Efficient gas cooking appliance with backheating function

A gas cooker and functional technology, applied in the direction of heating fuel, gaseous heating fuel, household cooking utensils, etc., can solve the problems of indoor smoke pollution, low thermal efficiency of gas cooker, etc., and achieve the effect of high heat transfer power and high heat transfer temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

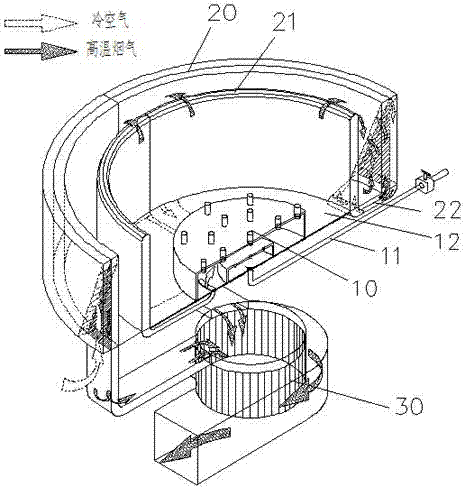

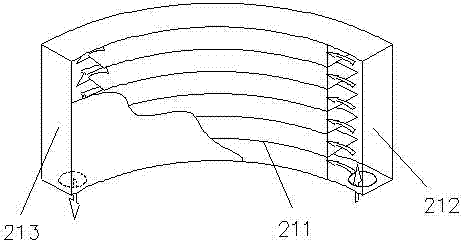

[0057] Please refer to figure 1 , a high-efficiency gas cooker with a heat recovery function, including a combustion zone, an enclosed heat exchange area, and a pot placement area for placing cooking pots 50. In this embodiment, between the combustion area and the enclosed heat exchange area They are connected by an inner cavity partition 12, and the present invention does not limit the material of the inner cavity partition. The enclosed heat exchange area is located outside the combustion area, and the pot storage area is set above the combustion area and the enclosed heat exchange area. In order to improve the heat utilization rate of the high-temperature flue gas, the high-temperature flue gas is exchanged with the bottom of the cooking pot to reduce the temperature. The resulting medium-temperature flue gas exchanges heat with the combustion-supporting cold air, and passes the hot air formed by heating the cold air to the stove 10. The specific structure is as follows:

...

Embodiment 2

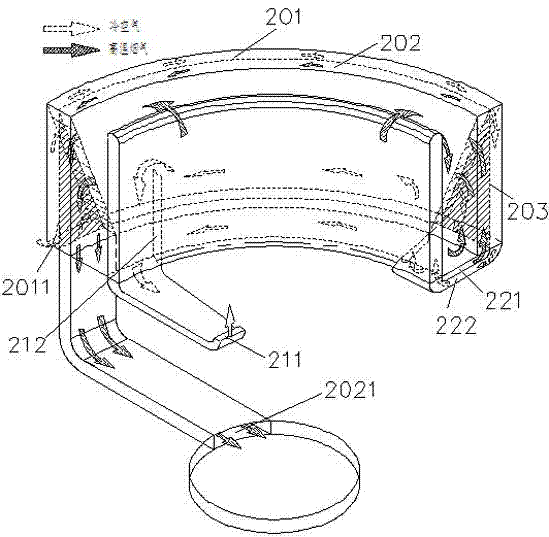

[0077] Please refer to Figure 9 and Figure 10 , a high-efficiency gas cooker with a heat recovery function, including a combustion area, an enclosure area and a pan area for placing cooking pots, the enclosure area is located outside the combustion area, and the pan area is set between the combustion area and the enclosure Above the area, in order to improve the heat utilization rate of the high-temperature flue gas, the medium-temperature flue gas obtained by exchanging the high-temperature flue gas with the bottom of the cooking pot and cooling down the temperature is exchanged with cold water, and the cold water is heated to form sanitary hot water for people to use . In order to further improve the heat utilization rate of the high-temperature flue gas, the present invention also utilizes the low-temperature flue gas (flue gas tail gas) discharged from the cooker, and conducts heat exchange with tap water through a tube-fin heat exchanger, and converts the cold tap wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com