Condenser

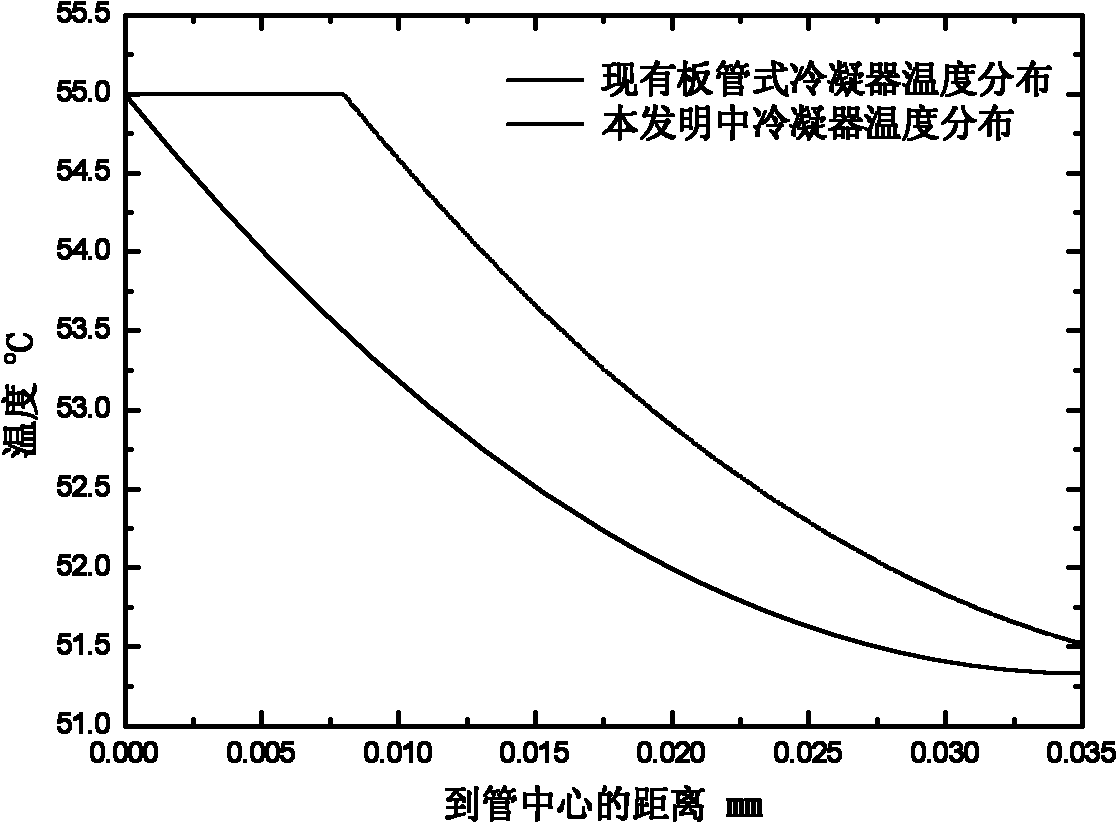

A technology of a condenser and a condensing section is applied to the field of built-in condensers, which can solve problems such as the influence of heat transfer efficiency, and achieve the effects of improving the convective heat transfer coefficient in the tube, improving the refrigeration efficiency, and improving the radiation heat transfer coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

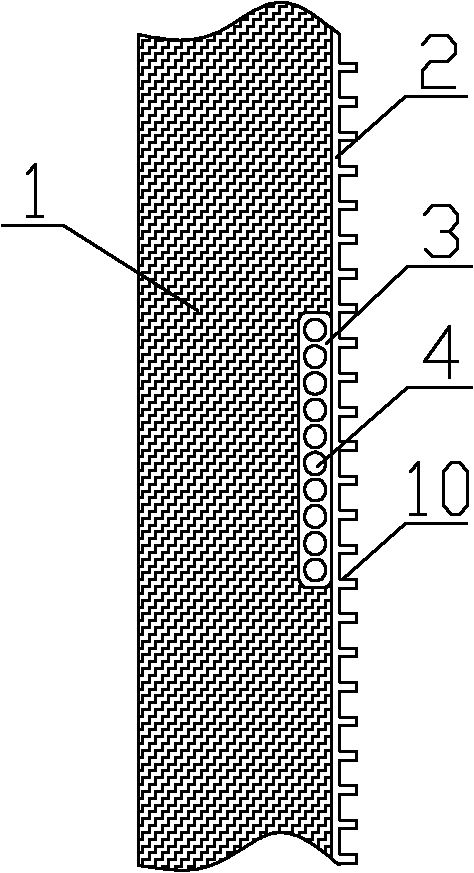

[0024] Example 1: see figure 1 , 3, this embodiment includes a heat dissipation backplane 2 and a number of porous microchannel heat exchange flat tubes 3 closely attached to the inside of the heat dissipation backplane 2 through thermally conductive silicone grease. The outer surface of the heat dissipation backplane 2 can be set to increase the heat exchange area The expanded fin 10 of the present invention uses thermally conductive silicone grease to reduce the contact thermal resistance. The thermal insulation foam layer 1 presses several porous microchannel heat exchange flat tubes 3 to the inside of the heat dissipation back plate 2. The porous microchannel The hot flat tube 3 has a plurality of parallel channels 4 with a circular cross section, a square cross section or a special cross section with an equivalent diameter of 0.8-1.2 mm along the same fluid flow direction. In order to enhance the heat exchange, the present invention can also add internal teeth in the parall...

Embodiment 2

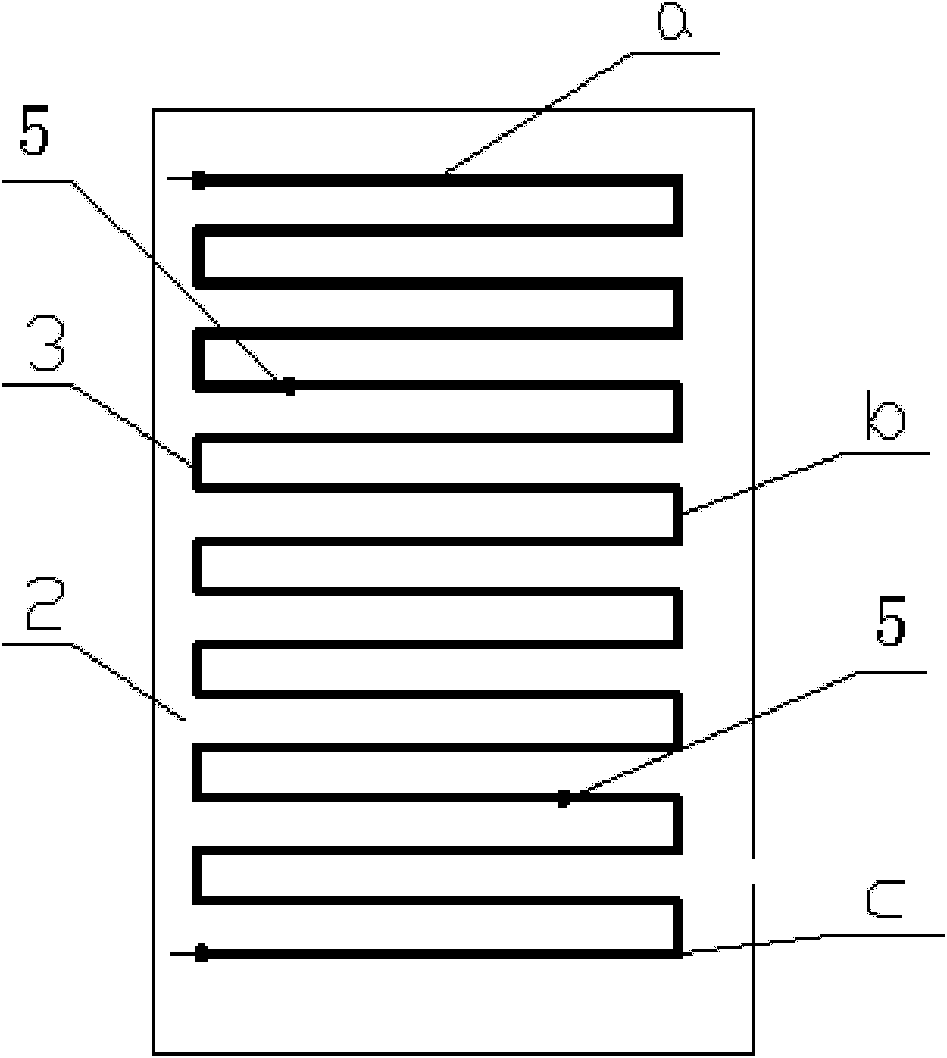

[0027] Example 2: see Figure 4 , This embodiment includes a heat dissipation backplane 2 and a number of porous microchannel heat exchange flat tubes 3 tightly attached to the inside of the heat dissipation backplane 2 through thermally conductive silicone grease. The thermal insulation foam layer 1 connects the plurality of porous microchannel heat exchange flat tubes 3 Press tightly to the inside of the heat dissipation back plate 2. The porous micro-channel heat exchange flat tube 3 has several circular cross-sections, square cross-sections or irregular cross-sections parallel to the same fluid flow direction with an equivalent diameter of 0.8-1.2mm. Channel 4. The porous microchannel heat exchange flat tubes 3 of the superheated cooling section a, the two-phase cooling section b and the supercooled condensing section c of the condenser are arranged in parallel and horizontally, and each section is arranged on both sides of the porous microchannel heat exchange flat tubes 3 ...

Embodiment 3

[0028] Example 3, see Figure 5 In this embodiment, the superheated cooling section a, the two-phase condensing section b, and the supercooling cooling section c of the condenser composed of porous microchannel heat exchange flat tubes 3 are arranged vertically in parallel. Other connections are the same as in Example 2.

[0029] See Figure 4 , 5, the high-temperature and high-pressure refrigerant vapor from the compressor first enters the distribution pipe 6, under the action of the baffle 8, enters the porous microchannel flat tube condenser 3, and then enters the collector 7, because the refrigerant is superheated vapor at this time , The specific volume is larger, so more porous micro-channel flat tube condenser 3 is used to cool to the saturated gas, and the position of the baffle 8 in the distribution pipe 6 and the collecting pipe 7 is changed, and fewer porous micro-channel flat tubes are used. The tubes are arranged in parallel to ensure that the refrigerant has a suffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com