube provided for this embodiment, the compact gas-gas heat exchange tube includes:

[0056] heat transfer tube 1;

[0057] The outer fin group 2 is arranged on the heat exchange surface outside the heat transfer tube 1 and forms a micro flow channel with an equivalent diameter of 0.5 mm to constrain the fluid outside the tube to flow along the axial direction of the heat transfer tube 1 . Each outer fin of the outer fin group 2 is a metal sheet radially parallel to the heat transfer tube 1, the width of the metal sheet is 1 / 4 of the inner diameter of the heat transfer tube 1, and the thickness is 1mm; each of the outer fin group 2 Each fin has holes. When the fluid outside the tube passes through the outer fins and the holes on the outer fins, it will produce a disturbance effect and enhance convective heat transfer;

[0058] It is arranged on the inner heat exchange surface of the heat transfer tub...

Embodiment 2

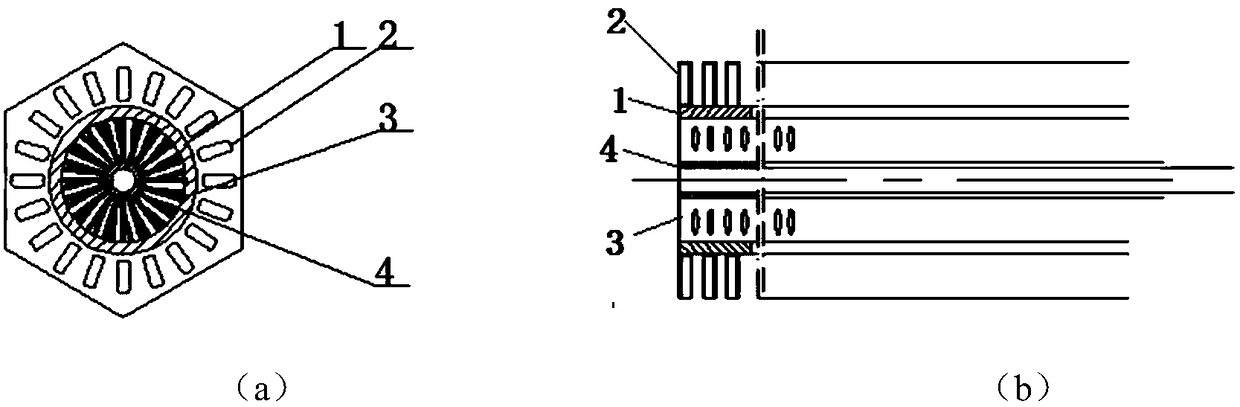

[0061] image 3 The schematic diagram of the compact gas-gas heat exchange tube provided for this embodiment, the compact gas-gas heat exchange tube includes:

[0062] heat transfer tube 1;

[0063] The outer fin group 2 is arranged on the outer heat exchange surface of the heat transfer tube 1 and forms a micro flow channel with an equivalent diameter of 0.5 mm to 1 mm to constrain the fluid outside the tube to flow along the axial direction of the heat transfer tube 1 . Each outer fin of the outer fin group 2 is a thin metal strip radially parallel to the heat transfer tube 1, the width of the metal thin band is 1 / 2 of the inner diameter of the heat transfer tube 1, and the thickness is 0.5mm, and the outer fin group 2 Each fin on the tube has a hole. When the fluid outside the tube passes through the outer fin and the holes on the outer fin, it will generate a disturbance effect and enhance convective heat transfer.

[0064] Set on the inner heat exchange surface of the h...

Embodiment 3

[0067] Figure 4 The schematic diagram of the compact gas-gas heat exchange tube provided for this embodiment, the compact gas-gas heat exchange tube includes:

[0068] heat transfer tube 1;

[0069] The outer fin group 2 is arranged on the outer heat exchange surface of the heat transfer tube 1 and forms a micro flow channel with an equivalent diameter of 2 mm to restrict the fluid outside the tube to flow along the axial direction of the heat transfer tube 1 . Each outer fin of the outer fin group 2 is a metal sheet radially parallel to the heat transfer tube 1, the width of the metal sheet is 1 / 3 of the inner diameter of the heat transfer tube 1, and the thickness is 1.5mm. Each fin has an elliptical hole, and when the fluid outside the tube passes through the outer fin and the holes on the outer fin, it will produce a disturbing effect and enhance convective heat transfer.

[0070] It is arranged on the inner heat exchange surface of the heat transfer tube 1 and forms a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com