Thermal mixing heat network heater

The utility model relates to a heating network heater and a heat-mixing technology, which is applied to heating the heating network. , In the field of hot-mixed heat network heaters, it can solve the problems of low heat transfer efficiency, small pressure loss and large pressure loss of heat network heaters, and achieve the effects of reasonable and compact structure, reduced effective heat exchange area and low resistance loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

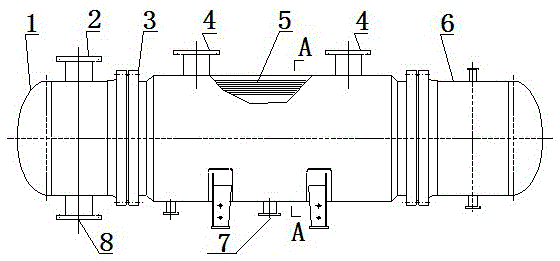

[0016] Such as figure 1 As shown: the heat network heater includes a left tube box 1 and a right tube box 6, and the tube sheet shell welding 3 arranged in the middle of the left tube box 1 and the right tube box 6 is arranged inside the tube sheet shell welding 3 The tube bundle 5.

[0017] The left tube box 1 is provided with an inlet 8 of secondary network circulating water and an outlet 2 of secondary network circulating water, and the tube plate shell welding 3 is provided with a steam inlet 4 and a steam outlet 7 .

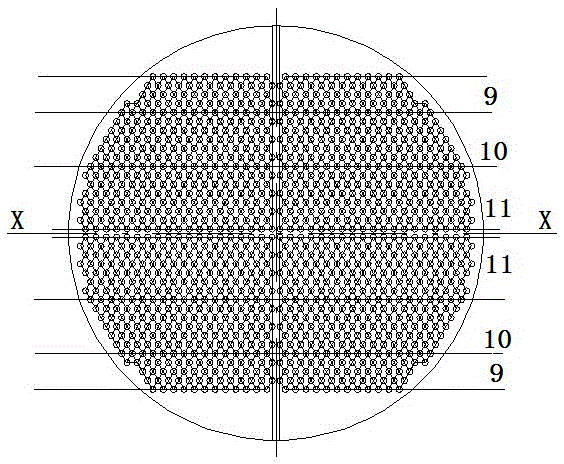

[0018] Such as figure 2 As shown: the tube bundle 5 is divided into three areas, namely the low resistance area 9 close to the upper and lower ends of the shell, the high resistance area 11 close to the center line of the tube bundle, and the high resistance area set between the high resistance area and the low resistance area. In the transition zone 10, the three zones are symmetrically arranged up and down relative to the horizontal centerline X-axis. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com