Rib-line-type radiator and manufacturing method

A manufacturing method and heat sink technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of large size, heavy heat sink products, waste of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

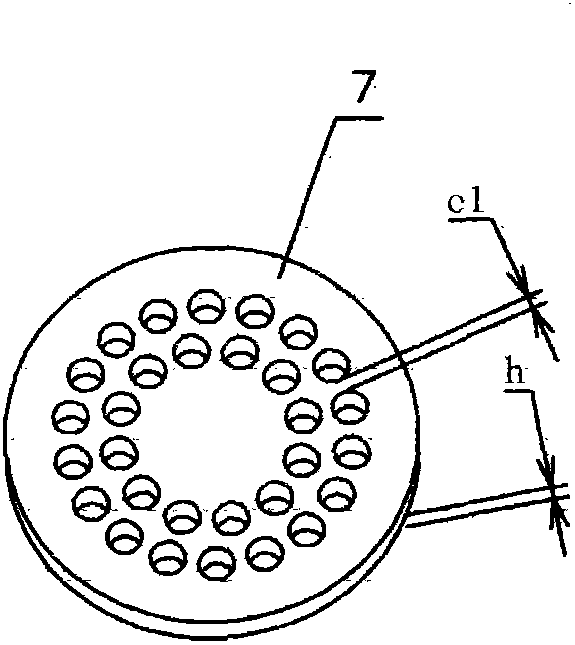

[0016] figure 1 , 2 Respectively show the three-dimensional schematic diagrams of the hoop 1 used in the rib wire radiator of the present invention or the heat conduction fixing plate 7 adopted, all adopt high thermal conductivity metal material aluminum, or copper, or copper-aluminum composite material, and the hoop 1 adopts It is formed by extrusion process, and then cut into sections. The thermally conductive fixed plate 7 is made by stamping process, and several holes are evenly arranged on it, and the surface is nickel-plated.

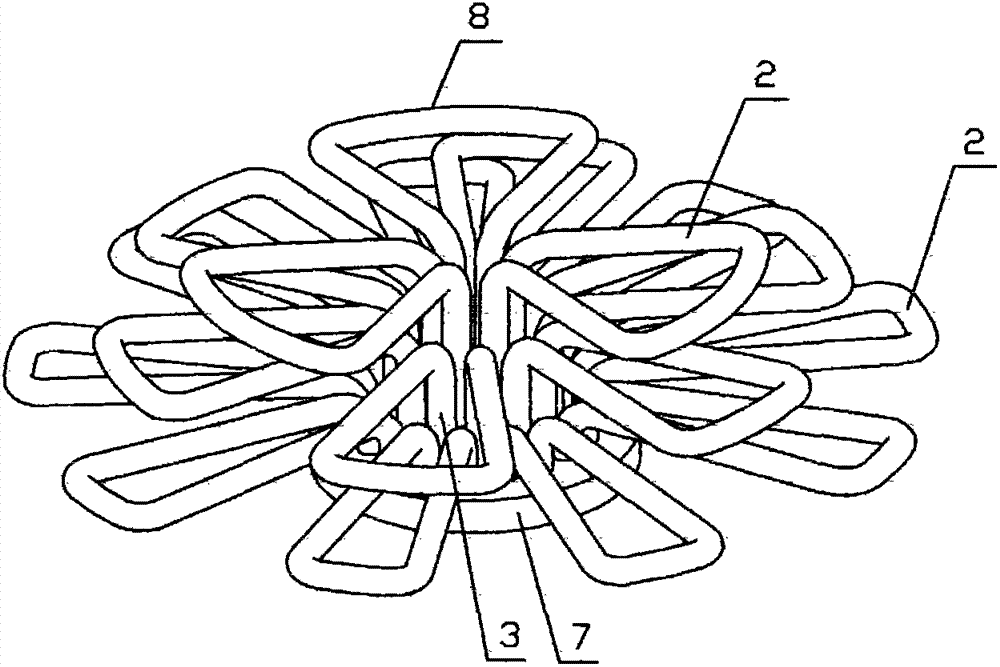

[0017] Figure 3a , 4a , 5a, 6a, 7 and Figure 3b , 4b , 5b, and 6b are three-dimensional views and three-dimensional cut-away schematic diagrams of three rib-wire radiators of the present invention, respectively. The rib-wire radiator shown in Fig. The heat conduction fixed plate 7 consists of several ribs 8 and the rib feet 3 are inserted into the heat conduction fixed plate 7. The ribs 8 and the heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

| Average clearance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com